29

With fine-globule electrodes (titanium) the above will not be observed, as metal transfer

occurs without a short circuit being produced.

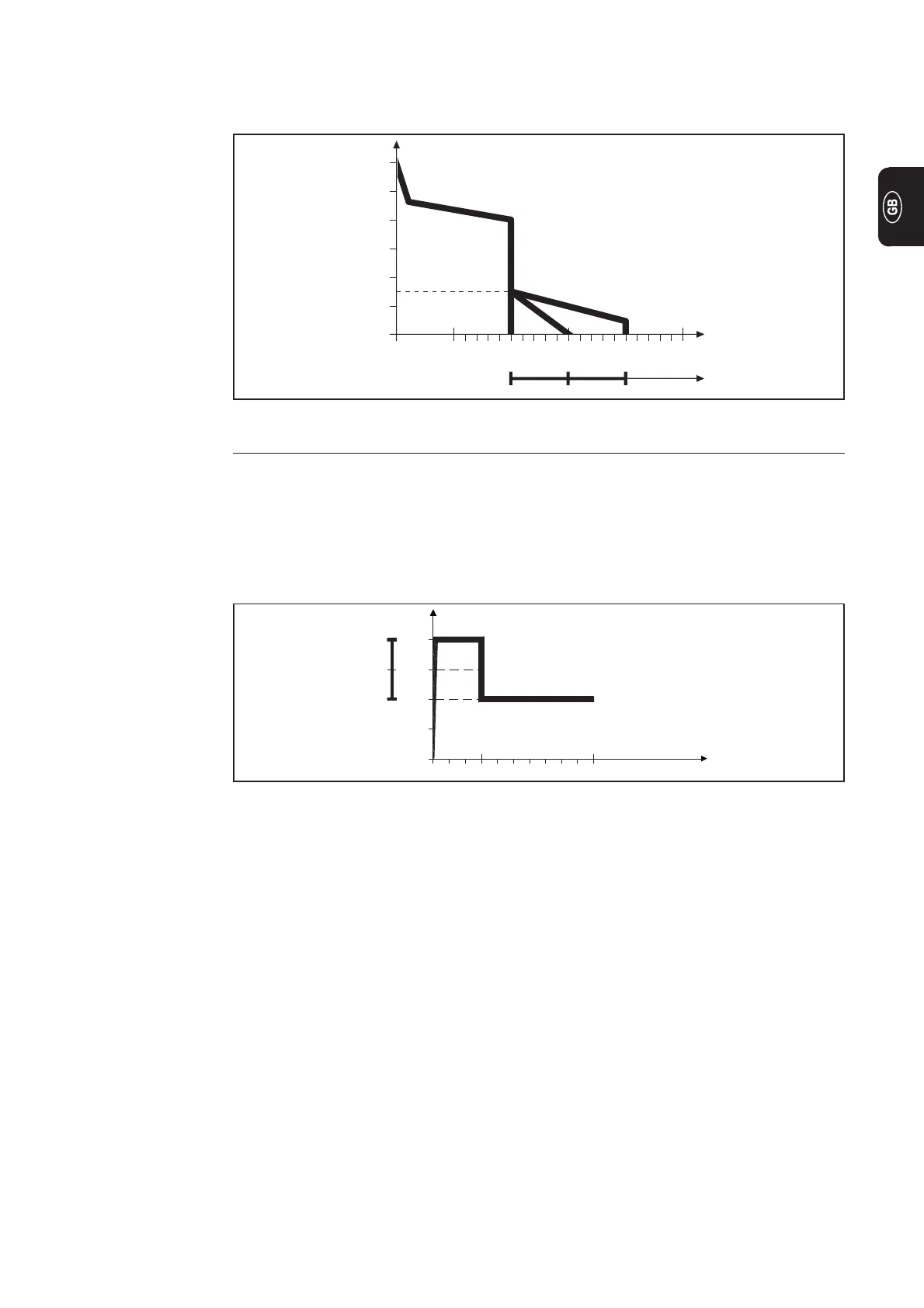

100

V

A

50 150 200 250

5

100

ARC FORCE CONTROL DIAL

Fig. 31 Effect of arc force control dial (35) on constant-current characteristic at the moment of short

circuiting. Welding current setting 100 A

(36) HOT-START control dial

- only effective in the electrode ignition phase

- improved ignition even with electrodes where ignition is normally more difficult

- improved melting of the base material in the ignition phase, meaning far fewer

cold laps

- considerable reduction of slag inclusions

- is added to the set welding current value on a percentage basis

Important! The maximum setting for the HOT-START current is limited by the maximum

circuit of the machine.

Connecting the remote control unit:

- use the remote control cable to create an electrical link bet-ween the connecting

socket [G] on the power source and the socket on the remote control unit.

- insert the plug-in connections into the correct sockets and screw the coupling ring

on as far as possible.

- shift the function selector button (4) into the right position for the operating mode in

question

Welding without a remote control unit

The parameters for Hot-Start and arc force are pre-set within the machine to average

(mean) values

60

50

40

30

20

10

0

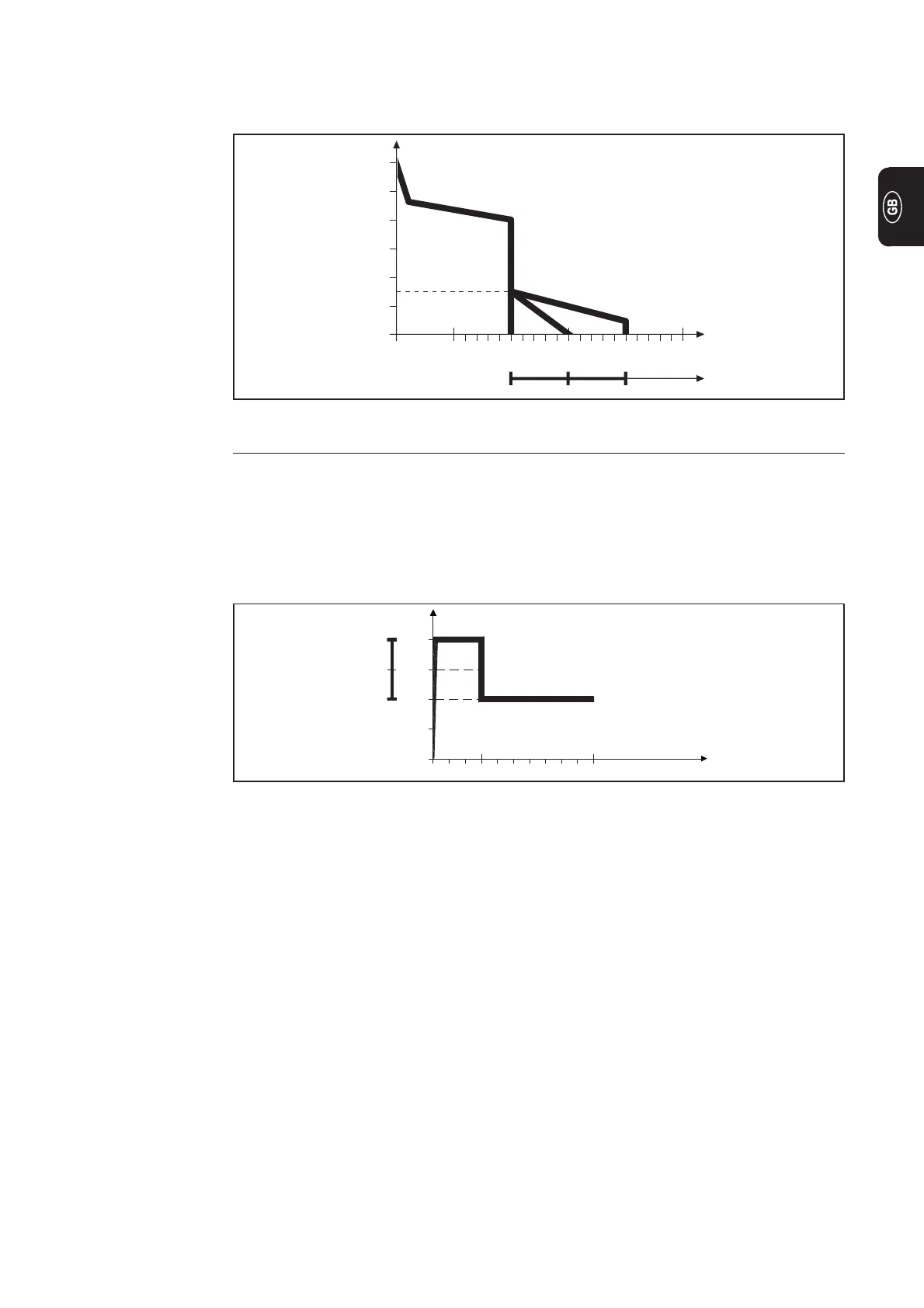

Fig. 32 Ignition phase using HOT-START control. Welding current setting 100 A

A

200

150

100

0 1.0 t sec

50

HOT-START

0

100%

TPmc remote

control unit

(continued)

Loading...

Loading...