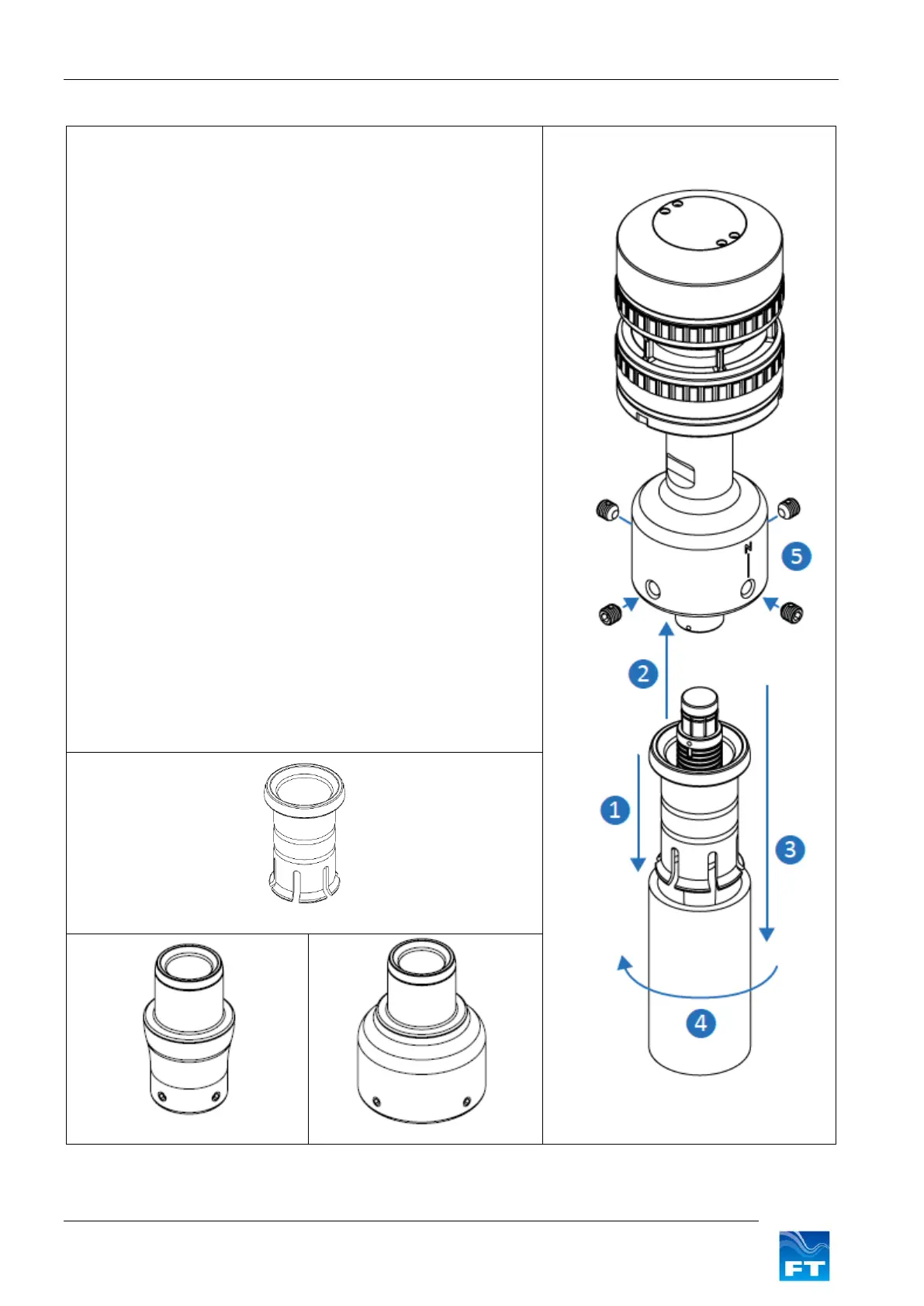

1. Push the slotted end of the pipe insert into the mounting pipe.

Apply a continuous seam of all-weather adhesive sealant

around each of the two channels, before pushing the insert fully

into the pipe, ensuring the shoulder is flat and any surplus

sealant is wiped away. This insert provides a smooth transition

for the sensor O ring to facilitate easy mounting of the DM with

no damage to the internal O ring (for alternative pipe sizes use

the available size adaptors)

2. Pass the cable through the mounting pipe and pipe insert

3. Connect the cable to the wind sensor and lower the DM base

onto the pipe

4. Rotate the sensor to align the central North (‘N’ datum, feature)

with magnetic North (or an alternative reference)

5. Tighten four self-locking fasteners (4x part FT034) ensuring an

even distribution of pressure and firm contact with the mounting

pipe. The fixings use a thread-locking insert and will provide

resistance before they are fully engaged. In highly corrosive

environments (such as coastal installations) the use of marine

grade self-adhesive tape (such as USCGFP by 3M) is

recommended to apply over the top of the mounting fasteners

to ensure ease of removal. In these environments, it is also

beneficial to apply sealant around the base of the sensor at the

pipe interface to reduce build-up of corrosion that could make

sensor removal difficult.

Confirm the installation is safe and appropriate for the

environment.

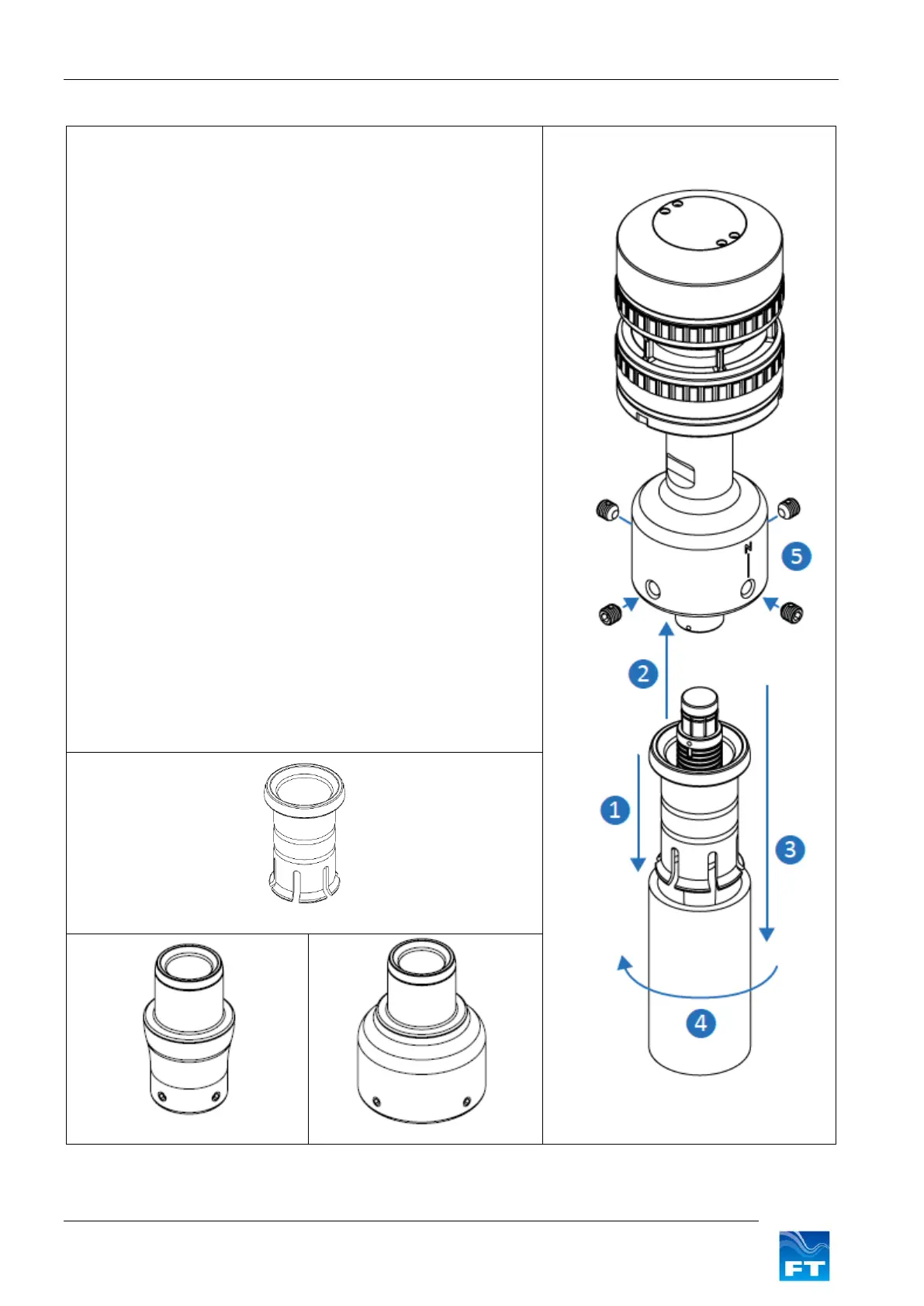

FT provides optional size adaptors to suit mounting diameters of

25mm (FT031) and 50mm (FT032). Ensure the internal diameter

allows the interface cable to pass through.

Loading...

Loading...