other serious injuries. Keep sparks and flames

away from propane. Do not smoke near propane

or when refueling the vehicle.

Propane is stored in the fuel tank under high

pressure. Never fill a leaking or damaged tank, as

this could result in serious injury. Have the ve-

hicle fuel tank(s) and fuel system inspected for

leaks by a trained technician annually.

Propane is a liquid under pressure and is stored in a

pressure vessel unlike a gasoline or diesel tank. A

propane tank must never be filled to more than 80%

of its actual capacity, to allow room for expansion.

80% is considered "full" for all propane tanks. When

the tank is filled to the correct 80% level, the fuel

gauge should read full.

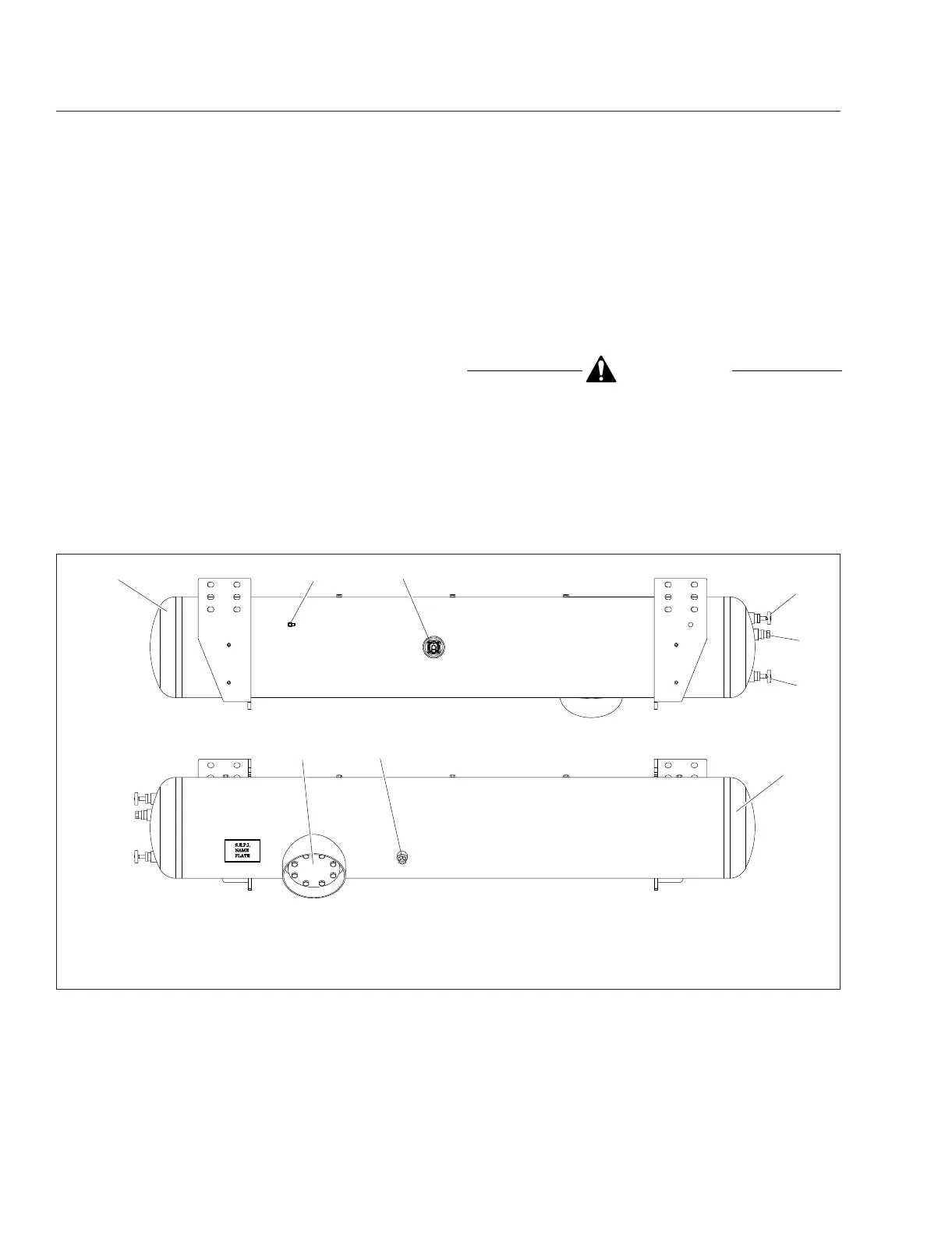

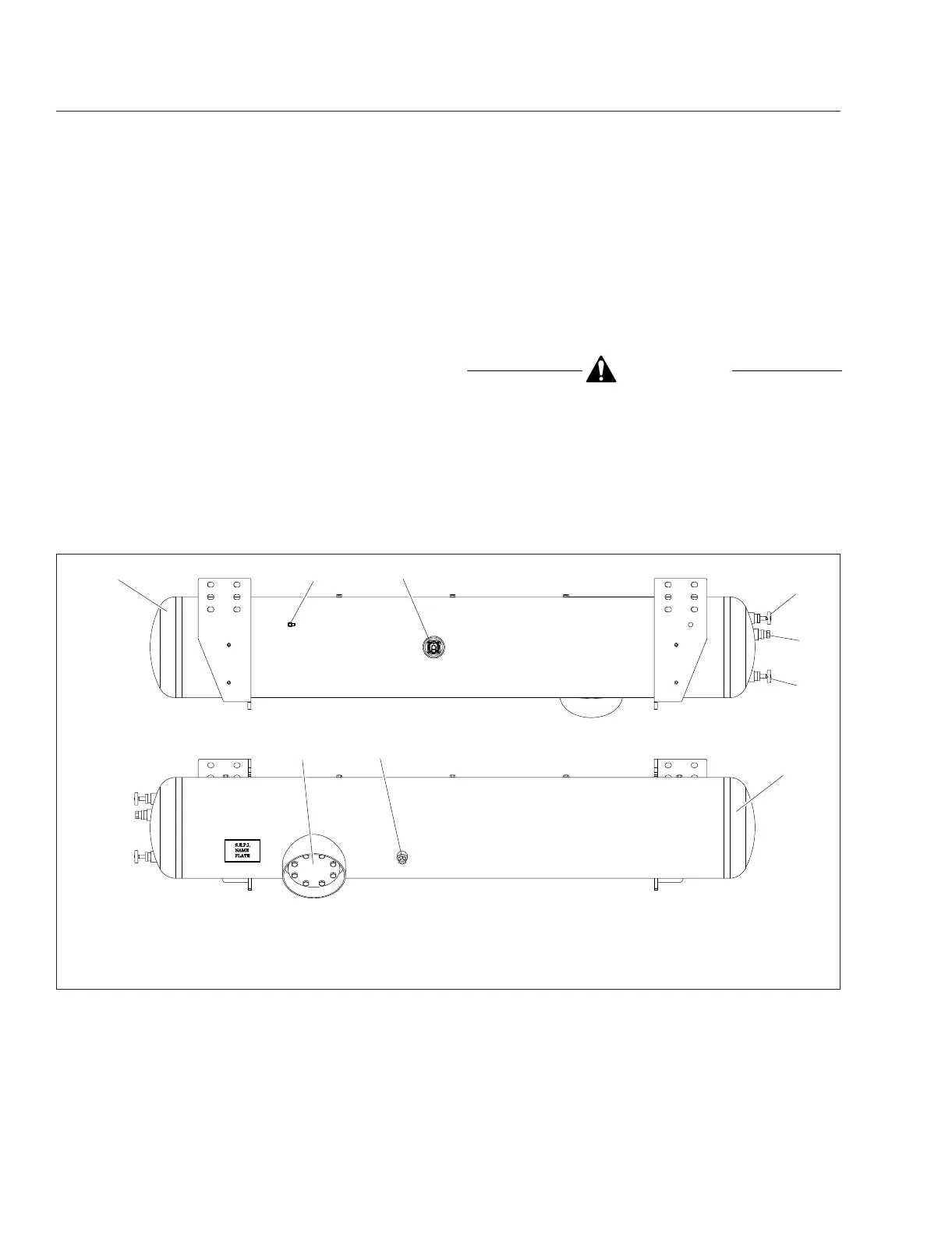

The following steps describe a typical refueling pro-

cedure. See

Fig. 19.3 for an example of the dual

propane tank system.

1.

Park the vehicle on level ground to ensure that

the tank is properly filled.

2.

Turn the vehicle ignition to OFF and set the park-

ing brake. Chock the tires if required.

3.

Ensure that there are no open flames or ignition

sources in the area.

4.

Turn the fuel tank cap counterclockwise and re-

move it.

5.

Inspect the fill valve O-ring, making certain the

O-ring is seated in the groove and is not dam-

aged or missing.

CAUTION

Never connect the propane fill nozzle to the tank

fill valve if the O-ring is damaged or missing, as

this could result in serious injury. Replace the

O-ring before connecting the propane fill nozzle.

6.

Connect the propane fill nozzle to the tank fill

valve.

7.

Rotate the propane fill valve nozzle clockwise

until it is firmly attached to the tank fill valve.

8.

Close the fill nozzle vent valve if so equipped.

10/30/2013 f470606

1

2

3

4

5

A

B

6

7

A. Front Side B. Back Side

1. Bleeder Valve

2. Fuel Level Gauge

3. Return Valve

4. Fill Valve

5. Service Valve

6. Pressure Relief Valve

7. Access Cover and Collar

Fig. 19.3, Propane Tank System

Propane Fuel System

19.5

Loading...

Loading...