11.1

Check for broken spring leaves, loose

U-bolts, cracks in the suspension

brackets, and loose fasteners in the spring

hangers and shackles.

11.2

Inspect the shock absorbers for loose fas-

teners and leaks.

11.3

Tighten all loose fasteners and have any

components replaced that are worn,

cracked, or otherwise damaged.

11.4

On vehicles with air suspensions, check

for leaks. Check air suspension compo-

nents for cuts and bulges.

12.

Clean the headlights, mirrors, windshield, side,

and rear windows with a long-handled or tele-

scoping window cleaning device and standard

cleaning solutions. Stand only on the ground, on

a stepladder, or an elevated walkway. The ve-

hicle entry/exit steps and handholds are not de-

signed for this purpose. The tires, fenders, en-

gine, and other under-hood components do not

have adequate gripping surfaces and handholds.

Check the condition of the windshield wiper arms

and blades.

Be sure the windshield wiper blades are ten-

sioned against the windshield.

Inspect the wiper blades for damage and deterio-

rated rubber.

Replace the wiper arms if the wiper blades are

not tensioned against the windshield.

Replace damaged or deteriorated wiper blades.

WARNING

When cleaning windshields and windows, always

stand on the ground or on a secure ladder or

platform. Use a long-handled window cleaner. Do

not use the cab steps, tires, fenders, fuel tanks,

engine, or under-hood components to access the

windshield or windows. Doing so could cause a

fall and result in an injury.

Replace wiper arms and blades when necessary

to maintain good visibility. Poor visibility could

interfere with the driver’s ability to control the

vehicle, possibly resulting in serious personal

injury or death.

13.

Check the oil- and air-pressure warning systems.

When the engine is started, oil- and air-pressure

warnings will come on until the oil and air pres-

sure rise above a preset minimum. After starting

the engine, make sure the oil- and air-pressure

warning systems are operating and that the

buzzer stops sounding when the preset minimum

is reached.

13.1

If the warning systems do not come on

when the ignition is turned on, have the

systems repaired.

13.2

If the air pressure in both systems is

above the preset minimum when the en-

gine is started, test the low air pressure

warning system by lowering the pressure

to below this range, or until the warning

system comes on.

NOTE: The air pressure in both the primary

and secondary air reservoir systems must

be above 65 psi (448 kPa) on most vehicles.

For vehicles with an optional Bendix dryer

reservoir module (DRM), the cut-out pres-

sure is 130 psi (896 kPa).

14.

Check the instrumentation control unit (ICU) for

fault codes.

During the ignition sequence, if an active fault is

detected in any device that is connected to the

datalink, the message display screen will show

the active fault codes, one after the other, until

11/30/95

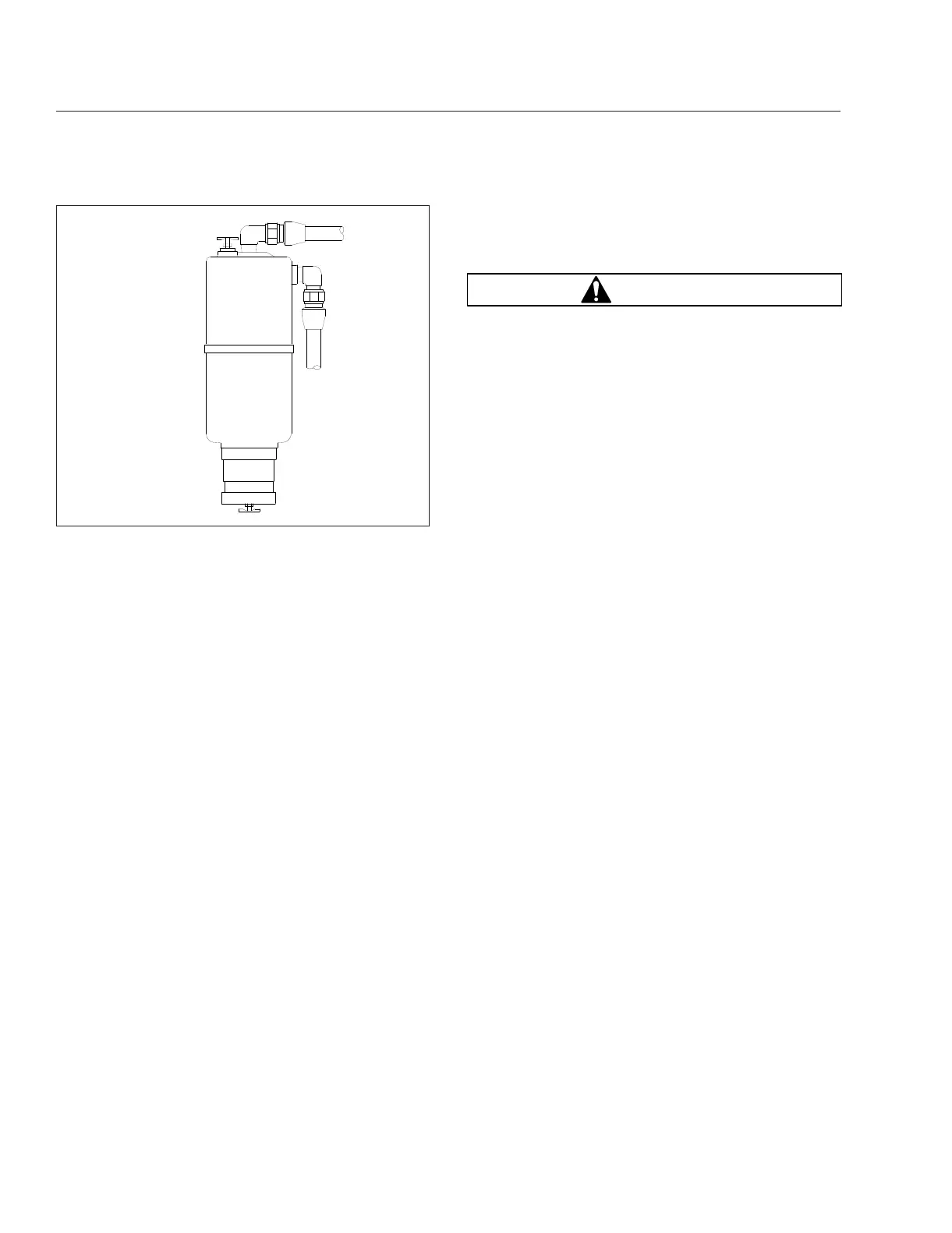

f470167

Fig. 15.6, Alliance Fuel/Water Separator

Pre- and Post-Trip Inspections and Maintenance

15.5

Loading...

Loading...