070.650-IOM (JUL 19)

Page 40

SGC/SGX ROTARY SCREW COMPRESSOR

MAINTENANCE

TROUBLESHOOTING GUIDE (CONTINUED)

CAPACITY LINEAR TRANSMITTER REPLACEMENT -

SLIDE VALVE

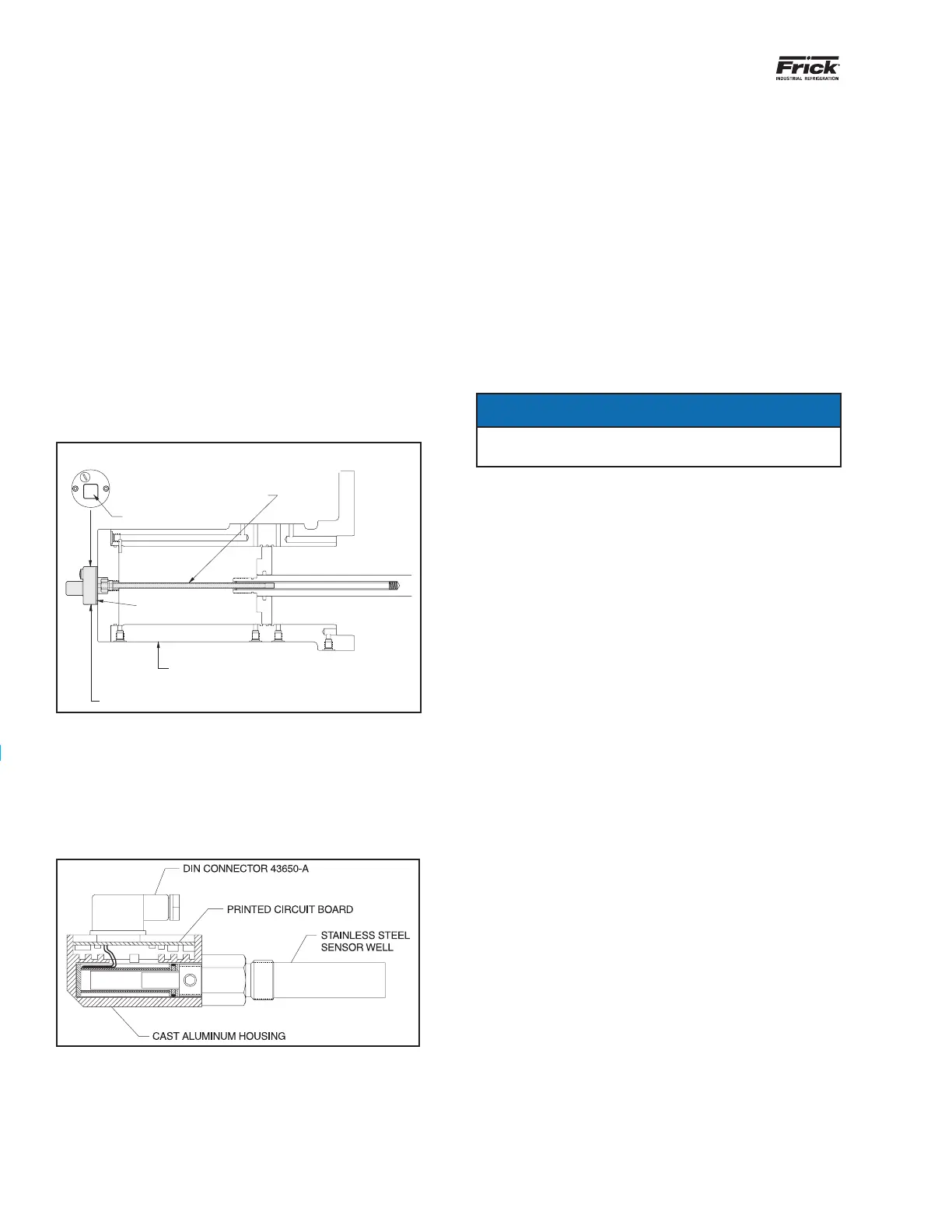

The Capacity Linear Transmitter is located on the end of the

compressor cylinder (see Figure 29). The linear transmitter

with hermetic enclosure is based on the inductive measuring

principle. It features removable electronics (from the sensor

well) eliminating the need to evacuate the compressor for

replacement. This type of transmitter is dedicated to capacity

control and is not adjustable.

1. Shut off control power.

2. Remove DIN connector plug from transmitter.

3. Loosen cap screws.

4. Remove transmitter unit.

5. Install new transmitter unit.

6. Tighten cap screws.

7. Apply DIN connector plug to transmitter.

8. Turn on control power.

ENDVIEW

DIN CONNECTOR

STAINLESS STEEL WELL

HEAT ISOLATOR

CAST ALUMINUM HOUSING

COMPRESSOR UNLOAD CYLINDER

SHADED AREA SHOWS

CAPACITY LINEAR TRANSMITTER

Figure 29: Capacity linear transmitter

VOLUMIZER

®

TRANSMITTER REPLACEMENT - SLIDE

STOP

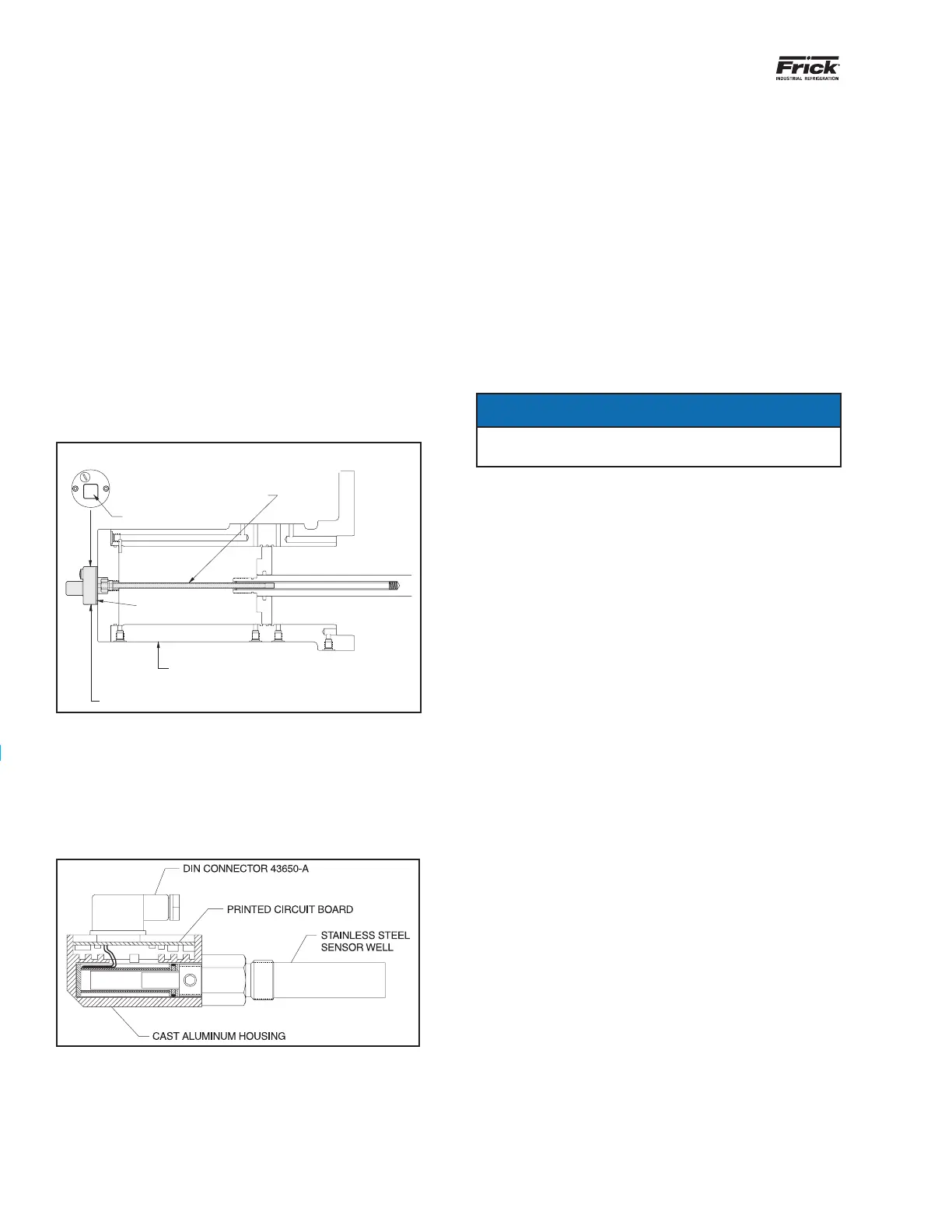

The VOLUMIZER

®

Transmitter is located on the right side

of the compressor (facing shaft) at the inlet end (see

Figure 30).

Figure 30: Volumizer

®

transmitter

The linear transmitter, with hermetic enclosure is based

on the inductive measuring principle. It features removable

electronics (from the sensor well) eliminating the need to

evacuate the compressor for replacement. This type of

transmitter is dedicated to volume ratio control and has no

user adjustments.

1. Shut off control power.

2. Remove DIN connector plug from transmitter.

3. Loosen setscrews.

4. Remove transmitter unit.

5. Install new transmitter unit.

6. Tighten setscrews.

7. Apply DIN connector plug to transmitter.

8. Turn on control power.

Notice

For calibration of the Volumizer

®

unit, refer to the Analog

Calibration instructions in publication 090.040-O.

BARE COMPRESSOR REPLACEMENT

The following procedure is required only when replacing a

barecompressorintheeldthathasnomotortunnel:

1. Verify that the starter is locked out.

2. Remove all tubing, piping, and wiring that is connected

to the compressor.

3. Disconnect the coupling from the motor shaft.

4. While supporting the motor and compressor assembly

with a crane, remove the bolts at the compressor feet.

5. Thoroughly clean the compressor feet and mounting

padsofburrsandotherforeignmattertoensurerm

seating of the compressor.

6. Thoroughly clean the new compressor and remove all

cover plates and protection.

7. Install new gaskets and sealing in all connections.

8. Set the new compressor in place and shim feet where

required.

9. Reattach the drive coupling.

10. Check the shaft alignment.

11. Complete tubing, piping, and wiring.

Note: Refer to 070.660-SM - Bare Rotary Screw Compres-

sor Replacement when a motor tunnel is installed.

SHUTDOWN DUE TO IMPROPER OIL PRESSURE

(HIGH STAGE AND BOOSTER)

The compressor must not operate with incorrect oil pressure.

1. Refer to CONTROL SETUP

Loading...

Loading...