070.650-IOM (JUL 19)

Page 26

SGC/SGX ROTARY SCREW COMPRESSOR

INSTALLATION

Once the compressor is rigged into place, its feet must be

shimmed to level it. There must be absolutely no stresses

introduced into the compressor body due to bolting of the

feetandanges.

The compressor motor mount is not designed to carry the

unsupported weight of the motor. The full motor weight

must be supported using the motor lifting point during the

motor installation process. After the necessary bracket

to support the motor have been welded into place on the

package and the rear motor feet and the motor mount

have been bolted into place, the weight of the motor can

rest on the support bracket and the motor mount.

In any screw compressor installation, support suction and

discharge lines in pipe hangers, preferably within 2 ft of

vertical pipe run, so that the lines won’t move if discon-

nected from the compressor. See Table 4 for Allowable

Flange Loads.

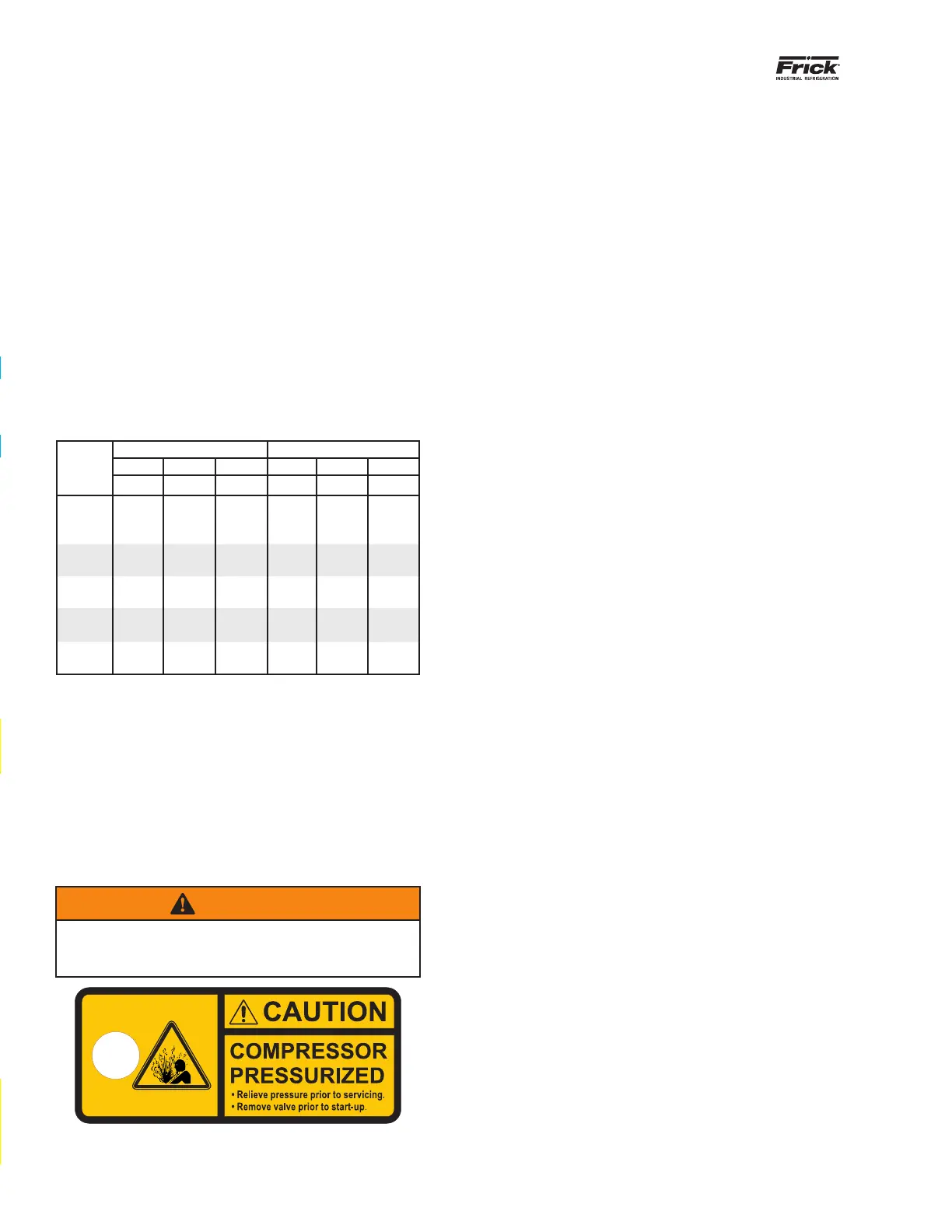

Table 4: Allowable ange loads

Noz. Moments (ft-lbf) Load (lbf)

size Axial Vert. Lat. Axial Vert. Lat.

NPS M

r

M

c

M

l

P V

c

V

l

1 25 25 25 50 50 50

1.25 25 25 25 50 50 50

1.5 50 40 40 100 75 75

2 100 70 70 150 125 125

3 250 175 175 225 250 250

4 400 200 200 300 400 400

5 425 400 400 400 450 450

6 1,000 750 750 650 650 650

8 1,500 1,000 1,000 1,500 900 900

10 1,500 1,200 1,200 1,500 1,200 1,200

14 2,000 1,800 1,800 1,700 2,000 2,000

CUSTOMER CONNECTIONS

Asaminimum,connecttothelocationsspeciedinFig-

ures 3 to 9, 26, and 27 in addition to suction and discharge.

Other connections are available for instrumentation, oil

return, and service as noted on the Dimensional Outline

drawing. The electrical connections for the slide stop and

the slide valve transmitters and the solenoid valve coils

must connect to your control system.

OIL SYSTEM REQUIREMENTS

Warning

Access valves in brass material must be removed and

the holes lled with steel plugs when package is as-

sembled.

Figure 15: Caution/Identication tag on access valve

The oil system must provide oil to the compressor within

limitation on:

• Oil selection

• Oil pressure

• Oil temperature

• Oil cleanliness

OIL SELECTION

The oil must be suitable for the application, refrigerant,

and operation condition. Compressor bearings require

a minimum viscosity based on size and speed (rpm). A

maximum viscosity of 100 cSt must not be exited.

FRICK compressor oils are recommended — refer to

160.802-SPC. Coolware provides FRICK oil properties and

information on viscosity requirements for a given com-

pressor selection.

OIL PRESSURE

Design the complete oil system so that the pressure does

notdropmorethan15psiwithacleanoillterelement.

This is critical for the proper function of the balance piston

and to ensure the life of the axial bearings. For low pres-

sure and low pressure differential operation, an oil pump

mustbebuilt-intoprovidesufcientoilpressure.

The control system needs to be capable of checking the

oil pressure and compare to both suction and discharge

pressures. In general, oil pressure must be a minimum of

1.5 times suction pressure plus 15 psi, and greater than

the discharge pressure minus 25 psi. For applications with

economizer and/or sideloading, the oil pressure must addi-

tionally be more than 15 psi above the pressure at the side

port when in operation.

Advanced control systems like the FRICK Quantum HD

monitor the oil pressure in many more ways in order to

keep the compressor running beyond these basic limits.

This advanced control keeps the compressor running

safely in partial load conditions.

See Oil Pump section for additional information.

BALANCE PISTON OIL REQUIREMENTS AND REGULA-

TIONS

All SG compressors have a balance piston on the male

rotor inlet end (see Figure 13). Oil is fed to the balance

piston to counteract a portion of the force of gas pressure.

For models using 193 mm to 283 mm rotors, the balance

piston oil feed is internal using the common oil connection

throughtheSB-3port(standardconguration).Aseparate

congurationisavailableforhighpressureoperation.On

355 and 408 compressors the oil is fed separately through

the SB-2 port (see Figure 14). Generally, 355 mm balance

piston regulation must meet requirements of CES 6605.

408 mm balance piston pressure must meet requirements

ofCES6607.Keeptheoilpressurewithinthespecied

range on all compressors.

added text " (standard

conguration).Aseparate

congurationisavailable"

for high pressure opera-

tion.

Loading...

Loading...