070.610-IOM (JUL 21)

Page 52

RWF II Rotary Screw Compressor Units

Maintenance

Shutdown due to improper oil

pressure (high stage and booster)

The compressor must not operate with incorrect oil

pressure.

1. Refer to Control setup - Oil setpoints display in pub-

lication 090.040-O.

Motor and bare compressor

replacement

Refer to publication 070.660-SM.

SAE straight thread o-ring ttings

assembly procedure

When performing maintenance or replacing the compres-

sor, the hydraulic tubing may need to be removed and

re-installed. The following procedure outlines the proper

installation of SAE straight thread ttings to SAE straight

thread ports.

The male and female ends of SAE straight thread O-ring

ports have UN/UNF straight threads. An elastomeric O-ring

is tted to the male end. On assembly, the O-ring is rmly

sandwiched between the angular sealing surface of the

female port and the shoulder of the male end. Sealing is

thus affected and maintained by the O-ring compression

which results from the clamping force generated by the

tightening action. The straight threads do not offer sealing

action; they provide the resistance (holding power) for

service pressure.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs, nicks

and scratches or any foreign material.

2. If the O-ring is not pre-installed to the tting on the

male end, install the proper size O-ring.

3. Lubricate the O-ring with a light coating of system oil

or petroleum jelly.

4. Screw the tting into the female port until the hex at

contacts the port face. Light wrenching may be necessary.

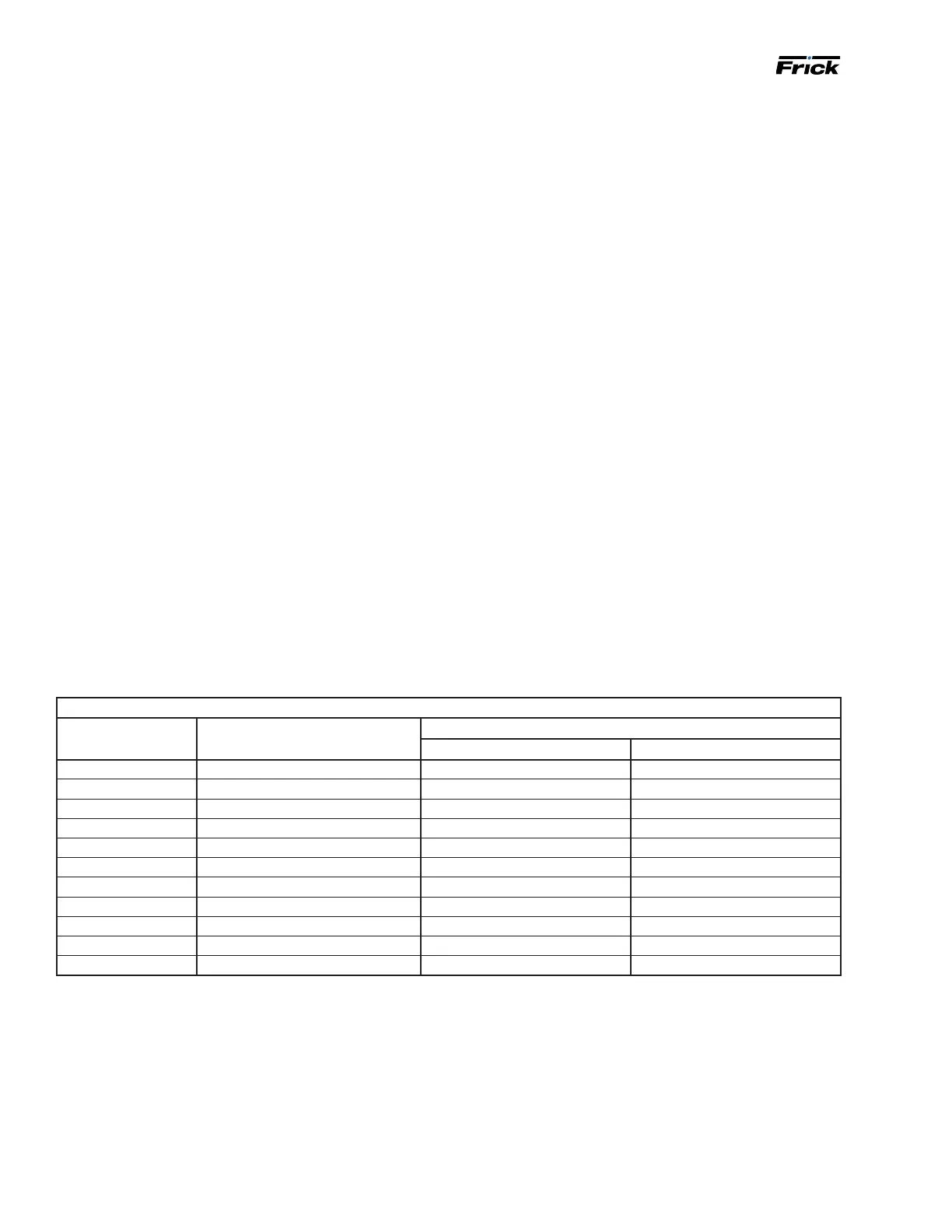

5. Tighten to the appropriate torque value shown in the following table.

Table 18: SAE port adjustable tting or plug torque

Straight and adjustable ttings or plugs (steel)

Fitting size SAE port thread size Assembly torque

in.-lb ft-lb

2 5/16 – 24 65 ± 5 5.5 ± 0.5

3 3/8 – 24 130 ± 10 11 ± 1.0

4 7/16 – 20 170 ± 10 14 ± 1.0

5 1/2 - 20 260 ± 15 22 ± 1.0

6 9/16 – 18 320 ± 20 27 ± 2.0

8 3/4 - 16 500 ± 25 42 ± 2.0

10 7/8 – 14 720 ± 30 60 ± 2.5

12 1

1

⁄16 – 12 960 ± 50 80 ± 5.0

16 1

5

⁄16 – 12 1380 ± 75 115 ± 6.0

20 1

5

⁄8 – 12 2700± 150 225 ± 12.0

24 1

7

⁄8 - 12 3000 ± 160 250 ± 12.0

Loading...

Loading...