Daily Pretrip Inspection and

Maintenance

Complete the following inspection and maintenance

procedures to ensure that vehicle components are in

good working condition before each trip. A driver who

is familiar with the vehicle and drives it regularly can

perform the daily inspections, then add the weekly

and monthly post-trip inspections as scheduled.

If the driver does not operate the vehicle on a con-

sistent basis, all daily, weekly, and monthly inspec-

tion and maintenance procedures should be per-

formed before the trip.

IMPORTANT: The pre- and post-trip checklists,

inspections, and maintenance procedures de-

tailed in this chapter are not all-inclusive.

Refer to other component and body manufactur-

ers’ instructions for specific inspection and

maintenance instructions, as well as local, state,

and federal guidelines.

NOTE: If any system or component does not

pass this inspection, it must be corrected before

operating the vehicle. Whenever equipment re-

quires adjustment, replacement, and/or repair,

see the Century Class Trucks Workshop Manual

for procedures and specifications.

Suspension and Slack Adjuster

Inspection

Walk around the vehicle and visually inspect suspen-

sion and slack adjuster components.

1.

Inspect the following suspension components for

signs of structural damage, cracks, or wear.

•

springs

•

spring hangers

•

shocks

•

suspension arms

•

suspension brackets

•

axle seats

•

bushings

2.

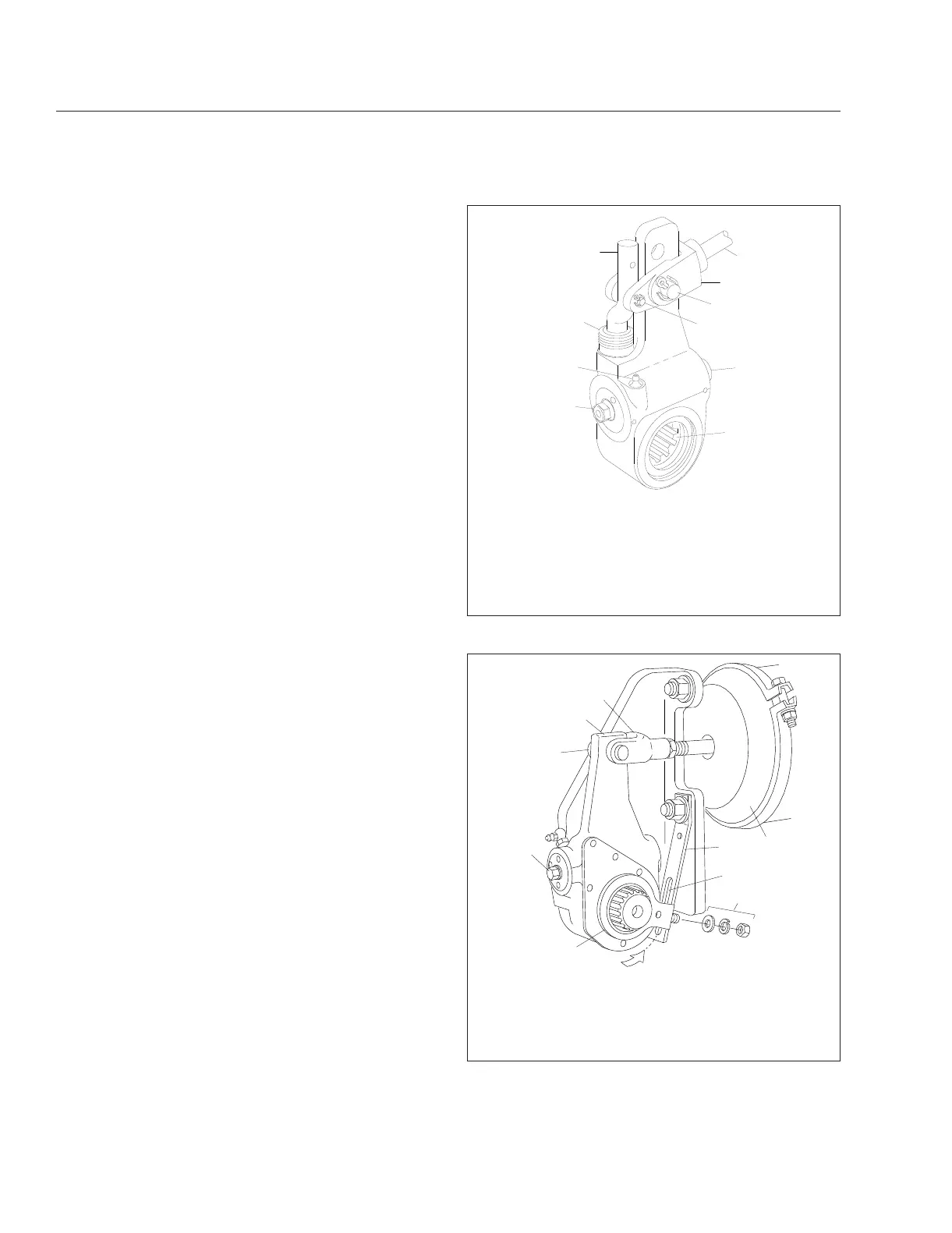

Inspect slack adjusters for signs of damage. See

Fig. 23.1, Fig. 23.2,orFig. 23.3.

f421398

06/17/2003

1

2

3

4

5

6

7

8

10

9

1. 7/16-inch Adjusting

Nut

2. Grease Fitting

3. Boot

4. Link

5. Brake Chamber Piston

Rod

6. Clevis

7. ½-inch Clevis Pin

8. 1/4-inch Clevis Pin

9. Grease Relief

Opening

10. Slack Adjuster Spline

Fig. 23.1, Gunite Automatic Slack Adjuster

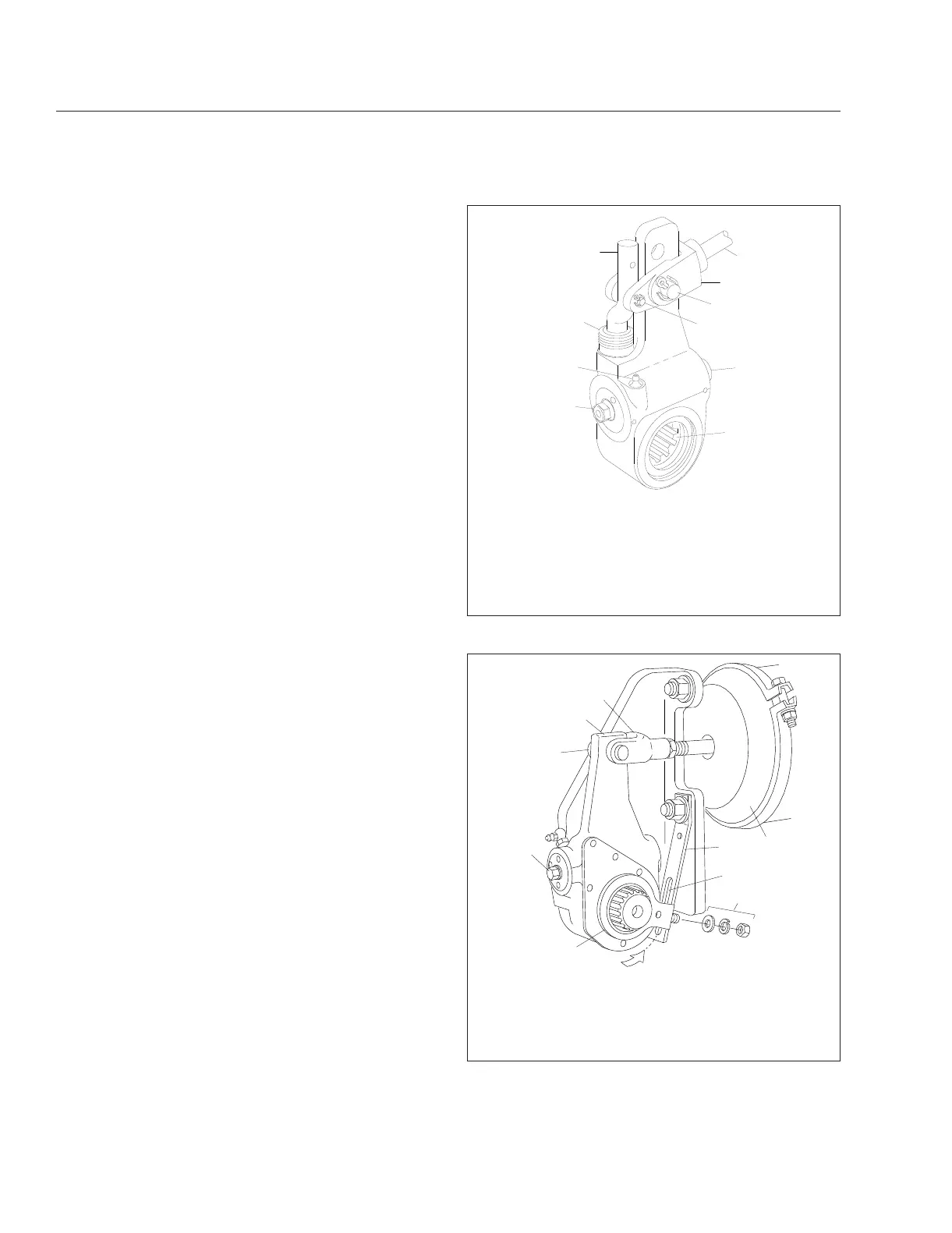

10/11/2005 f421397

1

2

3

4

5

6

7

8

9

A

1. Clevis

2. Slack Adjuster

3. Clevis Pin

4. Manual Adjusting Nut

5. Control Arm

6. Control-Arm Washers

and Nut

7. Anchor Strap Slot

8. Anchor Strap

9. Brake Chamber

Fig. 23.2, Haldex Automatic Slack Adjuster

Pre- and Post-Trip Inspections and Maintenance

23.1

Loading...

Loading...