070.650-IOM (JUL 19)

Page 29

SGC/SGX ROTARY SCREW COMPRESSOR

INSTALLATION

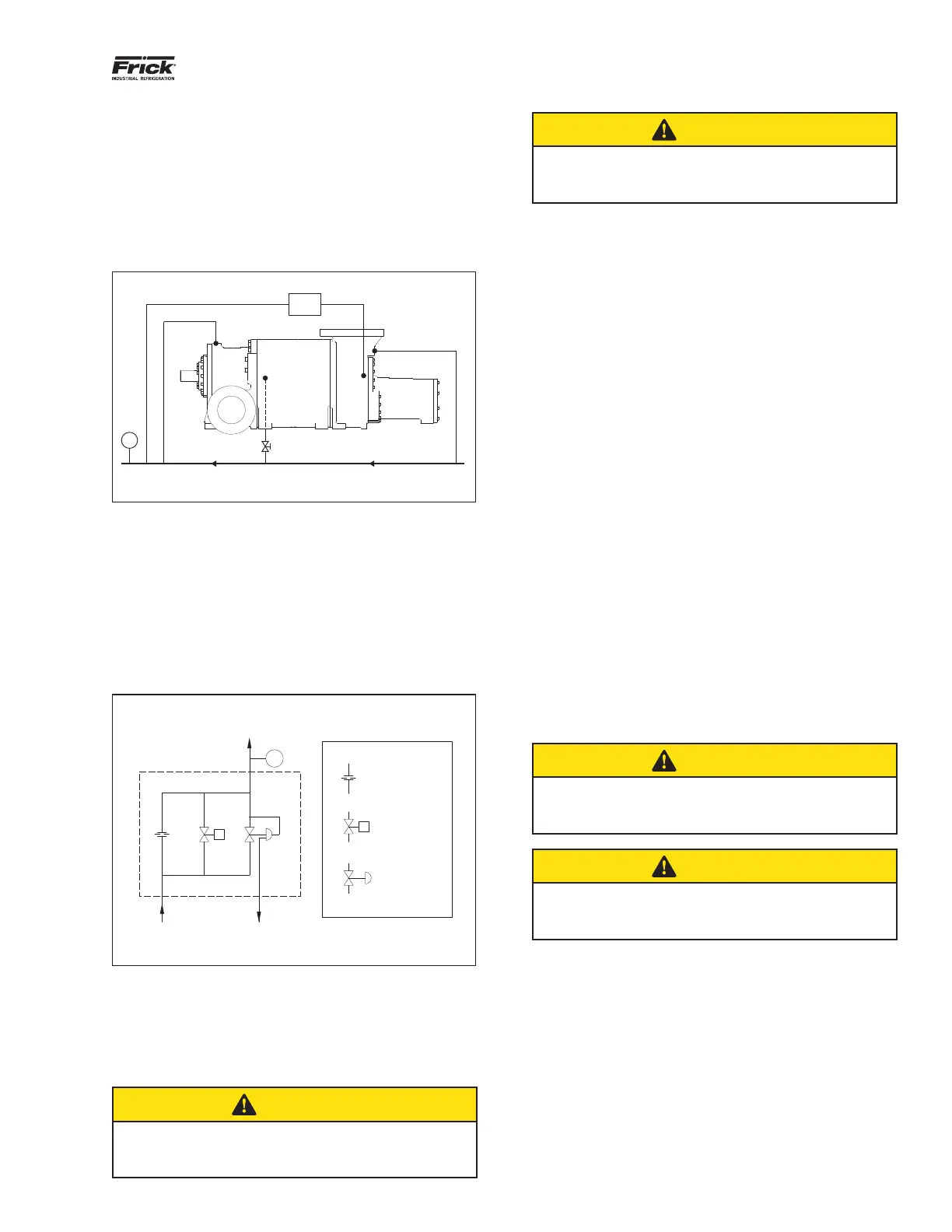

In most cases, SGCH/SGXH 355 and 408 compressor mod-

els require an active regulation of the oil pressure to SB-2.

Balance Piston Regulation (BPR) is needed because the gas

force varies with the position of the slide valve. A low slide

valve position could reduce the load below the minimum

required for the axial bearings. Figure 19 shows a piping and

instrumentation diagram of a compressor with BPR. There

areseveralBPRcongurationsavailableanditisimportant

to select one that works well for the application.

SB3

Each line connects to the main header

1.5”

1” Min.

SM1

SB2

SB4

P

OIL

BPR

Figure 19: SGXH compressor (355/408) with BPR

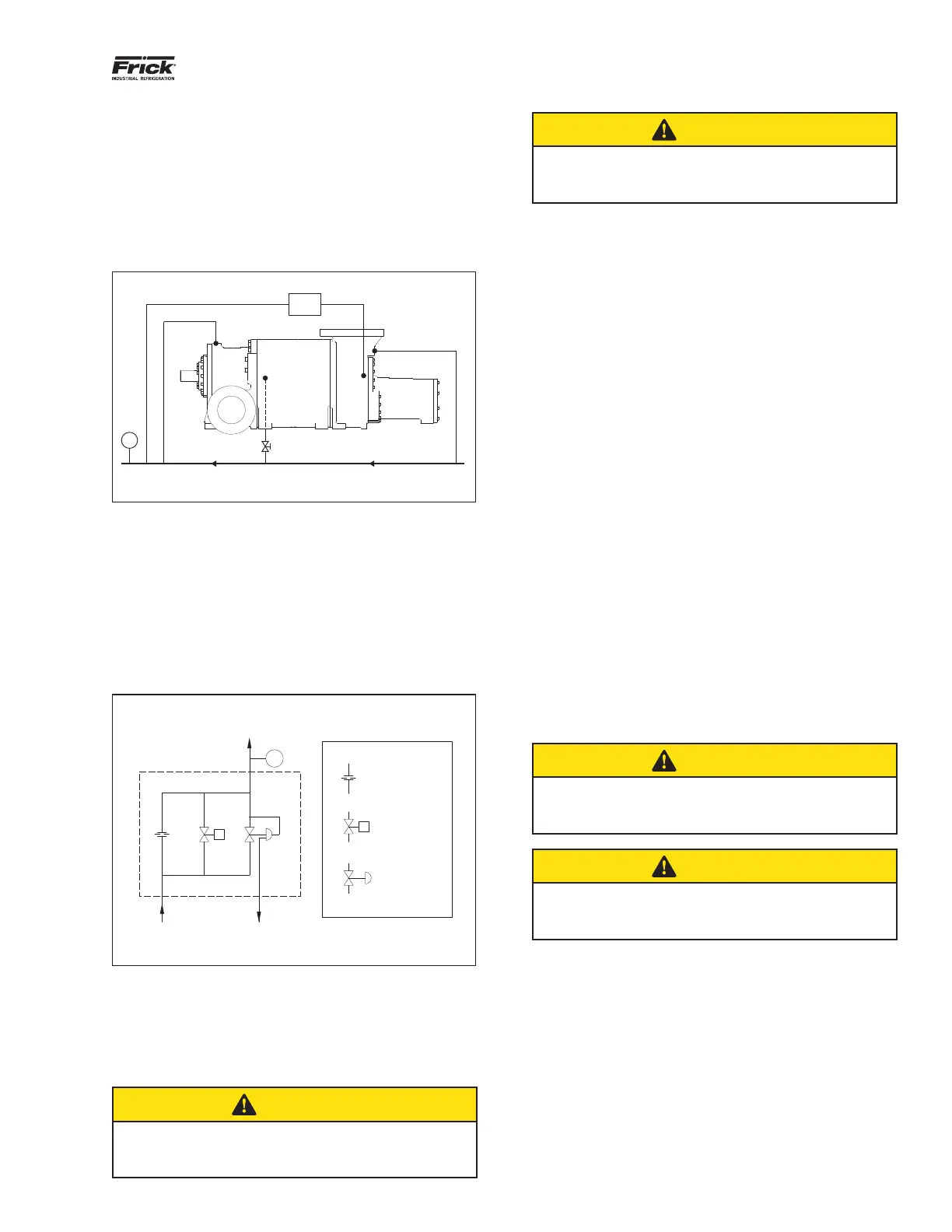

Figure20showsastandardcongurationforthe355com-

pressor.ThiscongurationlowersoilpressuretoSB-2tobe

55 psi below discharge pressure when SV < 65%. Contact

the factory formore specic conguration information.

In the case that application and/or operating conditions

change, review the BPR settings. Conguration changes

may be necessary, in which case, contact engineering. Use

theCompressorOperatingLogSheettollinyournominal

operating conditions.

Oil Feed

From Header

Restriction

Orifice

Solenoid

Valve

Pressure

Regulating

Valve

To Compressor

Discharge Line

To Inlet Bearing Oil

SB-2 Port

P

S

S

Figure 20: Example BPR conguration

Note: On all SGX compressors except the 408 models, the

oil feed also lubricates the inlet bearings. For the 408 com-

pressor (MK 2 version), the bearings are lubricated from the

SB-4 connection. For low differential applications, it is not

necessary to pipe the SB-2 port.

Caution

Operating with incorrect balance piston pressure set-

tings and selection signicantly increases the risk of

compressor breakdown and reduced compressor life.

Caution

Changes to application and operating conditions may

change oil pressure requirements to the SB-2 port and

Balance Piston Regulator conguration settings.

Compressors with squeeze lm damper (SFD)

Compressor models with an X as the third character have

Squeeze Film Dampers (SFD) built into the rotor blocking di-

ameters (Fig. 15). The SFDs provide dampening of the rotor’s

movement reducing impacts and lowering the total vibration

of the compressor. In order for the SFDs to work properly

they need to receive solid oil — oil free of bubbles and foam.

Solid oil can be attained by either:

• Pumping the oil pressure to a minimum of 36 psi above

discharge.

• Cooling the oil. With enough sub-cooling, bubbles are

prevented from forming inside the SFDs.*

Compressor ports SB-3 and SB-4 supply oil to the SFDs. As

theoilowcanbesignicant,thefeedlinesmusthavea

well dimensioned size to keep the pressure drop low. Con-

nect each line directly to the main oil header (Fig. 17). Some

applications with low power consumption and a smaller

motor may not have additional pressure and/or temperature

requirements.

FRICKCoolWarecancalculateoilows,pressureandtem-

perature required. Add all nominal operation conditions,

including SB-3 and SB-4 oil pressure requirements, to your

operation log. In the case of application and/or operating

conditionchanges,itisnecessarytoreviewoilowsand

settings.Expectcongurationorsettingchanges.Fillinthe

nominal operating conditions in your Compressor Operating

Log Sheet, and revise as needed when the situation changes.

Caution

Operating with incorrect oil pressure to the SB-3 and

SB-4 ports causes risk of high compressor vibration,

reduced compressor life and breakdown.

Caution

Changes to application and operating conditions may

change oil pressure and temperature requirements to

the SB-3 and SB-4 ports.

Oil cooling requirements

Compressor oil needs to be cooled to control the discharge

temperature, maintain proper oil viscosity, and to preserve

the life of the oil. For normal refrigeration applications, dis-

charge temperature is within the 170°F to 180°F range (see

CoolWare

™

).

One application that typically requires higher discharge

temperatures (as high as 280°F) is natural gas gathering

at the wellhead. Moisture is normally present in the gas

and it is imperative that the discharge temperature be at

least 30°F higher than the discharge dew point tempera-

ture for the gas. Run CoolWare with the Water Saturated

*Reference CES 3680 for SFD requirements.

Loading...

Loading...