Frymaster 1814 Series Gas Fryers

Chapter 3: Installation

3-5

3.4 Gas Connections (cont.)

H. Flexible Couplings, Connectors and Casters: If the fryer is to be installed with flexible

couplings and/or quick-disconnect fittings, the installer must use a heavy-duty AGA design-

certified commercial flexible connector of at least ¾" NPT (with suitable strain relief), in

compliance with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69-

(latest edition) and Addenda Z21.69a-(latest edition). Quick disconnect devices must comply

with the Standard for Quick-Disconnect Devices for Use with Gas Fuel, ANSI Z21.41-(latest

edition).

1. For an appliance equipped with casters, the installation in the U.S. shall be made with a

connector that complies with Standard for Connectors for Movable Gas Appliances, ANSI

Z21.69-(latest edition) and Addenda Z21.69a-(latest edition). In the European Union, use a

flexible coupling certified as NF D 36123 (or other national standard) or a quick disconnect

device certified NF D 36124 (or other national standard). The coupling shall be periodically

examined and replaced as necessary.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping. Personal

injury may result.

2. The fryer must be restrained by means independent of the flexible coupling or

connector in order to limit the movement of the fryer.

3. If disconnection of the restraint is necessary, this restraint must be reconnected after

the fryer has been returned to its originally installed position.

I. After hook-up, bleed the gas line of air to ensure that the pilot light will ignite quickly.

AUSTRALIAN REQUIREMENTS

To be installed in accordance with AS 5601, local authority, gas, electricity, and any other relevant

statutory regulations.

3.5 Gas Specifications

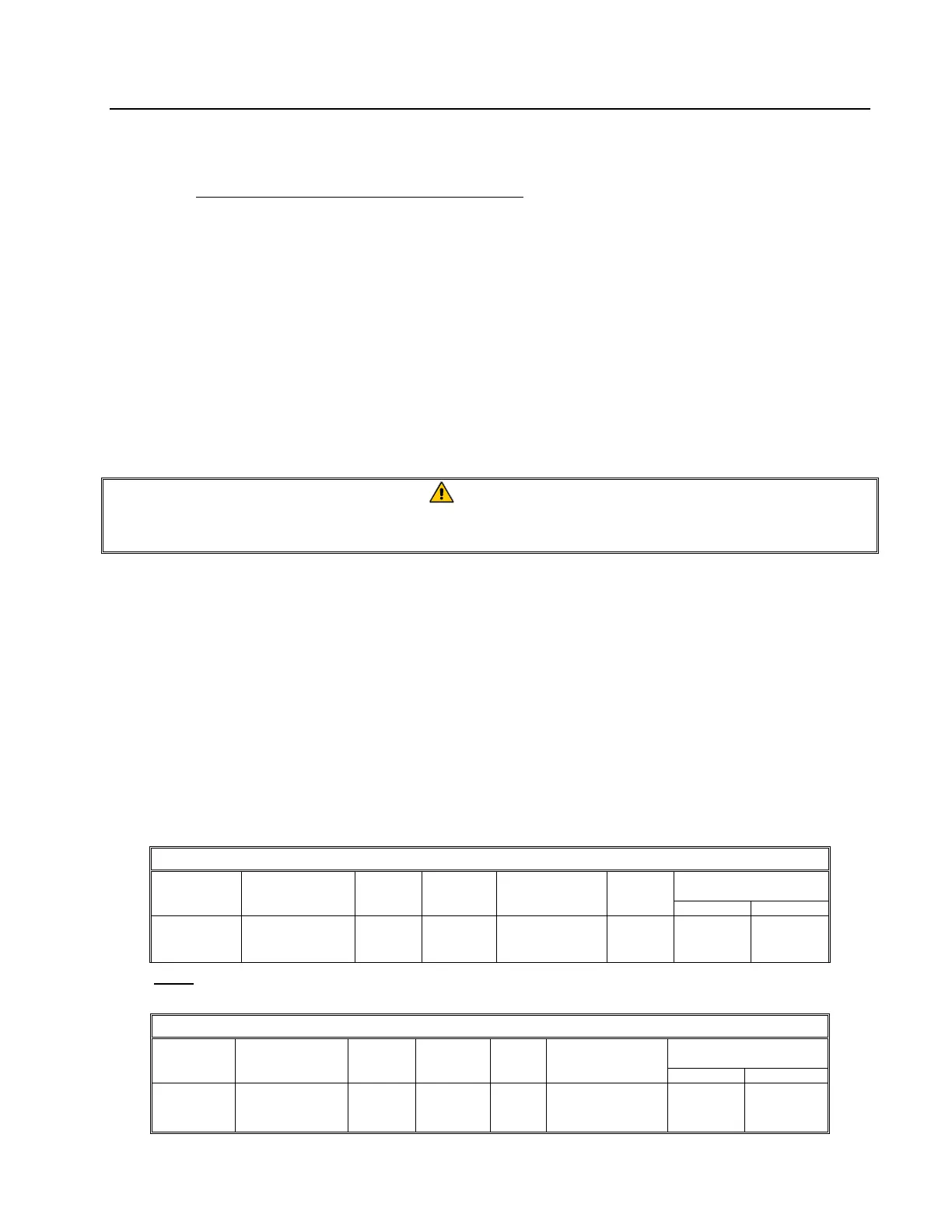

NON-CE

Altitudes of 2000 feet or less

MODEL

INPUT

(BTU)

GAS

TYPE

ORIFICE

(MM)

ORIFICE

PART NO.

QTY

EQUIPMENT

PRESSURE

MBAR INCH W.C.

1814 115

NAT

LP

2.26(#43)

1.40(#54)

810-2049

810-2324

5

5

10

27.5

4

11

NOTE: Outlet gas pressure must be adjusted strictly within the above requirements 5 to 10 minutes after the appliance is operating.

(Pilot Flame Adjustment: Turn the pilot adjustment screw clockwise/counter-clockwise until the desired flame-volume is achieved.)

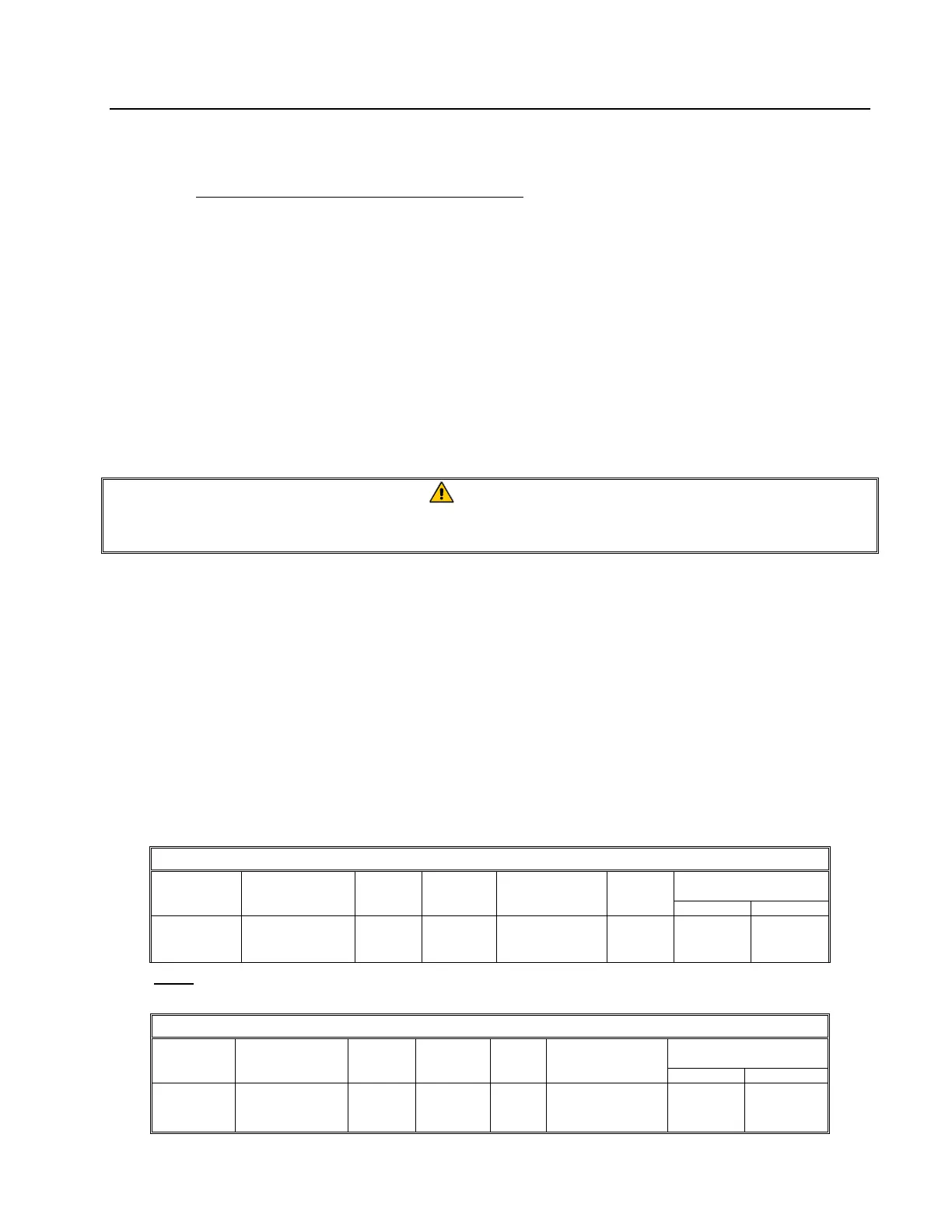

CE ONLY

Altitudes of 2000 feet or less

MODEL

INPUT

(kW)

GAS

TYPE

ORIFICE

(MM)

QTY

PILOT ORIFICE

(MM)

EQUIPMENT

PRESSURE

MBAR INCH W.C.

1814 33,7

G20

G25

G31

2,2

2,2

1,4

5

5

5

.46

.46

.33

10,0

15,0

23,9

4,0

6,0

9,5

Loading...

Loading...