Doc No: OMM50002312

Rev: C Page 46 of 54

Subject to contractual terms and conditions to the contrar

y, this document and all the information contained herein are the confidential and exclusive

property of FMC Technologies, and may not be reproduced

, disclosed, or made public in any manner prior to express written authorization by FMCTI.

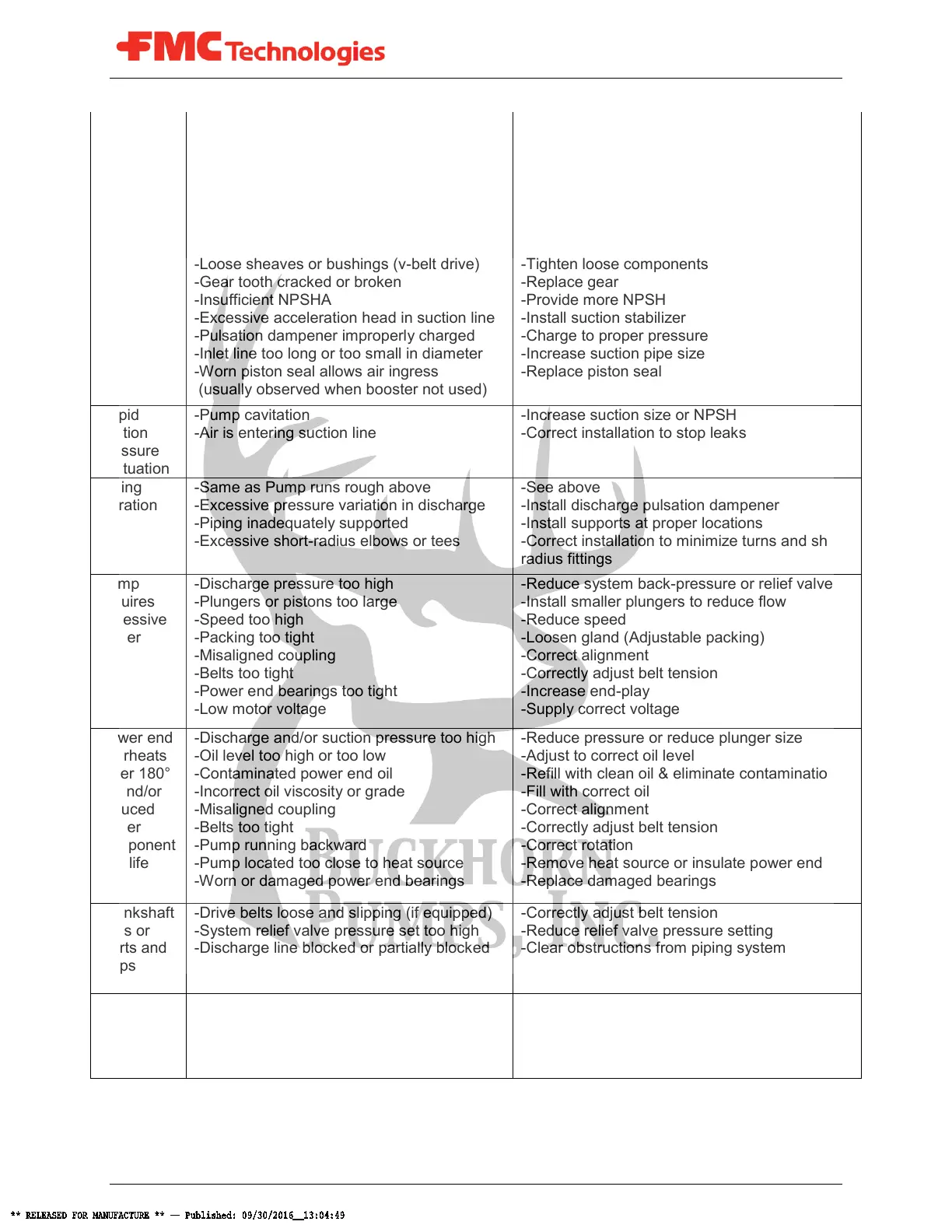

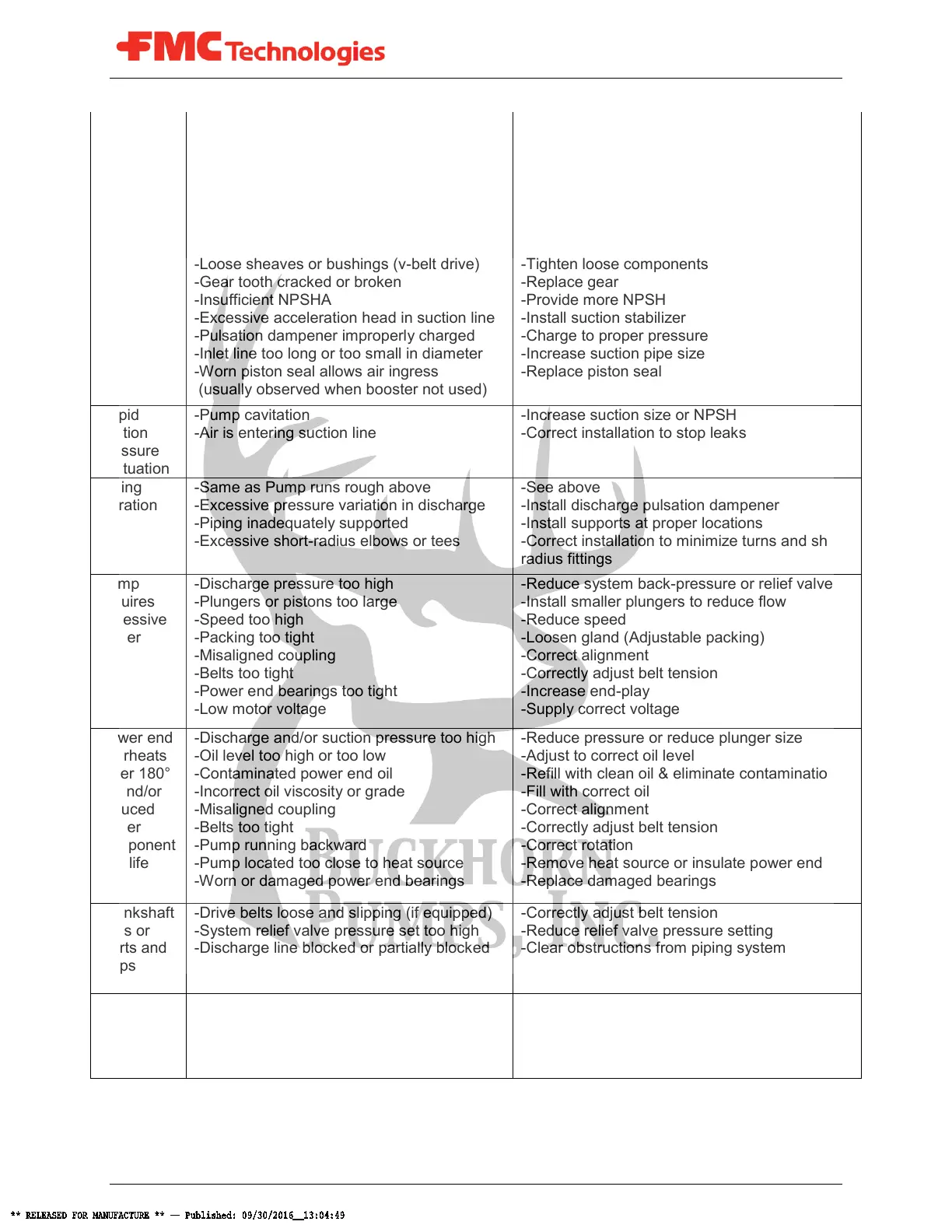

Pump runs

rough,

knocks, or

vibrates

(ONLY)

-Broken or weak valve spring

-Valve damaged or unseated

-Loose plunger, piston, or rod

-Low oil level in power end

-Excessive connecting rod bearing clearance

-Excessive main bearing clearance

-Worn wrist pin or bearing

-Pump running backward

-Loose sheaves or bushings (v-belt drive)

-Gear tooth cracked or broken

-Insufficient NPSHA

-Excessive acceleration head in suction line

-Pulsation dampener improperly charged

-Inlet line too long or too small in diameter

-Worn piston seal allows air ingress

(usually observed when booster not used)

-Replace valve spring

-Repair/replace valve or re-seat

-Tighten loose components

-Fill to proper level

-Check cap torque or replace bearings

-Adjust end-play

-Replace worn components

-Correct rotation

-Tighten loose components

-Replace gear

-Provide more NPSH

-Install suction stabilizer

-Charge to proper pressure

-Increase suction pipe size

-Replace piston seal

Rapid

suction

pressure

fluctuation

-Pump cavitation

-Air is entering suction line

-Increase suction size or NPSH

-Correct installation to stop leaks

-Same as Pump runs rough above

-Excessive pressure variation in discharge

-Piping inadequately supported

-Excessive short-radius elbows or tees

-See above

-Install discharge pulsation dampener

-Install supports at proper locations

-Correct installation to minimize turns and short-

radius fittings

Pump

requires

excessive

power

-Discharge pressure too high

-Plungers or pistons too large

-Speed too high

-Packing too tight

-Misaligned coupling

-Belts too tight

-Power end bearings too tight

-Low motor voltage

-Reduce system back-pressure or relief valve

-Install smaller plungers to reduce flow

-Reduce speed

-Loosen gland (Adjustable packing)

-Correct alignment

-Correctly adjust belt tension

-Increase end-play

-Supply correct voltage

Power end

overheats

(over 180°

F) and/or

reduced

power

component

end life

-Discharge and/or suction pressure too high

-Oil level too high or too low

-Contaminated power end oil

-Incorrect oil viscosity or grade

-Misaligned coupling

-Belts too tight

-Pump running backward

-Pump located too close to heat source

-Worn or damaged power end bearings

-Reduce pressure or reduce plunger size

-Adjust to correct oil level

-Refill with clean oil & eliminate contamination

-Fill with correct oil

-Correct alignment

-Correctly adjust belt tension

-Correct rotation

-Remove heat source or insulate power end

-Replace damaged bearings

Crankshaft

jerks or

starts and

stops

rotation

-Drive belts loose and slipping (if equipped)

-System relief valve pressure set too high

-Discharge line blocked or partially blocked

-Correctly adjust belt tension

-Reduce relief valve pressure setting

-Clear obstructions from piping system

-Piston cups are worn

-Piston to rod o-ring damaged

-Fluid cylinder bolts not properly tightened

-Fluid cylinder o-rings (or gaskets) damaged

-Replace piston cup

-Replace o-ring

-Properly tighten and torque bolts

-Replace damaged o-rings or gaskets

Loading...

Loading...