070.610-IOM (JUL 21)

Page 31

RWF II Rotary Screw Compressor Units

Operation

Suction check valve power assist kit

Low temperature booster compressor applications require

hot gas to assist the suction check valve closure for RWF II

models 496, 676, 856, and 1080. This is accomplished by

using the high pressure discharge gas from the high pres-

sure side of the system (power assist kit).

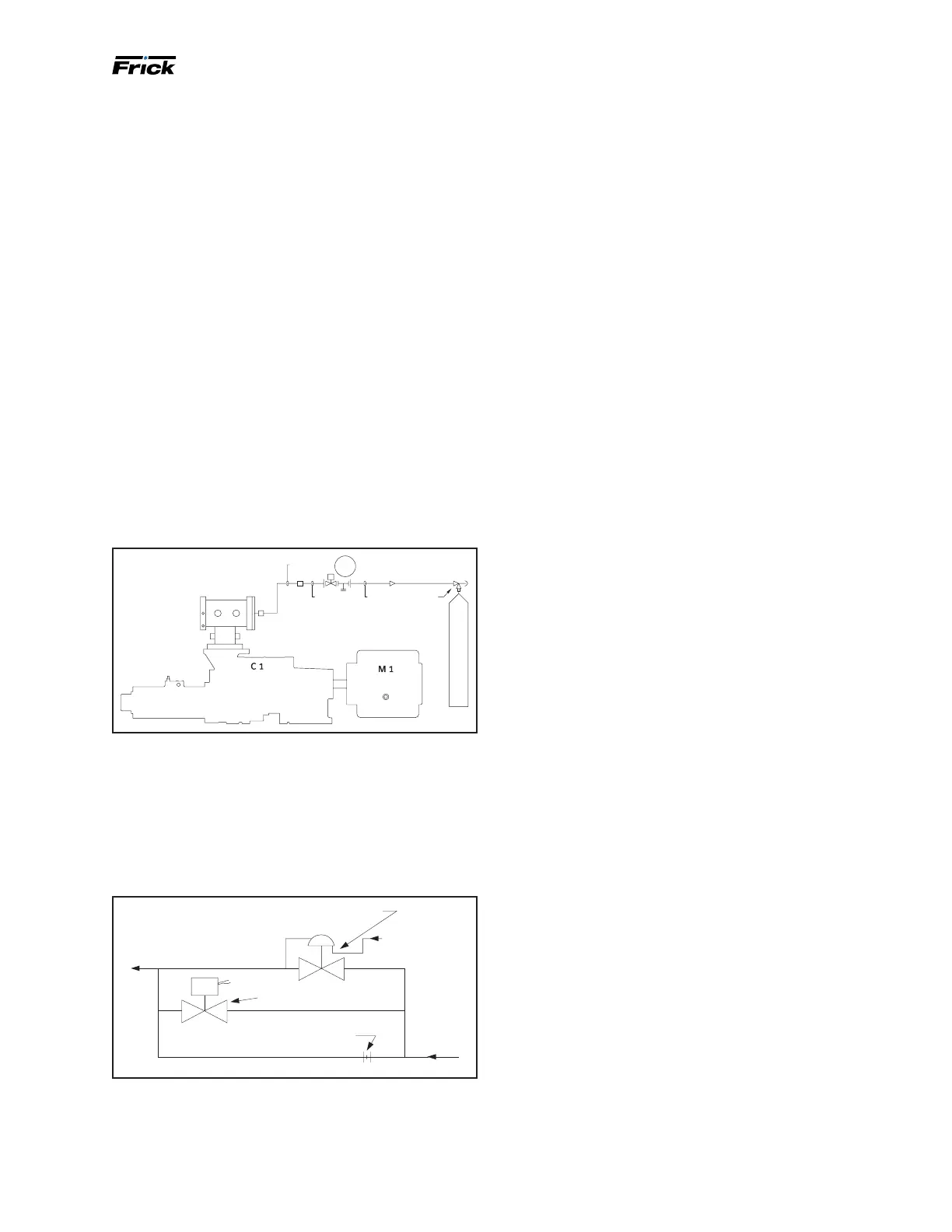

The power assist kit (see Figure 37) is factory installed

with the discharge gas pressure being supplied from the

high stage discharge gas. Running piping, rather than tub-

ing, to supply high pressure gas to the unit is recommend-

ed. The piping should be at least 3/4 in. in diameter, and

should be insulated and heat traced to prevent internal

condensation.

The power assist kit consists of a strainer, mounted and

wired solenoid valve, timer, and metering valve. The timer

limits the high pressure gas feed to the suction check

valve to thirty seconds via the solenoid valve. This is suf-

cient time to warm the suction check valve piston and

provide proper operation. The metering valve is provided

for use as a service valve and to allow discharge gas ow

regulation to prevent excessive force and resulting closure

"hammering". The valve should be adjusted accordingly to

prevent such an occurrence.

Figure 37: Power assist kit

POWER ASSIST TO BE CONNECTED TO

CONN IN CENTER OF MV END PLATE

HIGH PRESSURE GAS FROM HIG

H

E

3/8 OD

1/21/2

3/8

STR-4

S

YY

7

Balance piston pressure regulator

A Balance Piston Pressure Regulator may be required on

Models 496 to 1080 to reduce the extended overbalance

from the thrust balance piston at part load.

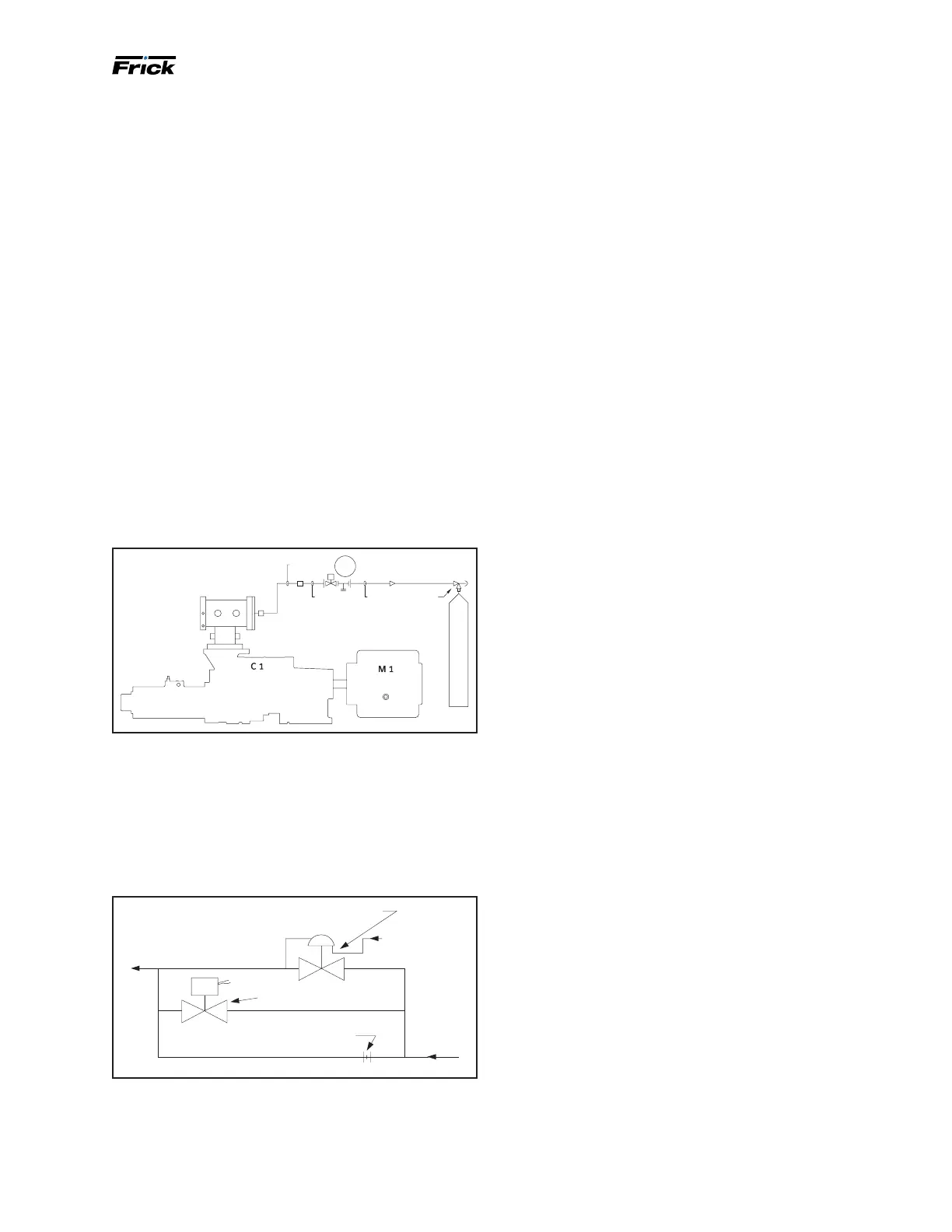

Figure 38 shows the three additions described below ar-

ranged in parallel.

Figure 38: High-stage SB-2 oil supply line diagram

534B0325H01 1/8" RESTRICTION ORIFICE

951A0007H01 (OR H03)

SOLENOID VALV E

TO SB-2

COMPRESSOR

PORT

954A0014H01 PRESSURE-REGULAT INGVALVE (A4ALE)

FROM

COMPRESSOR

DISCHARGE OR

OIL MANIFOLD

BLPSPREG

FROM OIL

MANIFOLD

Pressure-regulating valve: Discharge pressure determines

compressor thrust balance. The proper setting for the

pressure-regulating valve is 50 psi (±15) below discharge

pressure when slide valve is less than 65%.

Solenoid valve: Energizing, or opening, the solenoid valve

pressurizes the balance piston with full oil pressure from

the oil manifold, bypassing the A4ALE Pressure Regulating

Valve. De-energizing, or closing, the solenoid valve pres-

surizes the balance piston with oil pressure regulated by

the A4ALE Pressure Regulating Valve.

Signals from the control panel operate the solenoid valve

(output module 12 on micro panel). The solenoid valve

should open when the slide valve position is 70% or

greater, and close when the slide valve position is 65% or

less.

Orice: The orice ensures oil supply to the inlet end

bearings during upset conditions such as start-up.

Initial start-up

Initial start-up must be performed under the super vision of

a Johnson Controls-Frick authorized start-up representa-

tive to prevent voiding the compressor warranty. Before

the start-up, complete the prestart check. See the RWF II

Compressor prestart checklist in the Forms section.

Initial start-up procedure

Having performed the checkpoints on the prestart check

list (see Forms), the compressor unit is ready for start-up.

It is impor tant that an adequate refrigerant load be avail-

able to load test the unit at normal operating conditions.

The following points should be kept in mind during initial

start-up.

1. It is imperative that during the initial start-up of the

package that the hand expansion valve on the main oil

injection line is fully open to ensure adequate oil ow.

There is still an orice installed in the compressor to con-

trol maximum oil ow. At initial start-up of the package

the hand expansion valve must be fully open. After initial

start-up of the package the hand expansion valve should

be adjusted. There are two methods of determining the

correct adjustment of this valve.

The best method to determine target discharge tempera-

ture is to run CoolWare™ with the operating conditions

of the compressor. The program will give you a theoreti-

cal discharge temperature of the compressor. Once this

temperature is known, you may adjust the hand expansion

valve. The ideal discharge temperature is within 5°F + or –

of the theoretical discharge temperature. Adjust the valve

to achieve the theoretical discharge temperature. If you

do not have access to CoolWare™, 180°F is a good target

discharge temperature for a high stage ammonia compres-

sor. Booster applications and compressors using HFC and

HCFC refrigerants may run cooler. Compressors with high

discharge pressure may run hotter.

The rst method is used for compressors with external oil

cooling (thermosyphon, water cooled, and glycol cooled).

Before the initial startup of the compressor close the hand

expansion valve completely. Open the valve back up and

count the turns that it takes to fully open the valve. After

the initial startup close the valve to achieve approximately

180°F discharge temperature or the theoretical tempera-

ture from CoolWare. Do not fully close the valve at any

time while the compressor is running.

Loading...

Loading...