Doc No: OMM50002312

Rev: C Page 42 of 54

Subject to contractual terms and conditions to the contrar

y, this document and all the information contained herein are the confidential and exclusive

property of FMC Technologies, and may not be reproduced

, disclosed, or made public in any manner prior to express written authorization by FMCTI.

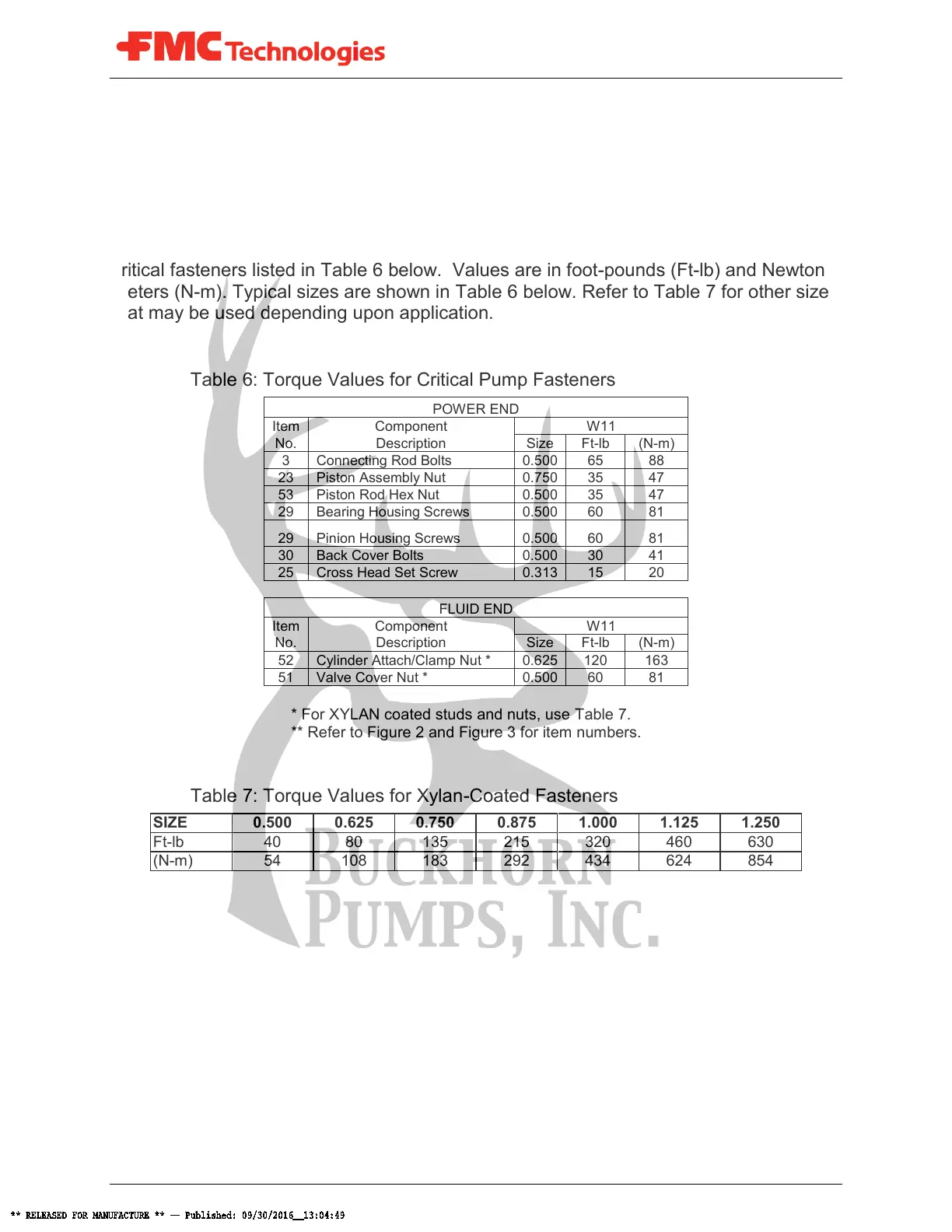

11.0 Fastener Torque Requirements

NOTICE: No pump service procedure is complete without ensuring that the fasteners

have been properly torqued. Failure to properly tighten the pump bolts could cause the

pump to leak or fail. Always use a calibrated torque wrench during the installation of all

critical fasteners listed in Table 6 below. Values are in foot-pounds (Ft-lb) and Newton

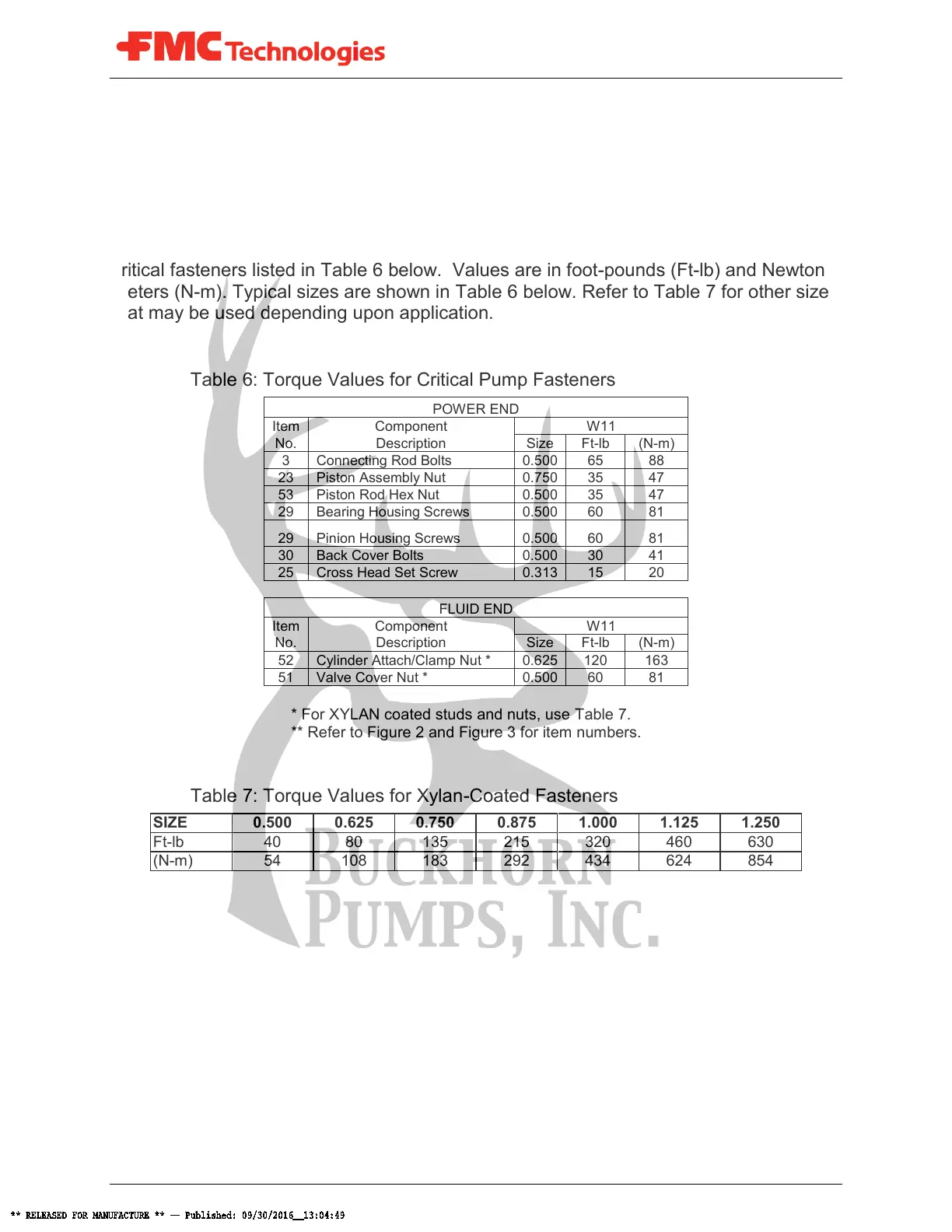

meters (N-m). Typical sizes are shown in Table 6 below. Refer to Table 7 for other sizes

that may be used depending upon application.

Table 6: Torque Values for Critical Pump Fasteners

Cylinder Attach/Clamp Nut *

* For XYLAN coated studs and nuts, use Table 7.

** Refer to Figure 2 and Figure 3 for item numbers.

Table 7: Torque Values for Xylan-Coated Fasteners

Loading...

Loading...