5

1. Installation errors: failure to make proper connections while maintaining the wire

pairs and the twist rate in each pair (always keep the “original twist” in each wire

pair as much as practical)

2. Connectors that do not meet the required transmission quality

3. Incorrect tester set up

4. Defects or damage in the installed cable

5. Bad patch cords*

* Patch cords rate high on the list when we are discussing operating networks.

Certication is often executed using the Permanent Link Model since the actual patch

cords used by the operating network are not yet installed or available.

Before you begin testing, you should verify the basics:

• Has the correct test standard been selected? The certication test is executed as

an automated test or an “Autotest”. The test standard you select for an autotest

determines the link model (Permanent Link or Channel), the test parameters to

be measured and the frequency range over which the tests are executed and the

Pass/Fail criteria for each test.

• Has the correct link model been selected?

• Are you using the appropriate test adapter with a plug that matches the jack in the

telecommunication outlet (TO) or the patch panel?

• Has the test reference been set in the last 30 days? It is recommended to set the

reference on a regular basis and at a time that is easy to remember. (Such as at the

beginning of each testing session)

• Are you using the most current version of the tester software?

• Is the NVP set correctly for the cable under test? NVP plays a role when the tester

reports length or distance to a defect

• Is the tester within its operating temperature range and in calibration?

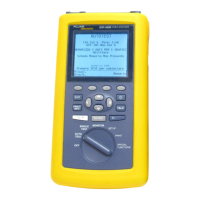

Remember that your Fluke Networks DSX-600 CableAnalyzer™ is a very accurate

instrument that measures small noise disturbances in cables. These instruments are

calibrated in the factory before shipping and this calibration should be veried every

12 months in an authorized Service Center. If the tester has been stored in a colder

or warmer place than the one in which you are working (i.e. overnight in a vehicle),

allow the unit to warm up to its steady-state operating temperature before setting

a reference or executing any measurements. This may take 10 to 15 minutes or more

depending on the temperature differential.

Troubleshooting Basics

Loading...

Loading...