070.650-IOM (JUL 19)

Page 4

SGC/SGX ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

Rotaryscrewcompressorserialnumbersaredenedby

the following information:

Example: 10240A90000015Z

Plant Decade Month Year

Global

Seq. no.

Additional

remarks

1024 0 A 9 0000015 Z

Plant: 1024 = Waynesboro, 1153 = Monterrey

Month

A = JAN, B = FEB, C = MAR, D = APR, E = MAY, F = JUN,

G = JUL, H = AUG, K = SEP, L = OCT, M = NOV, N = DEC.

Additional Remarks

R = Remanufactured

R1 = Rebuild

R2 = Rebuild plus

Z = Deviationfromstandardconguration

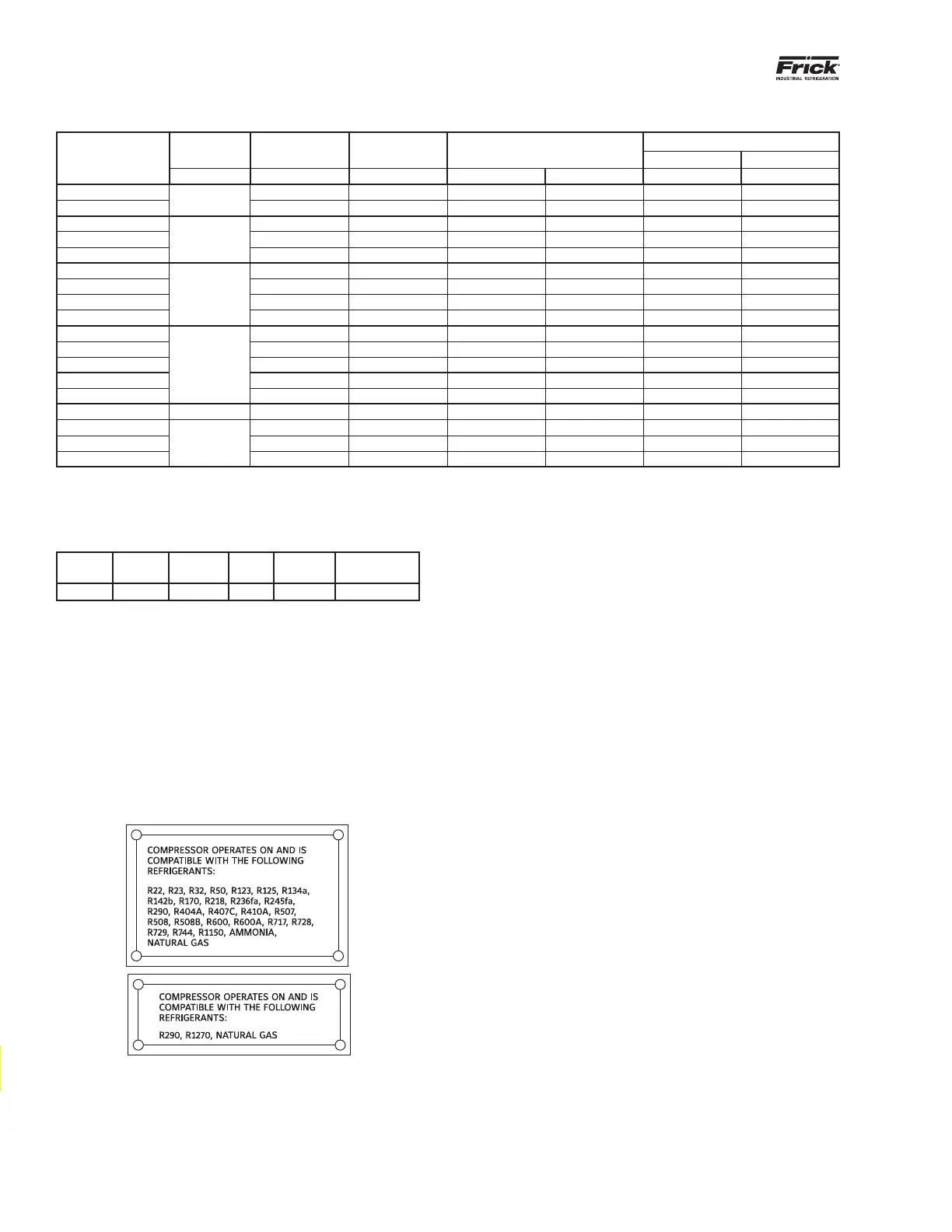

The name plates in Figure 2 show which refrigerants are

compatible with the compressor as manufactured.

Figure 2: Refrigerant name plates

LONG TERM STORAGE

Long term storage (6 months to 5 years) provisions are re-

quired, regardless of storage environment, if start-up and/

or useful operation does not occur within six (6) months of

equipment shipment. Special provisions may be required

for storage of less than six (6) months if the storage area

is subject to unusual environmental conditions such as

high humidity, large changes in temperature, or dusty

atmosphere.

The standard Johnson Controls-FRICK Warranty for an

SGC/SGX screw compressor covers twelve (12) months

from start-up or 18 months from shipment, whichever

comesrst.MakearrangementswiththelocalJohnson

Controls-FRICK service organization (arranged through

factory service) regarding surveillance and maintenance

during the storage period. It is the customer’s responsibil-

ity to submit a monthly report showing the condition of

the unit and noting any discrepancies to the guidelines

listed herein. Failure to comply with this Long Term Stor-

age recommendation may void the warranty.

Long term storage of equipment may lead to the dete-

rioration of components over a period of time. Synthetic

components in the compressor may deteriorate over

timeeveniftheyarekeptoodedwithoil.Awarmand

dry environment is essential to minimize environmental

and corrosion damage. Long term storage of the affected

equipment at a customer’s site may involve additional re-

quirements. Visit the Johnson Controls web site, www.jci.

com/FRICK,forspecicinstructions(Location:BareCom-

pressors\General\Warranties\Screw Compressor Purchased

for Long Term Storage).

Following the guidelines in Preparing Compressor for Stor-

age and Maintaining Compressor in Storage to maintain

the screw compressor warranty.

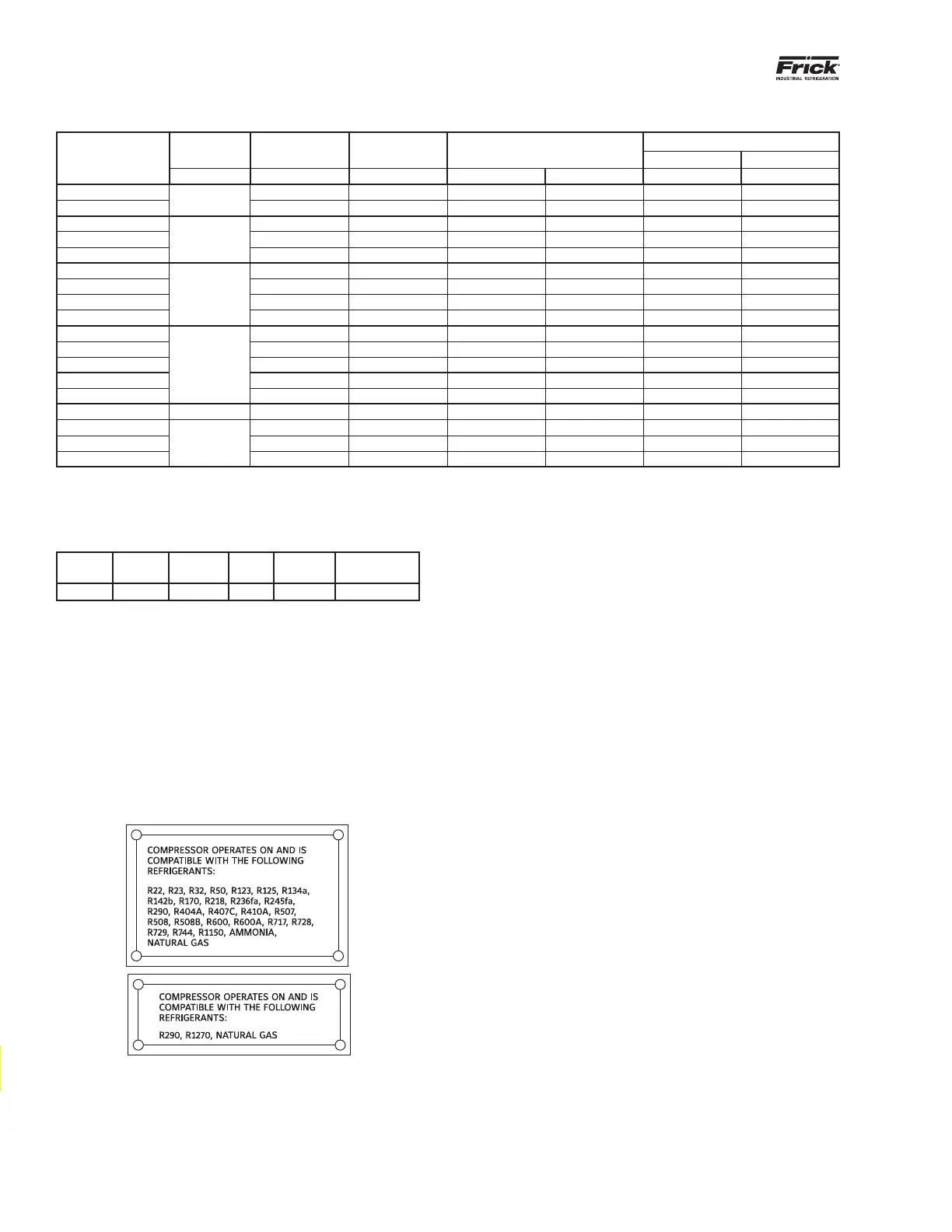

Compressor

model

Rotor

diameter

Rotor

Max

speed

Geometrical swept volume

drive shaft end

Displacement

3550 rpm 2950 rpm

mm L/D rpm ft³/ rev m³/rev cfm m³/h

SGC 1913

193

1.35 4,500 0.16653 0.004713 591 834

SGC 1918 1.8 4,500 0.22204 0.006284 788 1,112

SGC 2313

233

1.35 4,500 0.29301 0.008292 1,040 1,468

SGC 2317 1.7 4,500 0.36897 0.010442 1,310 1,848

SGC 2321 2.1 4,500 0.45580 0.012899 1,618 2,283

SGC 2813

283

1.35 4,200 0.52501 0.014858 1,864 2,630

SGC 2817 1.7 4,200 0.66115 0.018711 2,347 3,312

SGC 2821 2.1 4,200 0.79546 0.022512 2,824 3,985

SGC 2824 2.4 4,200 0.89858 0.025430 3,190 4,501

SGCH/B 3511

355

1.1 3,600 0.82248 0.023276 2,920 4,120

SGCH/B 3515 1.5 3,600 1.12154 0.031739 3,981 5,618

SGCH/B 3519 1.9 3,600 1.42748 0.040398 5,068 7,150

SGXB 3519 1.9 3,600 1.42748 0.040398 5,068 7,150

SGXB 3524 2.4 3,600 1.80328 0.051033 6,402 9,033

SGXH 3519 355 1.9 3,600 1.42748 0.040398 5,068 7,150

SGXH 4013

408

1.3 3,600 1.41180 0.03998 5,012 7,076

SGXH 4018 1.8 3,600 1.95481 0.05535 6,940 9,798

SGXH 4021 2.1 3,600 2.31319 0.06550 8,212 11,594

Table 1: Geometrical swept volume

rewritten to state what

headings the guidelines are

under

Loading...

Loading...