070.610-IOM (JUL 21)

Page 17

RWF II Rotary Screw Compressor Units

Installation

Wire sizing

Control power supply wires should be sized one size larger

than required for amperage draw to reduce instantaneous

voltage dips caused by large loads such as heaters, con-

tactors, and solenoids. These sudden dips in voltage can

cause the electronic control panel, whether it is a micro-

processor, a computer, or a PLC, to malfunction momen-

tarily or cause a complete reset of the control system. If

the wire is loaded to its maximum capacity, the voltage

dips are much larger, and the potential of a malfunction is

very high. If the wire is sized one size larger than required,

the voltage dips are smaller than in a fully loaded sup-

ply wire and the potential for malfunction is much lower.

The NEC code book calls for specic wire sizes to be

used based on current draw. An example of this would be

to use #14 gauge wire for circuits up to 15 amps or #12

gauge wire for circuits of up to 20 amps. As a result, when

connecting the power feed circuit to an electronic control

panel, use #12 gauge wire for a maximum current draw of

15 amp and #10 wire for a maximum current draw of 20

amp. Use this rule of thumb to minimize voltage dips at

the electronic control panel.

Voltage source

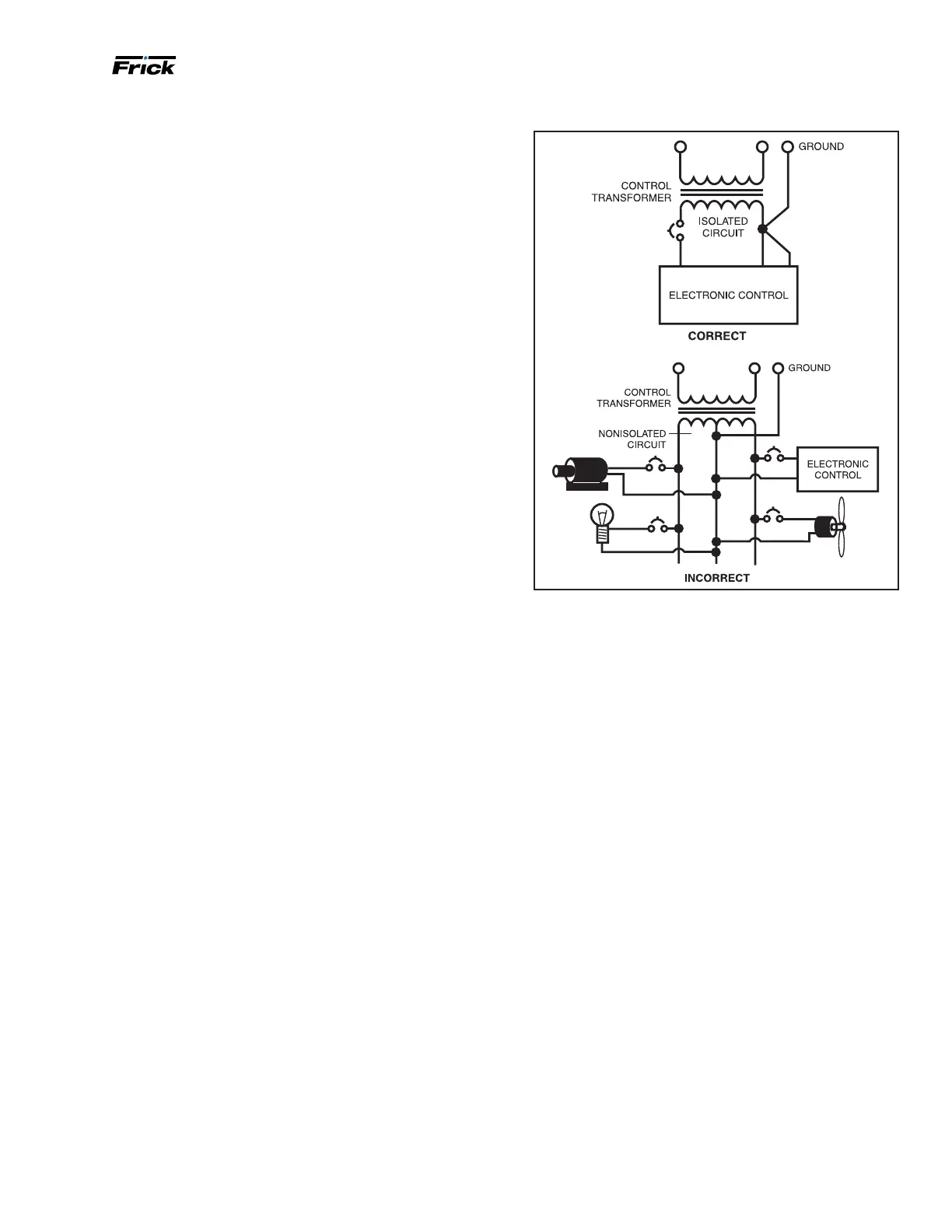

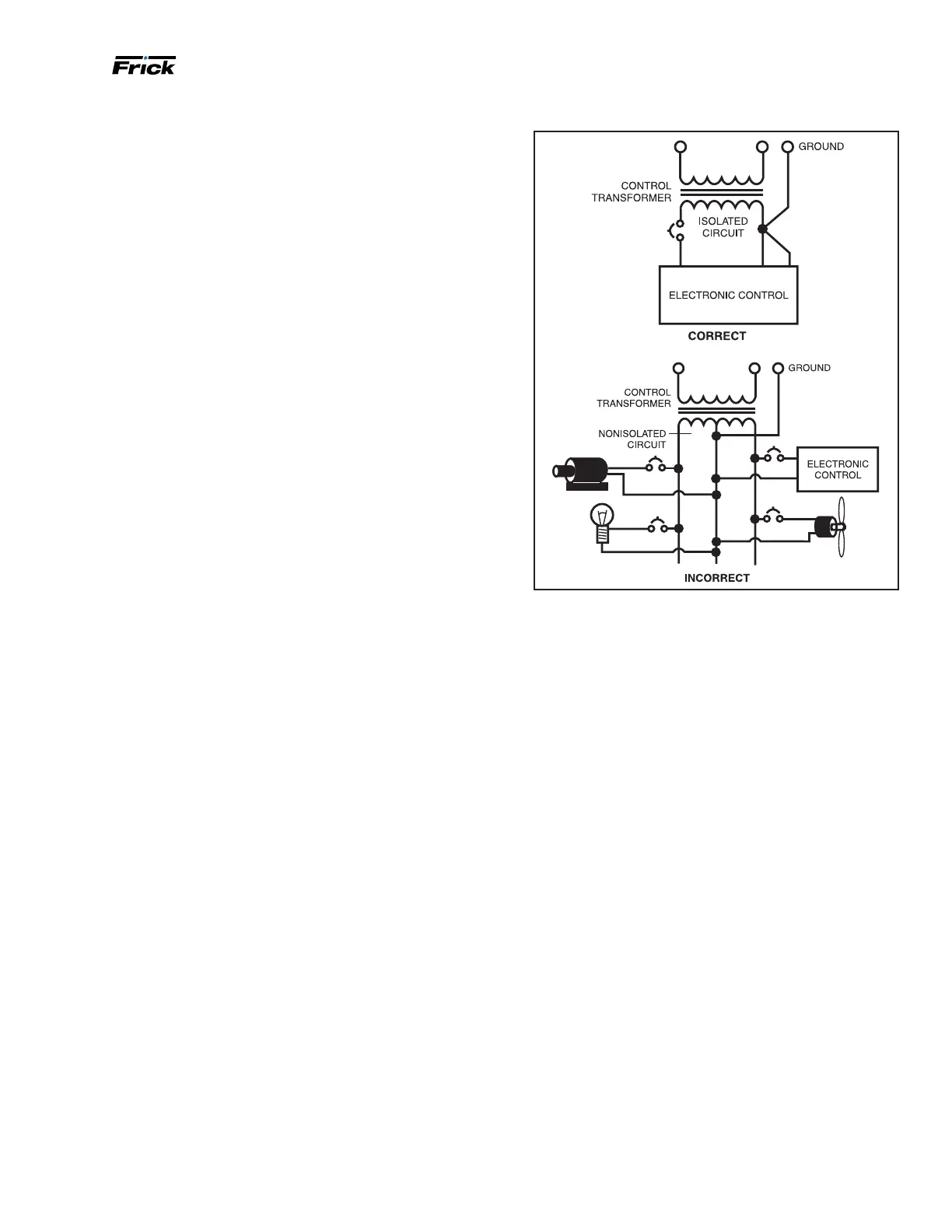

Selecting the voltage source is extremely important for

proper operation of electronic equipment in an industrial

environment. Standard procedure for electronic instru-

mentation is to provide a clean, isolated, separate-source

voltage in order to prevent EMI (from other equipment

in the plant) from interfering with the operation of the

electronic equipment. Connecting electronic equipment

to a breaker panel (also known as lighting panels or utility

panels) subjects the electronic equipment to noise gener-

ated by other devices connected to the breaker panel.

This noise is known as electromagnetic interference (EMI).

EMI ows on the wires that are common to a circuit. EMI

cannot travel easily through transformers and therefore

can be isolated from selected circuits. Use a control power

transformer of the proper VA rating, usually provided in

the compressor drive motor starter, to isolate the elec-

tronic control panel from other equipment in the plant that

generate EMI. See the following Figure.

Figure 20: Voltage source circuit to prevent EMI

Grounding

Grounding is the most important factor for successful

operation and is typically the most overlooked. The NEC

states that control equipment can be grounded by us-

ing the rigid conduit as a conductor. This worked for the

earlier relay systems, but it is in no way acceptable for

electronic control equipment. Conduit is made of steel and

is a poor conductor relative to an insulated stranded cop-

per wire. Electronic equipment reacts to very small cur-

rents and must have a proper ground in order to operate

properly; therefore, stranded copper grounds are required

for proper operation.

For proper operation, the control power ground circuit

must be a single continuous circuit of the proper sized

insulated stranded conductor, from the electronic control

panel to the plant supply transformer. See Figure 21. Driv-

ing a ground stake at the electronic control may also cause

additional problems since other equipment in the plant on

the same circuits may ground themselves to the ground

stake causing large ground ow at the electronic control

panel. Also, running multiple ground conductors into the

electronic control panel from various locations can create

multiple potentials resulting in ground loop currents. A

single ground wire (10 AWG or 8 AWG) from the electronic

control panel, that is bonded to the control power neutral

at the secondary side of the control power transformer

in the starter and then to the three-phase ground point,

yields the best results.

Loading...

Loading...