c.

Radio Frequency Interference

can

be

particularily

troublesome

with

low-current

thermoelements.

The

thermocouple in the Model 540B

is

incased

in

a

steel

shield

to

minimize

stray

field

pick

- up.

However,

to

insure

accuracy,

the

Model 540B

should

be

used

in

areas

of

relatively

low

field

strength.

d. The number of

transfers

will

vary

with the degree

of

accuracy

required.

In

general

it

is

suggested

that

three

seperate

transfers

(de to

ac

and back

to

de constitutes one

transfer)

be

made for any single

measurement. This will be adequate only if a good

degree

of

repeatability

is

achieved. Difficulty in

repeating

any

measurement

can

be

caused

by any

number

of

problems,

the

most

common of which

are

poor collllections, unstable

sources,

and

inter-

ference

from

stray

capacitance

or

energy

fields.

Any

factor

which

detracts

from

repeatability

must

be

eliminated

before

accurate

transfers

can

be

made.

e.

All

of

the

components and

elements

in the Model

540B have been selected

to minimize environmental

sensitivity.

It

is

suggested that the Model 540B be

given

time

enough to

arrive

at

the

environmental

temperature

before

it

is

used.

If

the Model 540B

is

used

before

it

has

arrived

at

the

temperature

of

the

environment

where

it

is

to

be

used,excessive

thermal

drift

will

be

observed

making

accurate

transfers

more

difficult.

f. The Model 540B imposes

two

load conditions on

the

ac

source.

The

ac

source

sees

the

182

ohms/volt

input impedance of the Model 540B when

the

MODE

switch

is

in the

AC

TRANSFER position. When the

MODE

switch

is

in

the

OFF

or

DC

TRANSFER

positions,

the

ac

source

sees

the

Model 540B

as

an

open

cir

c

uit.

This

impedance

change

across

the

ac

source

causes

a corresponding output

level

change

from

the

ac

source

. When

calibrating

a

device that

is

quite sensitive to

level

changes, the

user

should determine

if

the ac source level changes

could adversely affect the device. The

user

should

take appropriate precautions, such

as

switching the

device out of the calibration

circuit

before turning

the

MODE

switch

to

the

OFF

or

DC

positions,

should such a situation

arise

.

g.

Though the internal range selection components

and

thermocouple in the Model 540B

are

protected

from

overloads in

the

voltage mode;

no

protection

is

pro-

vided in the

current

mode

or

for external shunts

or

high

frequency

converters.

These

devices

are

easily

damaged

or

destroyed

by

overloads

and

all

STEP

CONTROL

POSITION

a POWER

REFERENCE

GALVO

SEARCH

540B

possible precautions should

be observed. External

switching

transients

cause

many

such

overloads

and should be avoided.

It

is

possible

to

damage a

thermal

converter without completely destroying it.

One

of the

characteristics

which change, and indi-

cate

a

damaged

thermal

element,

is

de

reversal

error.

Should

the

reversal

error

of any

thermal

element

change

after

a

suspected

overload

it

is

reasonable

to

assume

that

damage

has

occurred

and

the

device

should be

recalibrated.

h.

During

all

transfer

measurements

the

operator

must

remain

alert

to

changes in readings

regard-

less

of

their

cause.

All

such

changes should be

analyzed and

corrective

measures

taken, in

order

to

insure

the

accuracy

of

the

transfer

measure-

ments.

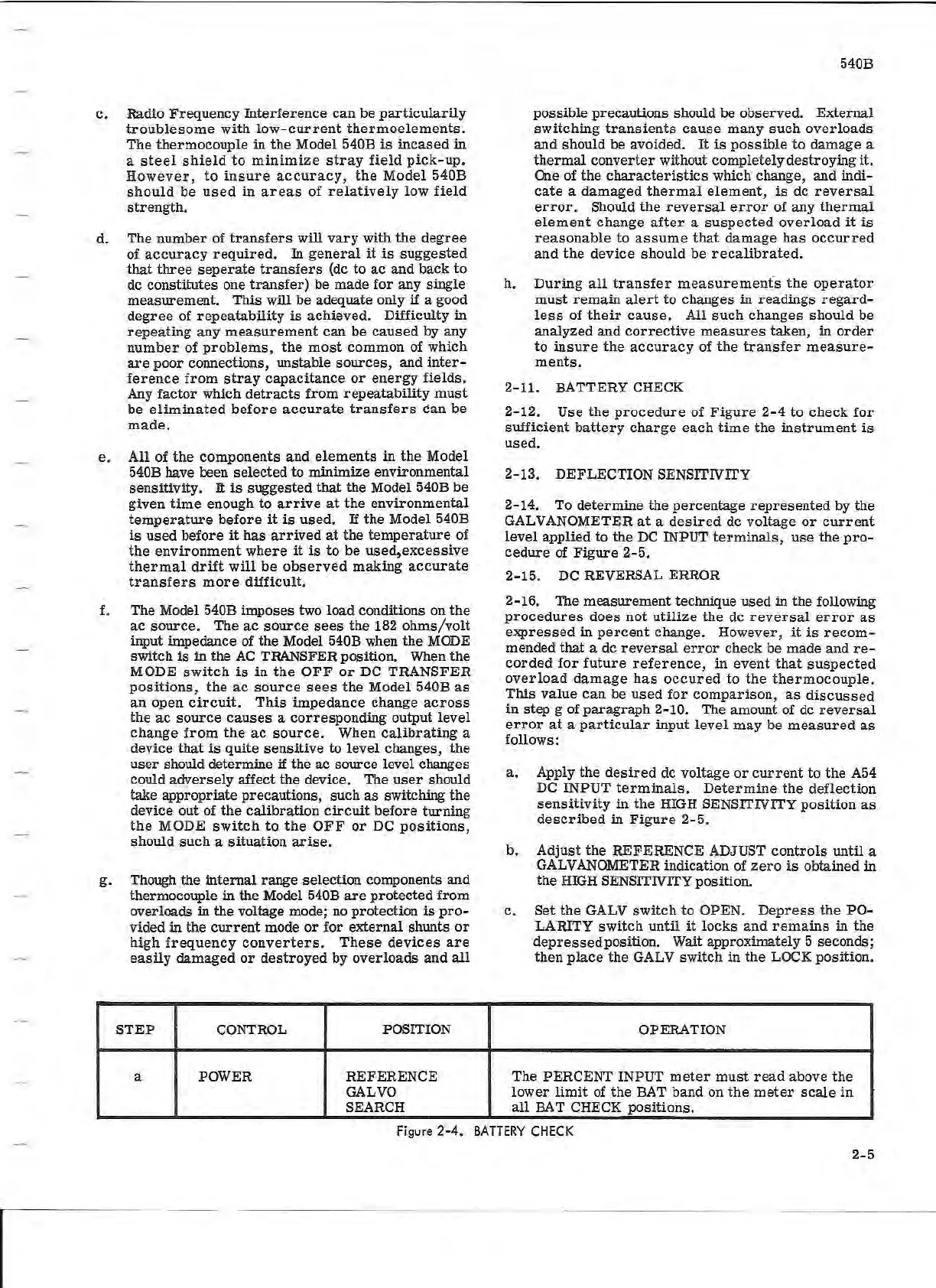

2-11. BATTERY CHECK

2- 12. Use

the

procedure

of

Figure

2-4

to check

for

sufficient

battery

charge

each

time

the

instrument

is

used.

2-13. DEFLECTION SENSITIVITY

2-14. To determine the percentage

represented

by the

GALVANOMETER

at

a

desired

de voltage

or

current

level

applied

to

the

DC

INPUT

terminals,

use the

pro

-

cedure

of

Figure

2-

5.

2-15.

DC

REVERSAL ERROR

2-16. The measurement technique used in the following

procedures

does

not

utilize

the de

reversal

error

as

expressed

in

percent

change. However,

it

is

recom-

mended that a de

reversal

error

check be made and

re

-

corded

for

future

reference,

in event

that

suspected

overload

damage

has

occured

to

the

thermocouple.

This

value

can

be

used

for

comparison,

as

discussed

in step g of paragraph 2-10. The amount of de

reversal

error

at

a

particular

input

level

may be

measured

as

follows:

a. Apply the

desired

de voltage

or

current

to the

A54

DC

INPUT

terminals

.

Determine

the

deflection

sensitivity

in

the

HIGH

SENSITIVITY

position

as

described

in

Figure

2- 5.

b.

Adjust

the

REFERENCE ADJUST

controls

until a

GALVANOMETER indication of

zero

is

obtained in

the

HIGH

SENSITIVITY position.

c. Set the GALV switch to OPEN.

Depress

the

PO-

LARITY

switch

until

it

locks and

remains

in the

depressedposition. Wait approximately

5 seconds;

then

place

the GALV switch in

the

LOCK position.

OPERATION

The PERCENT INPUT

meter

must

read

above

the

lower

limit

of

the

BAT

band on

the

meter

scale

in

all

BAT

CHECK positions.

Figure 2-4.

BATTERY

CHECK

2-5

Loading...

Loading...