070.650-IOM (JUL 19)

Page 31

SGC/SGX ROTARY SCREW COMPRESSOR

INSTALLATION

ELECTRICAL INSTALLATION

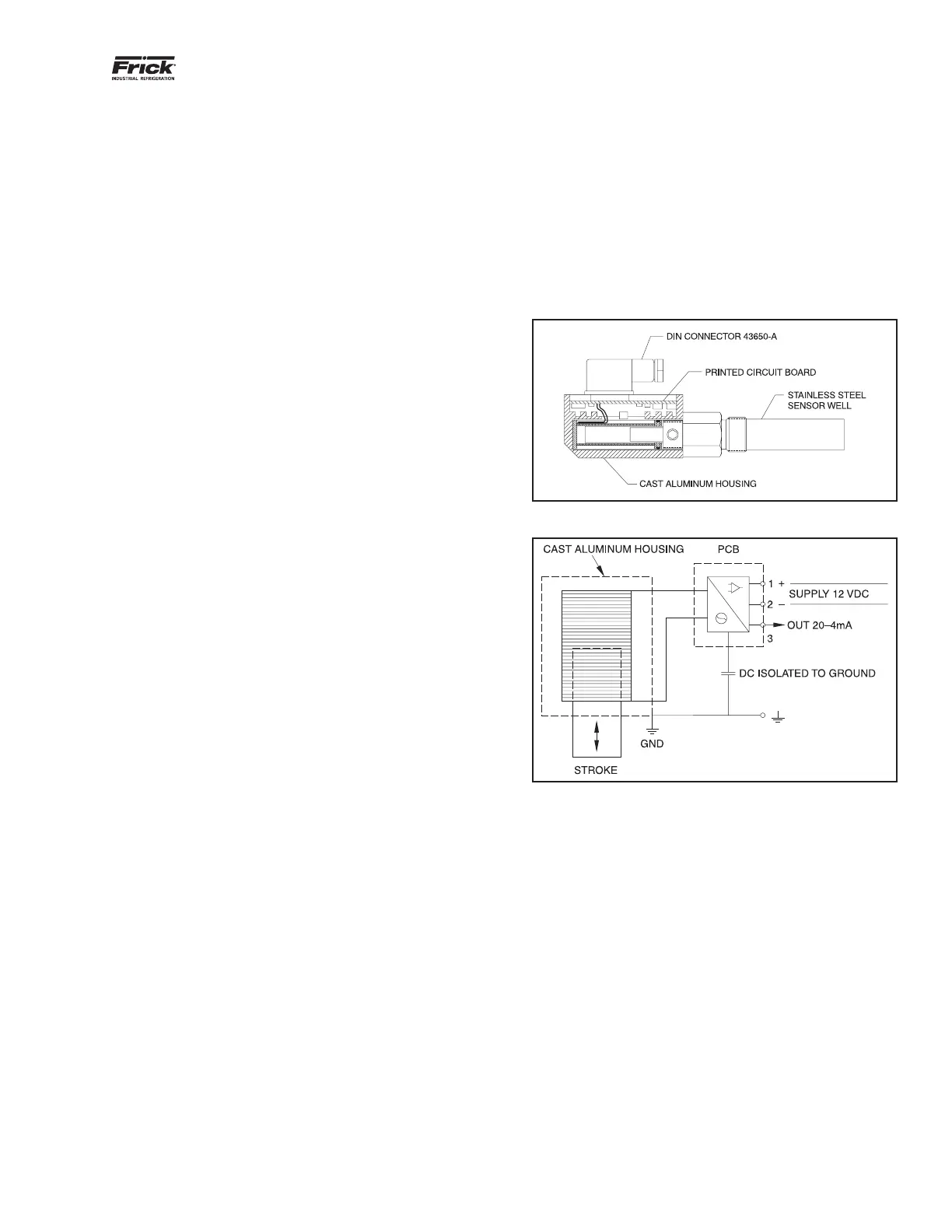

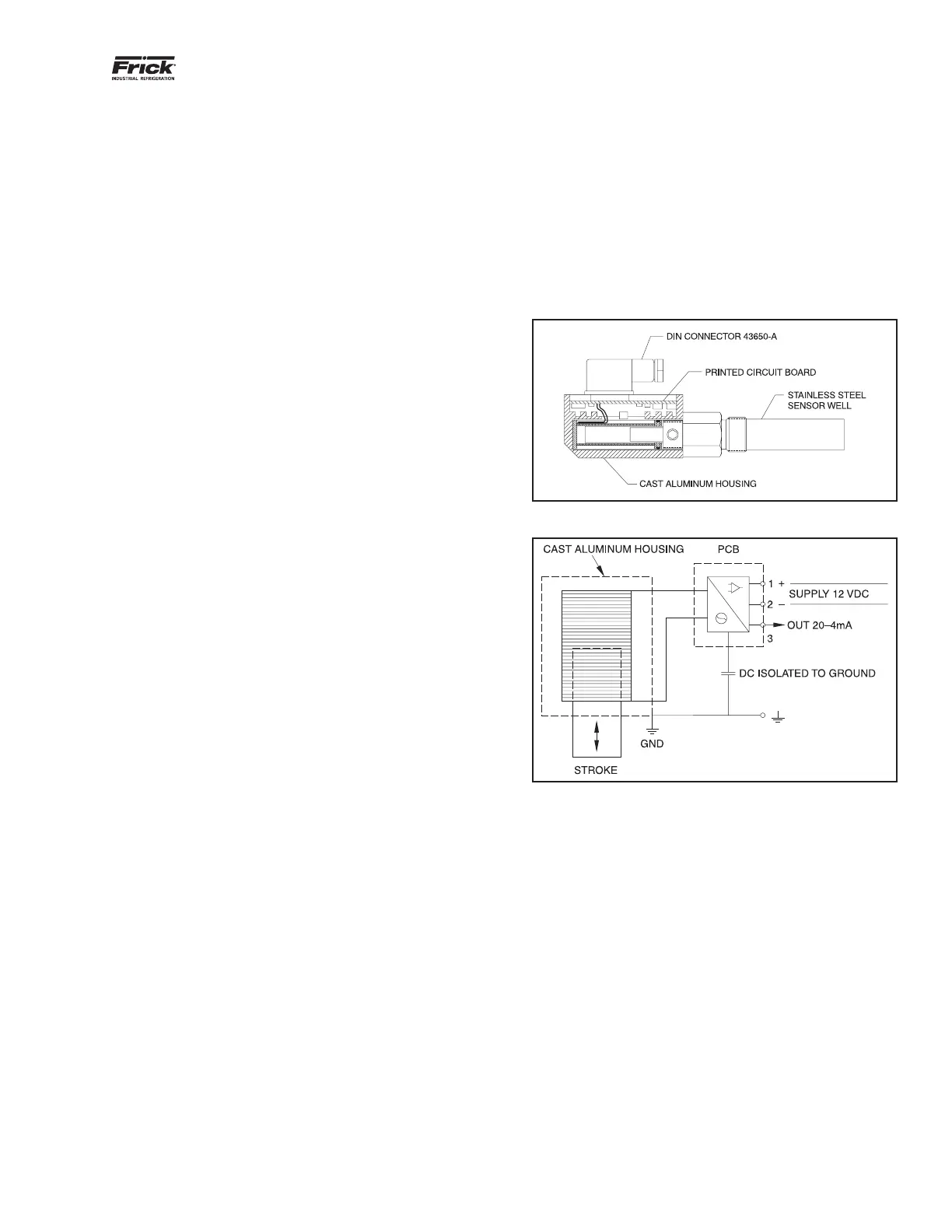

SLIDE STOP TRANSMITTER

The slide stop transmitter (Figure 21) measures the position

of the slide stop (SS) using a 20 to 4 mA signal to cover

the range of minimum to maximum Vi. The signal is sent

to your control system so that it can adjust the position of

SS according to system pressures. The correct SS position

is important to achieve the most efcient compressor

operation. Connect to +/- and signal as shown in the wiring

diagram in Figure 22. Refer to FRICK Compressor Control

Panel 090.040-O for instructions for calibration procedure.

Figure 21: Slide stop transmitter

Figure 22: Wiring diagram for slide stop transmitter

CAPACITY SLIDE VALVE TRANSMITTER

The slide valve transmitter (Figure 23) measures the position

of the slide valve (SV) and sends a 4 to 20mA signal to your

control system. The controller adjusts the position of the SV

according to the motor load set point. The correct position

is important to properly load the compressor and motor.

It is important not to overload the compressor and motor.

Observe the maximum power input and ensure design

limitations are not exceeded. Connect to +/- and signal as

shown in the wiring diagram, Figure 24. Refer to 090.040-

O - FRICK Compressor Control Panel for instructions for

calibration procedure.

the mount is machined to ensure that motor to compressor

alignment is in specication (see the Motor mounting

section for mounting details).

If you are using a foot mounted motor, it is essential that

the coupling be properly aligned to ensure proper bearing

and seal performance.

1. Coupling must be selected and installed so that it

doesn’t transmit any axial load to the compressor shaft.

Set magnetic center correctly on the sleeve bearing

motors.

2. Set up the minimum distance between compressor

shaft and motor shaft to allow for seal removal (see

Outline drawings).

3. Coupling must be able to take up any misalignment

between motor and compressor. It is critical to the

life of the shaft seal that misalignment is kept to the

minimum possible value. Be sure to follow the coupling

manufacturer’s guidelines for checking and correcting

any misalignment. See the Operation section for

Johnson Controls–FRICK requirements.

COUPLING ALIGNMENT REQUIREMENTS

(FOOT MOUNTED ONLY)

Coupling alignment must be performed prior to start-

up. After the compressor has been installed on the job

site, alignment must be checked again and if necessary

corrected prior to start-up. After a few hours of operation,

the alignment must be checked while the package is still

hot. Correct hot alignment is critical to ensure the life of the

shaft seal and compressor bearings.

Maximum radial runout is .004 in. total indicator reading.

Maximum axial runout is .004 in. total indicator reading.

A dial indicator or another appropriate measuring device is

to be used to determine the Total Indicator Runout.

Indicator bracket sag must be checked as all brackets have

someexibility.Thebestwaytomeasurethisistoattach

the dial indicator and bracket on a pipe at the coupling span

distance. Zero the indicator in the 12:00 position, and rotate

the pipe so the indicator is in the 6:00 position. The reading

on the indicator in the 6:00 position is the bracket sag. This

value must be included in the dial indicator readings when

afxedtothecouplingforanaccuratealignment.

DEHYDRATION / EVACUATION TEST

Evacuate the system to 1000 microns. Valve off the vacuum

pump and hold vacuum for 60 minutes.

Pass – Vacuum cannot rise more than 500 microns during

the hold period.

Fail – Vacuum rise is more than 500 microns during the

hold period. Identify and repair any system leaks.

Repeat vacuum test until requirements are met.

Loading...

Loading...