P a g e | 19

Blade sharpening

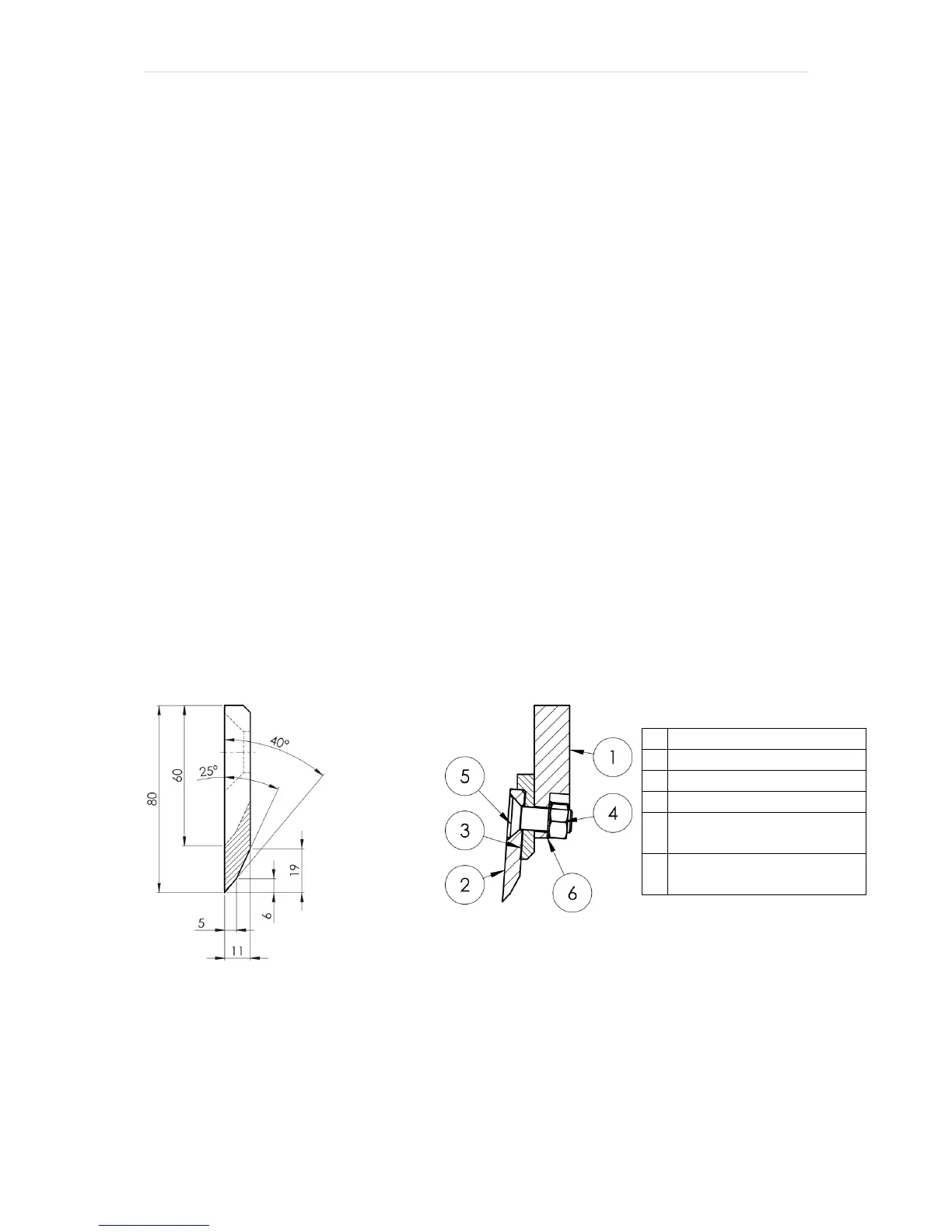

For optimum performance, blades need to be kept sharp. Minimum safe blade size

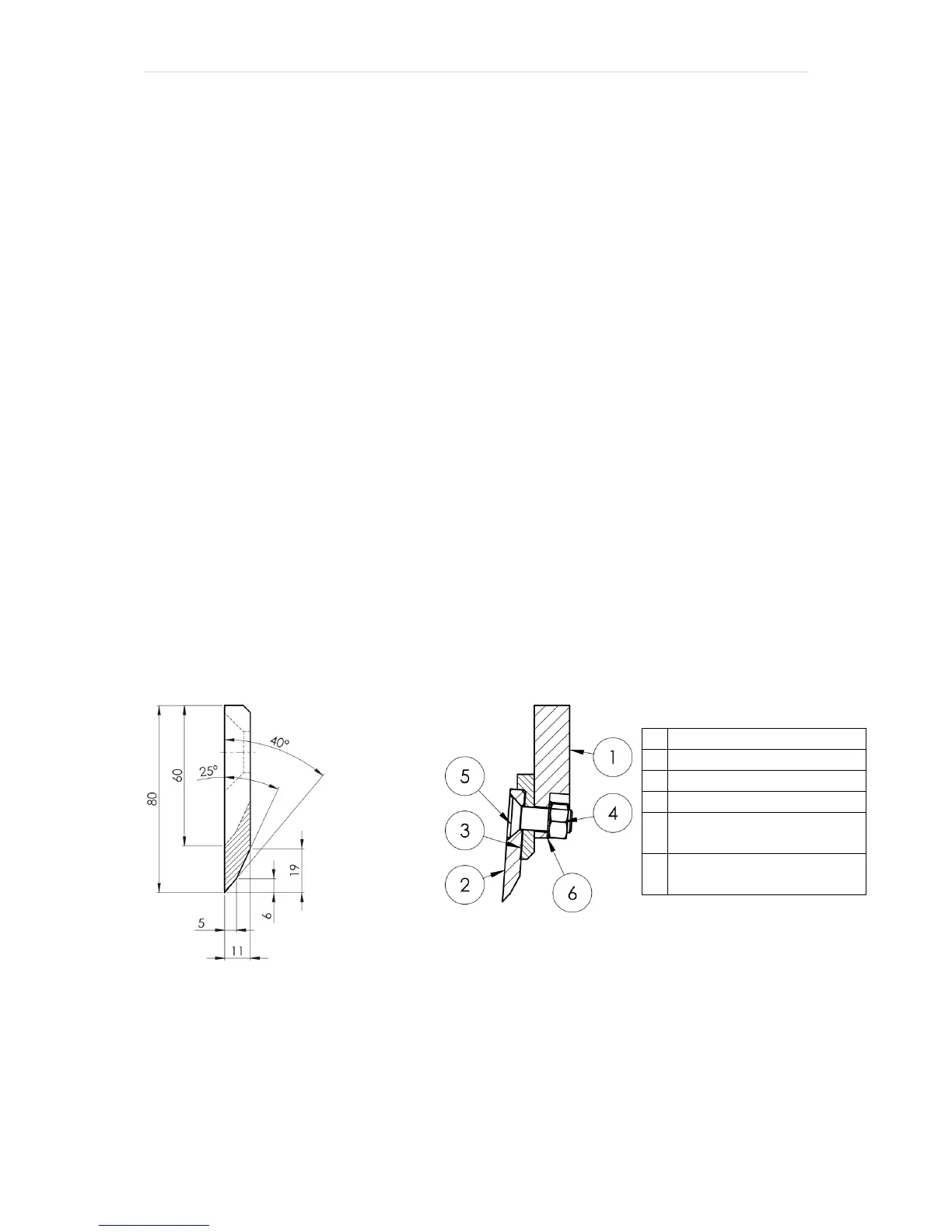

after sharpening as shown. After sharpening, the blade gap must be re-set by using

a blade shim as shown. Shims are available in thicknesses of 0.5, 1, 1.5, 2 & 2.5mm

as part number 12-03-093. On no occasion must more than one shim be fitted under

each blade at any time. A gap of 1mm must be set from the inner blade tip to anvil

after sharpening by placing an appropriate shim under the blade (also see flywheel

assembly). The outer blade tip is automatically set due to the anvil being set at an

angle to the blade. With 1mm at the inner blade tip, the outer blade tip should be

3mm from the anvil as shown.

The complete blade fastener set must be replaced every time blades are changed.

DO NOT Lubricate the Bolts when fitting.

Figure 6 Figure 7

Blade sharpening limit

80mm to 60mm

Loading...

Loading...