P a g e | 17

Check all hydraulic hoses and fittings after 5 hours’ work. Beware of hydraulic

oil leaks, they can cause serious injury while the engine is running and the

system is under pressure. A leak can easily inject high pressure oil deep into

flesh and blood stream requiring immediate medical attention. DO NOT

CHECK FOR LEAKS WHILE THE PTO IS ENGAGED. Hoses to the feed

roller hydraulic motors are the most likely to become damaged as they are

constantly moving during use. If hoses are replaced, all seals must be

replaced at the same time.

Check top and bottom feed motor bracket bolts weekly.

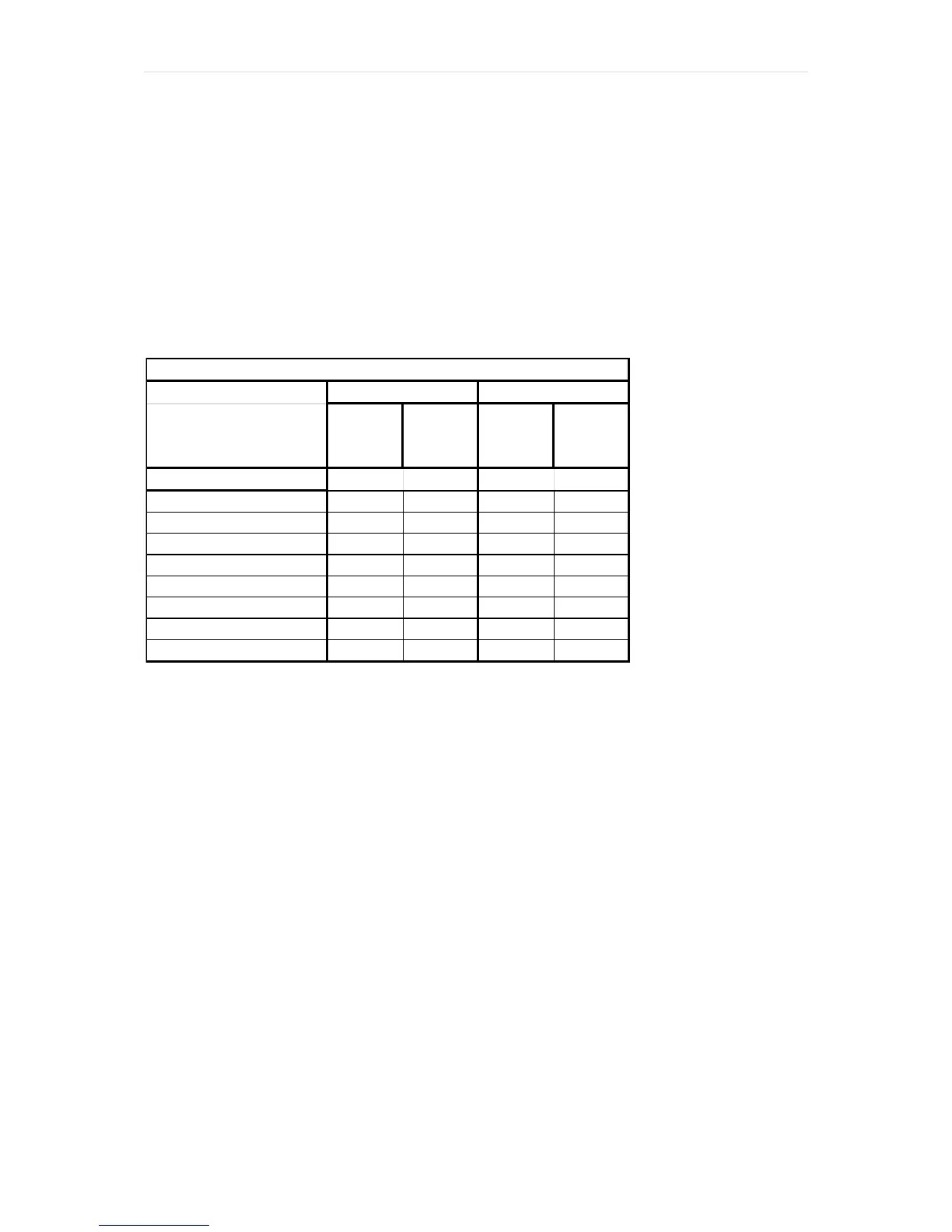

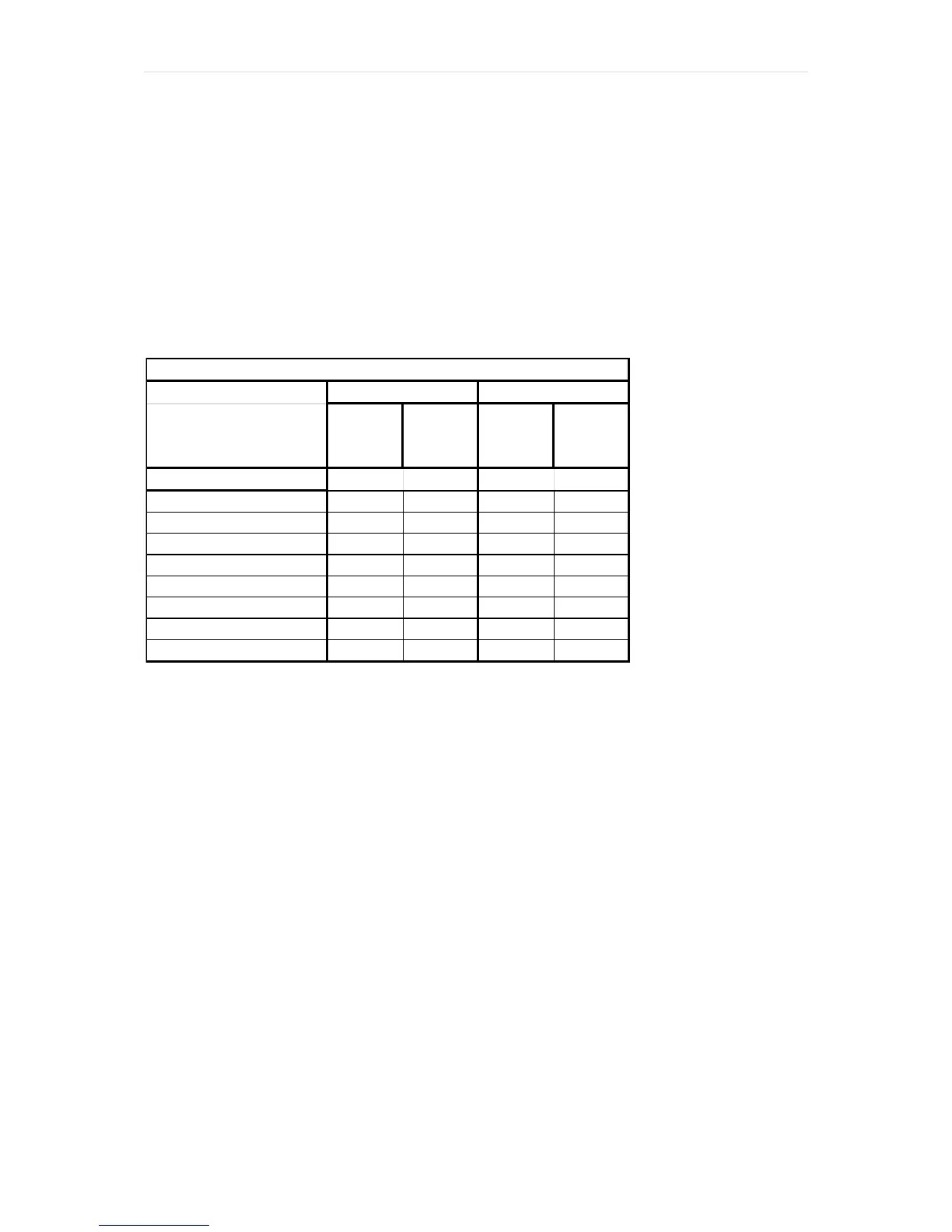

Fastener tightening torques

Size

M6 10 9.5/10.4 14.5 14/15.3

M8 25 23.1/25.3 35 34/37.2

M10 49 46/51 72 68/75

M12 86 80/87 125 117/128

M12x1.5 wheel screws 95 90/100

M16 210 194/214 310 285/314

M20 410 392/431 610 558/615

M24 710 675/743 1050 961/1059

Tightening torques for class 8.8 and 10.9 fasteners

All machine fastener torques should be regularly checked to the above table. In

particular, those for the flywheel blades, flywheel bearings, axle assembly, hitch,

road wheels and engine mounts.

Loading...

Loading...