070.610-IOM (JUL 21)

Page 43

RWF II Rotary Screw Compressor Units

Maintenance

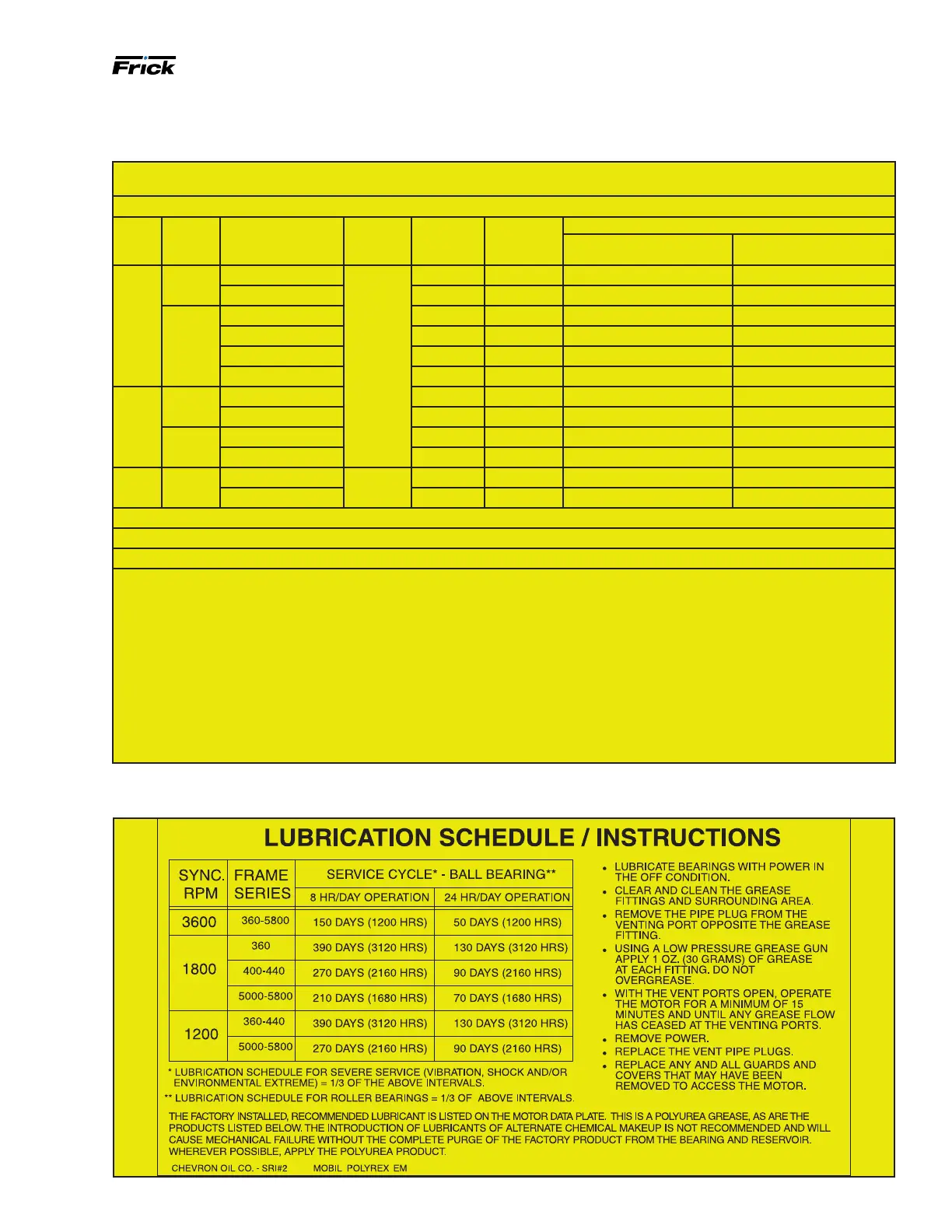

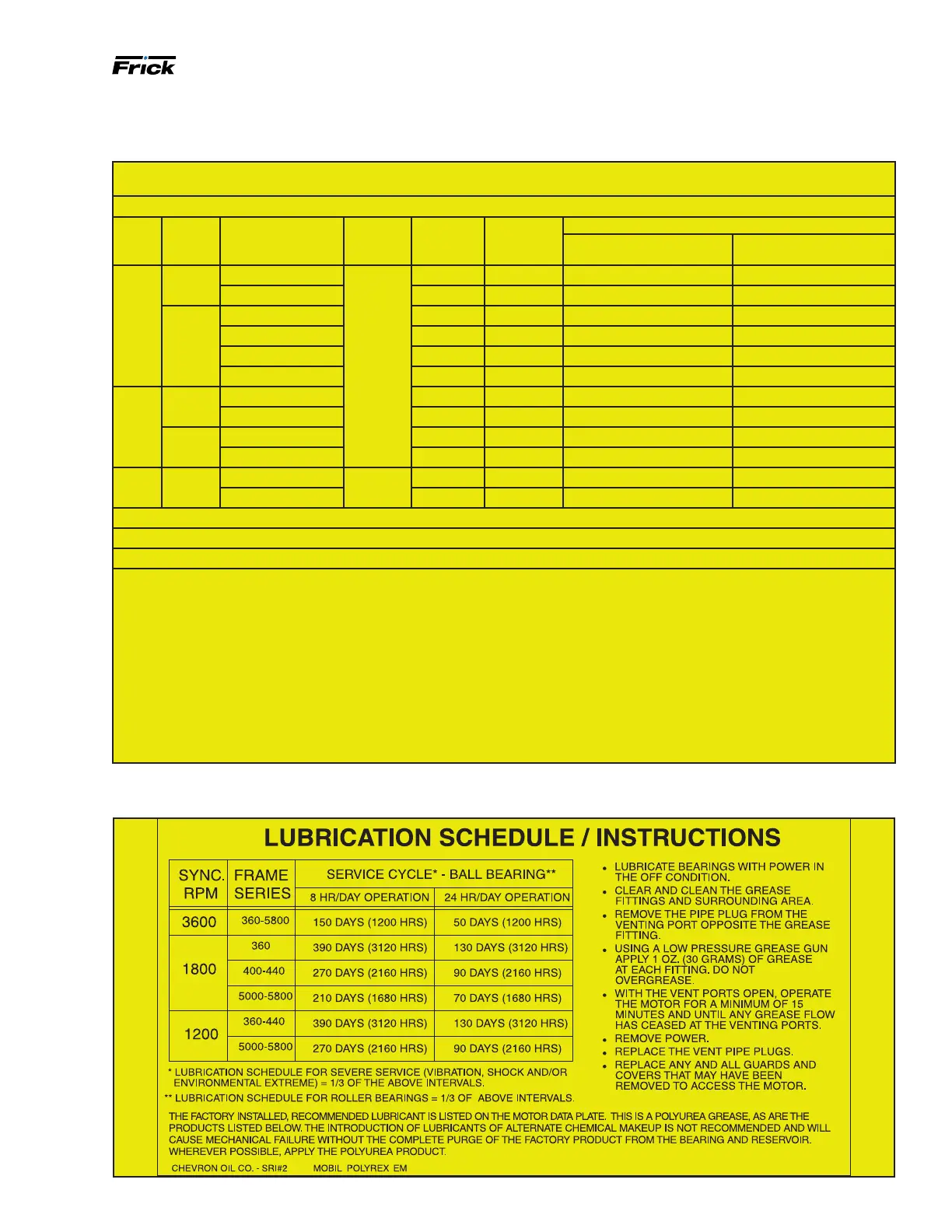

Table 15: Motor Lubrication schedule. For Marathon* Motors only. For other manufacturers, follow their schedule

Relubrication interval and instructions – WEG electric motor

Table 14:

Motor lubrication schedule. For WEG Electric Motors only. For other manufacturers, follow their schedule

WEG relubrication interval

W40 platform and ODP NEMA premium motors. Excludes W50 and W60 platforms

Drive

Sync.

Speed

(rpm)

Frame size Grease

Amount

(

g

)

Interval

(h)

Service cycle - ball bearings

8 hr/day operation 24 hr/day operation

SSS¹

1500 &

1800

284 - 326

Polyrex

EM

15 10800 1350 days (10,800 hr)

450 days (10,800 hr)

364 & 365 27 10800 1350 days (10,800 hr)

450 days (10,800 hr)

3600

284 - 326 15 10800 1350 days (10,800 hr)

450 days (10,800 hr)

364 – 5010 8 1100 135 days (1100 hr)

45 days (1100 hr)

L5010 15 1100 135 days (1100 hr)

45 days (1100 hr)

L5809 19 1100 135 days (1100 hr)

45 days (1100 hr)

VSD²

≤ 4200

284 - 326 15 8800 1100 days (8,800 hr)

366 days (8,800 hr)

364 - 5010 16 1100 135 days (1100 hr)

45 days (1100 hr)

≤ 3600

L5010 15 1100 135 days (1100 hr)

45 days (1100 hr)

L5809 19 1100 135 days (1100 hr)

45 days (1100 hr)

VSD

2,3

> 3600

L5010

Isoex

17 1100 135 days (1100 hr)

45 days (1100 hr)

L5809

21 1100 135 days (1100 hr)

45 days (1100 hr)

1: Solid State Starter / 2: Variable Speed Drive

3: L5010-L5809 frames intended for operation above 3600 rpm on VSD must be reviewed and approved by WEG

4: 364-L5809 frames: Bearing caps should be removed and cleaned of excess grease after 8800 hr

Procedure/warning:

- With the motor shutdown, inject approximately half of the total grease quantity to be used and operate the motor for approxi-

mately one (1) minute in full rotation speed.

- Shutdown the motor and inject the remaining grease. The injection of the entire amount of grease in an idle motor may cause

part of the lubricant to penetrate into the inner part of the motor through the internal sealing of the bearing cap.

-

The lubrication intervals specied consider an absolute temperature on the bearing of 149°F (65°C) the motor running at rated

speed, a motor mounted in horizontal position and greased with appropriate grease based on table above. Any variation of the

parameters listed above must be evaluated by WEG engineering.

- For each increment of 27°F (15°C) above the bearing temperature, the relubrication intervals given in the Table must be halved.

For special applications such as: high and low temperatures, aggressive environments, vertical mounting position, etc., please

contact WEG about the required amount of grease and the relubrication intervals.

Relubrication interval and instructions – Marathon

*Previously Regal, Ram, Schneider Electric

Loading...

Loading...