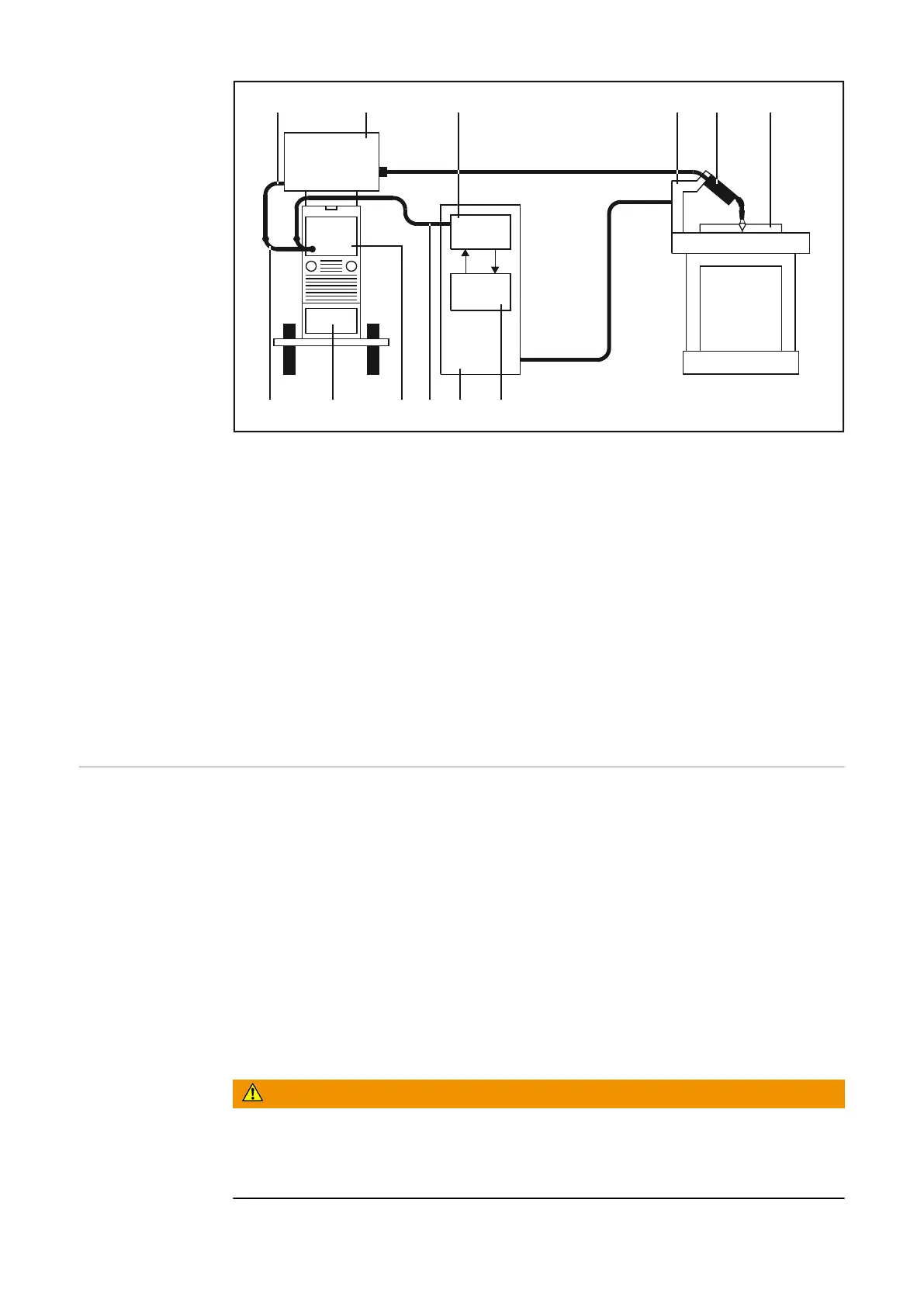

ROB 3000

in

out

Control

)9()5()21()4()3()6(

(10)(11)(7)(1)(2)(8)

Application example: ROB 3000 automatic-welder interface for automatic welding

(1) Power source

(2) Cooling unit

(3) Wirefeeder

(4) ROB 3000 automatic-welder interface

(5) Machine welding torch

(6) Interconnecting cable

(7) LocalNet connection cable

(8) LocalNet passive distributor

(9) Workpiece

(10) Automatic-welder control system

(11) Cubicle for automatic-welder control system

(12) Automatic welder

Application 3:

Automatic welder

- Job selection

via automaticwel-

der control sys-

tem

Application example of the principal commands where the Jobs are selected - and wel-

ding is being carried out - via an automatic welder

Features:

- Jobs are selected via the automatic-welder control system

- Input signals “Job BIT 0” and “Job BIT 1” are used

- Machine welding torch is guided by an automatic welder

- Welding operation is started via the “Arc ON” signal

- Input signals are specified, and output signals are processed, by the automaticwel-

der control system

Digital input signals:

- Job BIT 0

- Job BIT 1

WARNING!

Danger from unexpectedly starting welding process.

This can result in serious injury and damage to property.

▶

While the error is being remedied, the “Arc ON” signal must not be initialised, other-

wise the welding process will be activated immediately after the error is remedied.

36

Loading...

Loading...