Doc No: OMM50002312

Rev: C Page 28 of 54

Subject to contractual terms and conditions to the contrar

y, this document and all the information contained herein are the confidential and exclusive

property of FMC Technologies, and may not be reproduced

, disclosed, or made public in any manner prior to express written authorization by FMCTI.

10. Tighten all fasteners to the values specified in Fastener Torque Requirements,

Section 11.0 of this manual.

10.2 Removing the Fluid Cylinder

The fluid cylinder (34) may be removed to inspect for internal damage, to

be repaired, to replace the fluid cylinder, to replace damaged cylinders,

cylinder o-rings, or to service piston rod seals.

Refer to Figure 3 for illustration of parts.

FMC recommends that a sufficient quantity of clean water is pumped

through the fluid end before starting any service procedures that involve

fluid end components. This will remove most contaminants left in the

fluid cylinder by normal pumpage and improve the ability to work with

parts or see potential problems.

ENSURE THAT THE POWER IS LOCKED OUT AND TAGGED OUT

BEFORE SERVICING ANY PART OF YOUR FMC PUMP

1. Bleed off all pressure inside pump fluid end before starting

any service work. Shut the valve on the inlet piping if

provided to prevent flow of liquid from the source into the

pump during service.

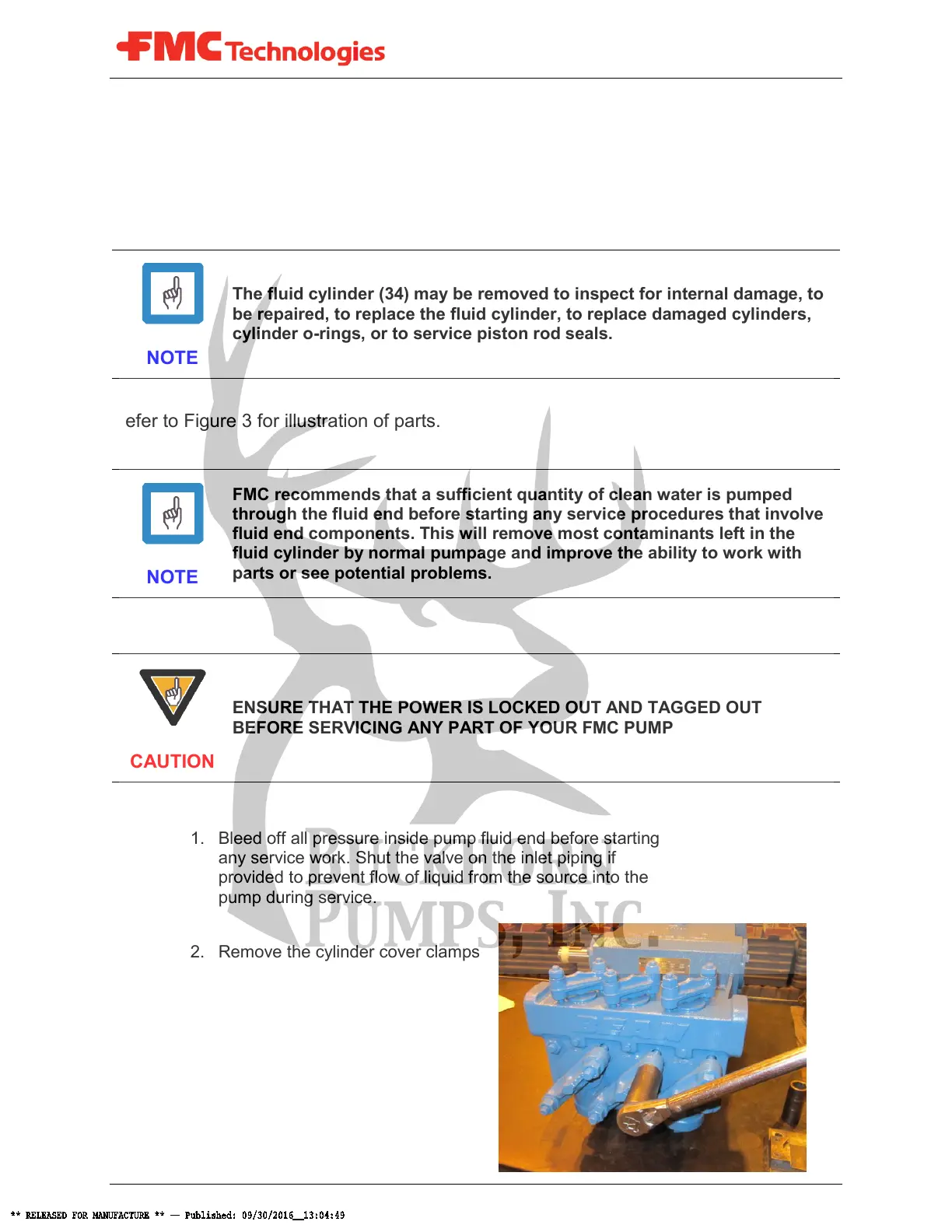

2. Remove the cylinder cover clamps

(43) and cylinder covers (41) as

described in the previous section.

Remove the outside corner fluid

cylinder nuts (52) if they are still in

place.

Loading...

Loading...