3-17.

Resetting

the

Protection

Amplifier

is

accom-

plished

by cutting off the voltage

to

it. It

is

always

ad-

visable to determine the cause of the overload before

at-

tempting

to

reset

the

circuit.

The voltage

may

be

cut-

off

to

the

Protection

Amplifier

by two

methods.

The

MODE

switch may be

placed

in

the

OFF position and

the

POWER

switch

may

be

operated

to

any

position

other

than

ON.

Either

of

these

actions

will

cause

an

inter-

ruption

in

the

battery

power to

the

Protection

Amplifier.

The

preferred

method

is

resetting

the

protection

cir-

cuit

with

the

MODE

switch.

3-1

.8. A

push

button,

momentary

open,

switch

called

PROTECTION DISABLE

is

located on

the

front

panel

of

the

Model A54- 2

plug-in

unit.

This

switch,

and

its

function,

constitutes

th

e

only

difference

between

the

Model A54

-1

and

the

Model A54-2

plug-in

units.

De-

pression

of

the

PROTECTION DISABLE switch

removes

the

diode

circuit

(CR701

thru

CR704)

in

parallel

with

the

thermocouple, providing a routine method of check-

ing

for

diode

leakage

(see

Section

4-31).

The

Model

A54-2

is

calibrated

with

the

diode

circuit

active

(PRO-

TECTION DISABLE switch in

the

normal,

up, position).

3-19.

THERMOCOUPLE

3-20.

The

thermocoupl

e e

lement

has

been

tested

and

selected

at

the

factory

and

placed

in

an insulating

case

with

a

standard

octal

plug

base.

The

thermocouple

element

is

of

the

high

vacuum,

insulated

type

with

a

nominal output

of

7 millivolts

at

rated

input. The Model

A54 unit

will

have

to

be

rechecked

for

calibration

accu-

racy

if

the

thermocouple

is

replaced.

The input

to

the

thermocouple may be

reversed

by operating switch S802,

POLARITY, located

on

the

front

panel

of

the

Model

A54

plug-in unit. With

this

switch it

is

possible

to

check the

turn-over

error

of

the

thermocouple with a minimum of

effort.

MOMENTARY

INPUT

LOCK

540B

3-21.

REFERENCE

3-22.

When

using the

Transfer

Standard

it

is

not

neces-

sary

to

measure

th

e output voltage of the thermocouple,

it

is

necessary

only to provide a means of detecting and

comparing

the

thermocouple

output

accurately

when

making

transfer

measurements.

A

variable

voltage

source

has

been

designed

into

the

Model

540B

which

fulfills

the

stability and resolution

requirements

for

this

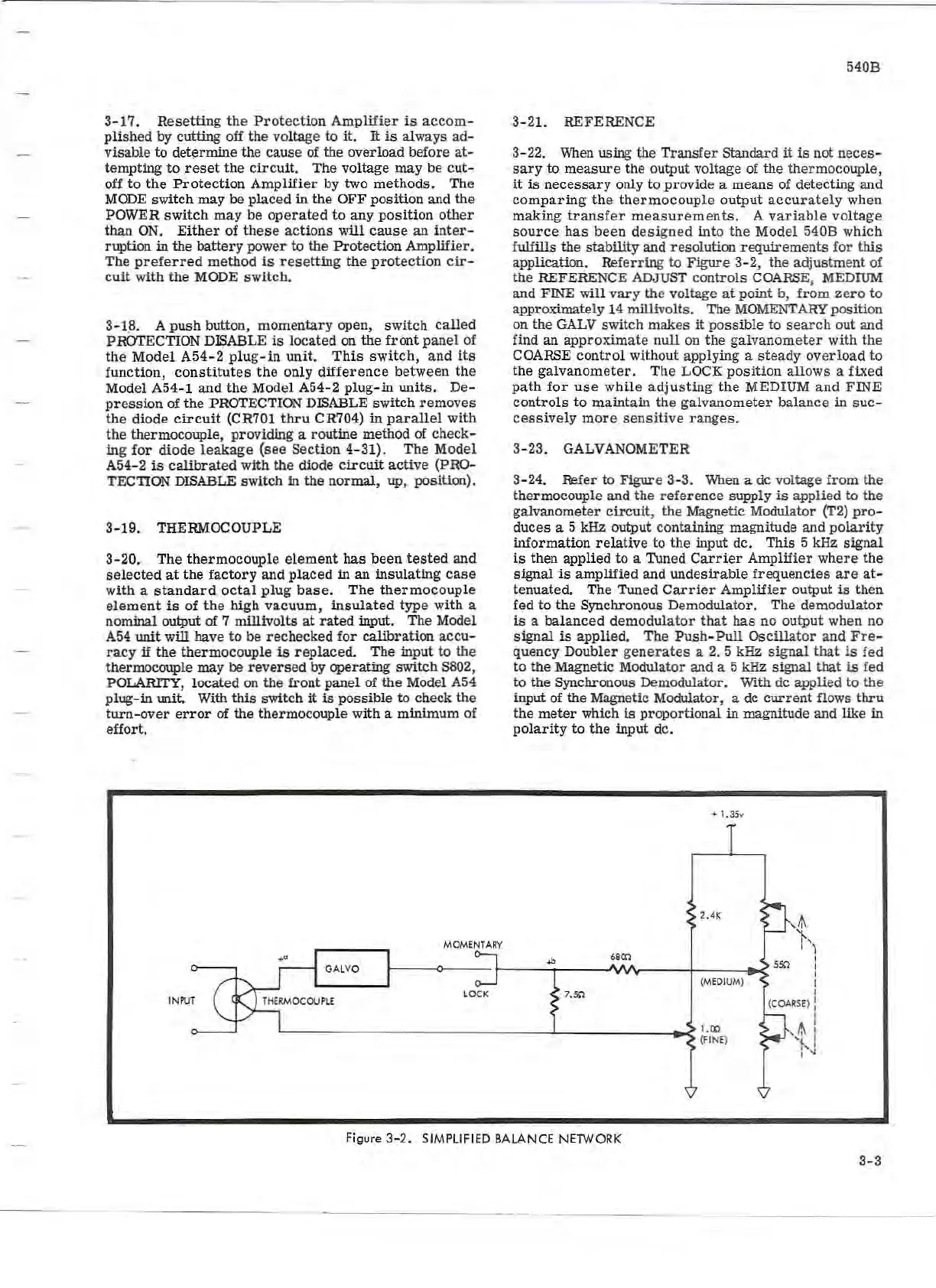

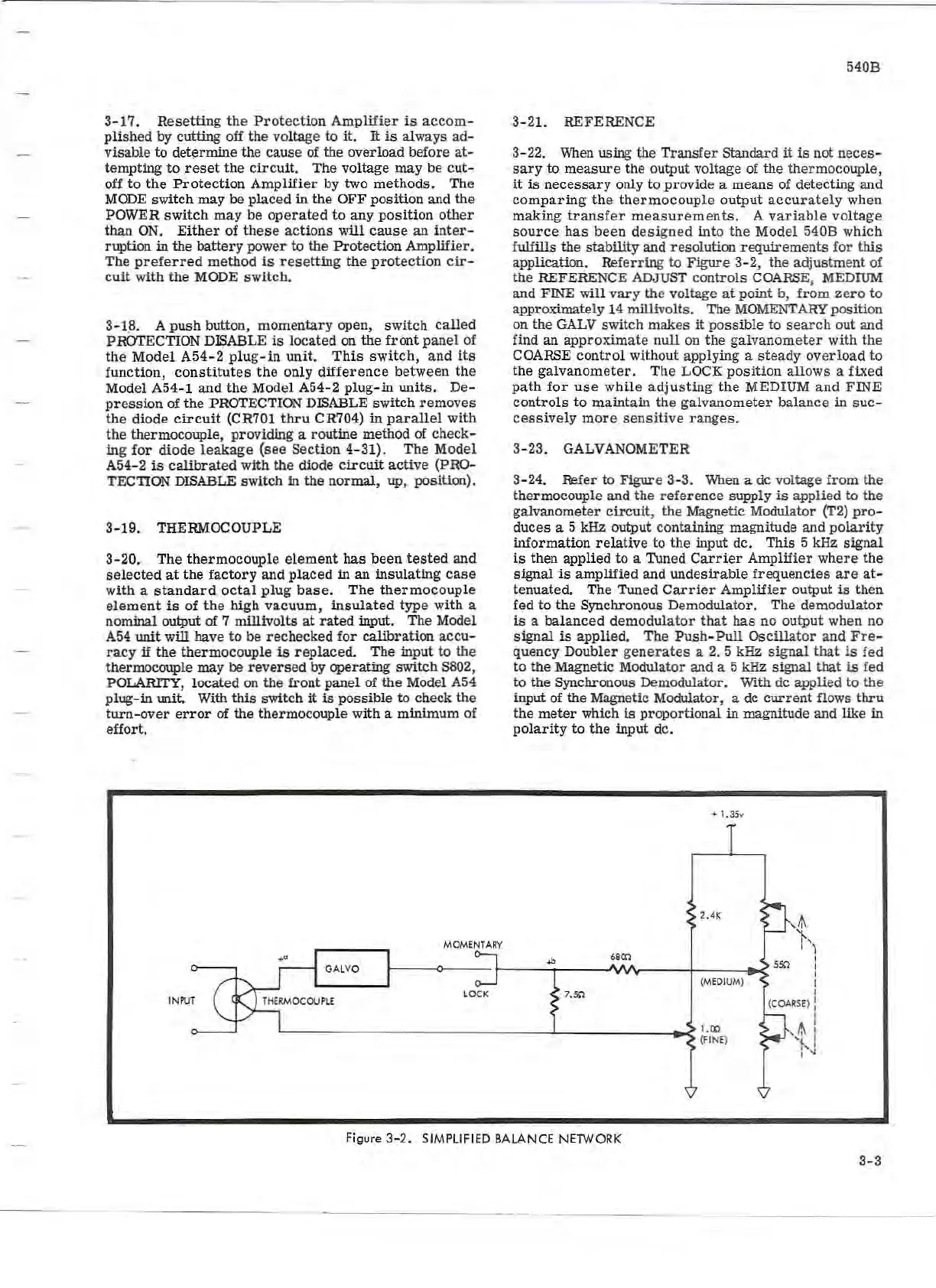

application. Referring to Figure

3-2,

the adjustment of

the

REFERENCE ADJUST

controls

COARSE, MEDIUM

and FINE will

vary

the

voltage

at

point b,

from

zero

to

approximately 14 millivolts. The

MOMENTARY

position

on the

GALV

switch makes

it

possible

to

search

out and

find an

approxim

ate

null

on

the

galvanometer

with

the

COARSE

control

without applying a

steady

overload

to

the

galvanometer.

The

LOCK

position

allows

a fixed

path

for

use

while

adjusting

the

MEDIUM

and

FINE

controls

to

maintain

the

galvanom

eter

balance

in

suc-

cessively

more

sensitive

ranges.

3-23.

GALVANOMETER

3- 24. Refer

to

Figure 3-3. When a de voltage

from

the

thermocouple and

the

reference

supply

is

applied

to

the

galvanometer

circuit,

the Magnetic Modulator (T2)

pro-

duces a 5 kHz output containing magnitude and

polarity

information

relative

to

the

input de.

This

5 kHz

signal

is

then applied

to

a ·Tuned

Carrier

Amplifier

where

the

signal

is

amplified and

undesirable

frequenci

es

are

at-

tenuated.

The

Tuned

Carrier

Amplifier

output

is

then

fed

to

the

Synchrono

us

Demodulator. The demodulator

is

a

balanced

demodulator

that

has

no

output

when no

signal

is

applied.

The

Push-Pull

Oscillator

and

Fre

-

quency

Doubler

generates

a 2.

5kHz

signal

that

is

fed

to

the

Magnetic Modulator and a 5 kHz

signal

that

is

fed

to

the Synchronous Demodulator. With de applied

to

the

input of

the

Magnetic Modulator, a de

current

flows

thru

the

meter

which

is

proportional in magnitude and like in

polarity

to

the

input de.

-+

1.l5

v

2.4K

680Ω

{MEDIUM)

7.5Ω

{FINE)

Figure

3-2.

SIMPLIFIED BALANCE NETWORK

3-3

Loading...

Loading...