070.610-IOM (JUL 21)

Page 42

RWF II Rotary Screw Compressor Units

Maintenance

Oil quality and analysis

High quality refrigeration oil is necessary to ensure

compres sor longevity and reliability. Oil quality will rapidly

deteriorate in refrig eration systems containing moisture

and air or other contaminants. In order to ensure the qual-

ity of the refrigera tion oil in the com pressor unit.

WARNING

Do not mix oils of different brands, manufacturers, or

types. Mixing of oils may cause excessive oil foaming,

nuisance oil level cutouts, oil pressure loss, gas or oil

leakage and catastrophic compressor failure.

NOTICE

The Frick oil charge shipped with the unit is the best

suited lubricant for the conditions specied at the

time of purchase. If there is any doubt due to the re-

frigerant, operating pressures, or temperatures, refer

to Frick Oil publication 160.802-SPC for guidance.

Only use Frick oil lter elements or warranty claim

may be denied.

1. Participate in a regular, periodic oil analysis program

to maintain oil and system integrity. Oil analysis kit part

number: 333Q0001853.

2. Oil samples for analysis should be taken after the oil

lter. A 1/4 in. purge valve is provided in the oil lter can-

ister head.

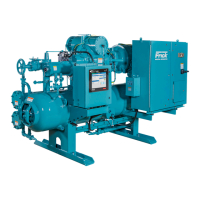

Figure 46: Oil sampling valve

Locknut

Locknut

Valve Cap

& Spout

Valve Cap

& Spout

DO NOT

UNTHREAD

VALVE!

Oil sampling procedure

WARNING

Exercise extreme caution in the vicinity of operating

equipment. Skin contact with lube oil or inhalation

of vapors can cause serious injury or death, consider

gloves and eye protection.

Sample hot, active uid while the equipment is operating.

Sample after 30 min of compressor operation.

1. Unthread the oil sampling valve cap and locknut

(see Figure 46).

CAUTION

Do not unthread the valve from the lter housing or

piping or uncontrolled release of oil will result.

2. Unthread the bottle cap and carefully position under

the oil sampling valve spout. Place the spout inside the

bottle.

3. Push the oil sampling valve to open and release to

close (spring actuated, see Figure 46, inset). Fill the bottle

3/4 full.

4. Retighten bottle cap, sampling valve cap and locknut.

Please note that the locknut prevents accidental release of

oil.

5. Record all necessary sample data and identication on

forms and labels and send promptly to the lab for results.

Operating log

The use of an operating log as included in this manual (see

Table of Contents) permits thorough analysis of the opera-

tion of a refrigeration system by those responsible for its

maintenance and servicing. Continual recording of gauge

pressures, temperatures, and other pertinent information,

enables the observer and serviceman to be constantly

familiar with the operation of the system and to recognize

immediately any deviations from normal operating condi-

tions. It is recommended that readings be taken at least

every four hours.

Motor bearings

Follow the motor manufacturer’s maintenance

recommenda tions for lubrication. See Table 14 and Table

15 for WEG and Marathon.

WARNING

Make sure the motor bearings are properly lubricated

before start-up as required by the motor manuf ac turer.

Loading...

Loading...