Doc No: OMM50002312

Rev: C Page 1 of 54

Subject to contractual terms and conditions to the contrar

y, this document and all the information contained herein are the confidential and exclusive

property of FMC Technologies, and may not be reproduced

, disclosed, or made public in any manner prior to express written authorization by FMCTI.

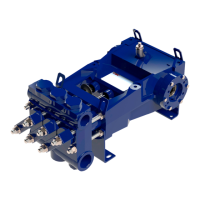

OPERATION AND MAINTENANCE MANUAL, W11 TRIPLEX PUMPS

Summary:

This is a manual for FMC W11 triplex piston pumps. These pumps include a pinion drive

for internal gear reduction; they have a stroke length of 2.75 inches, and maximum

continuous duty power ratings ranging from 20 horsepower (15 kilowatts) for the W1118

to 30 horsepower (22 kilowatts) for the W1122. The maximum intermittent duty rating is

24 horsepower (18 kilowatts) for the W1118 to 36 horsepower (27 kilowatts) for the

W1122. Refer to part number 5266226 for printing information.