26

WWW.FUHR.DE

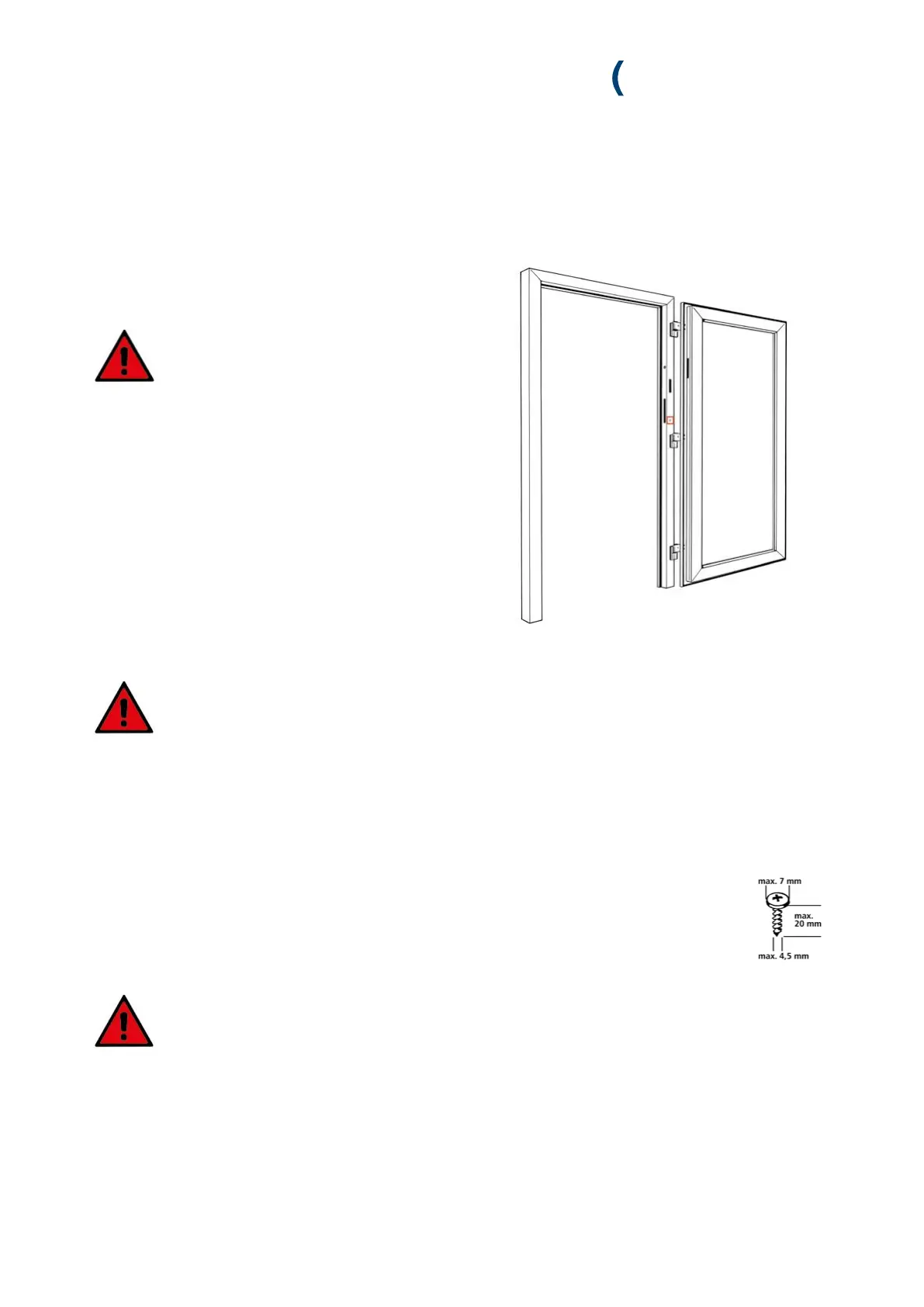

multitronic

881/881GL/ServoAccess

4.1.7 DRILL HOLE FOR THE 230 V CABLE ON THE INSTALLATION VERSIONS 3 AND 4

All routing and drilling work must be deburred carefully. The cables must be securely fixed in this area

in order to prevent abrasion. All routing and drilling swarf must carefully removed from the profiles.

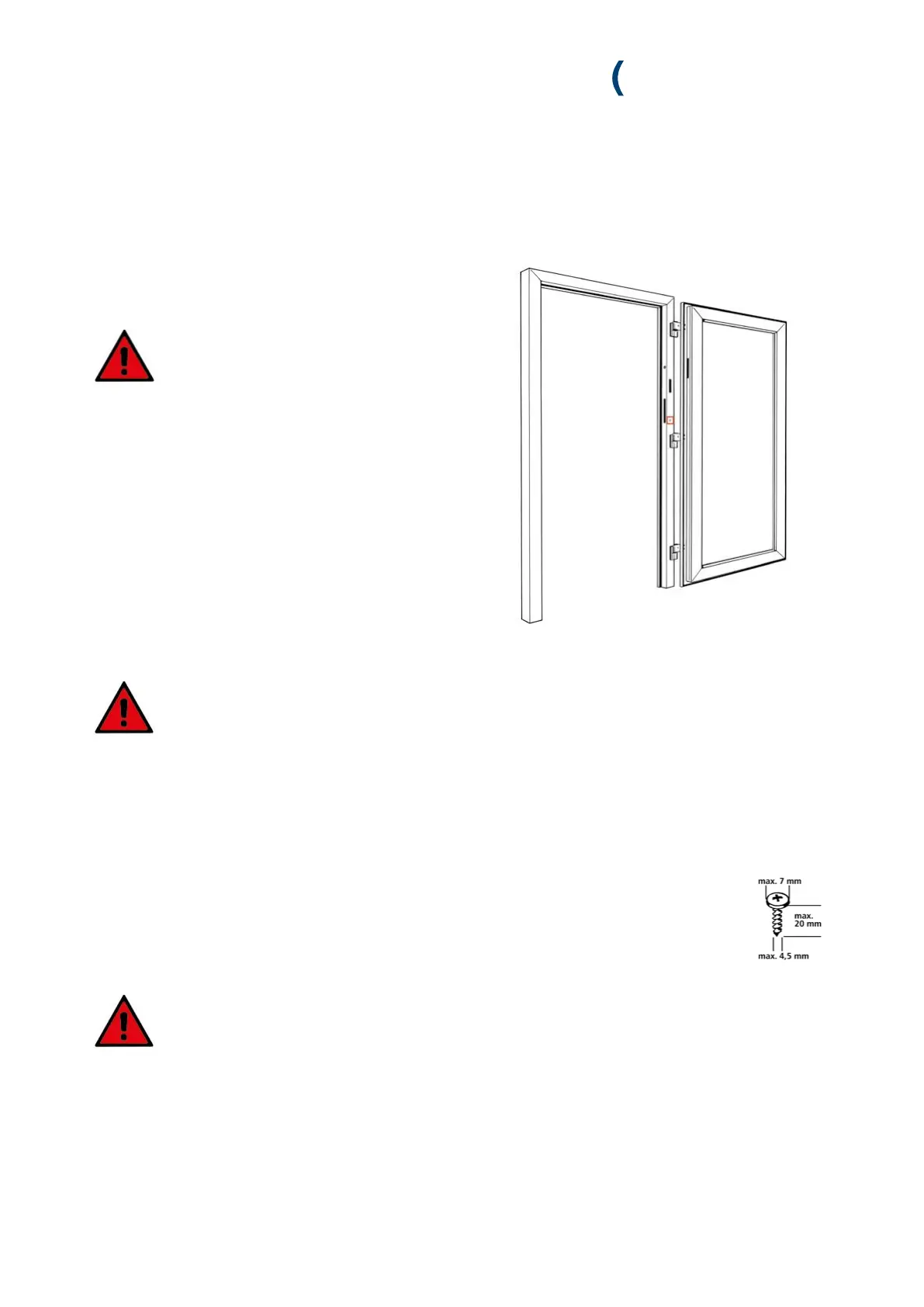

Conventional fenestration screws with a maximum screw head diameter of 7 mm and a maximum screw

diameter of 4.5 mm may be used. The PVC components (switching power supply unit, surface-contact

device etc.) are to be fixed with screws with a maximum length of 20 mm. To fix the metal compo-

nents (faceplates, keeps etc.) select a screw length according to the requirements.

Depending on the profile material, screw holes may have to be pre-drilled with an appropriate drill.

It is imperative that all screws are hand-tightened (maximum torque 1 Nm), as

some components are made of PVC and may be damaged by the excessive force

that a cordless screwdriver can exert.

It is essential that the surface-contact device and the tappet contact device are

aligned accurately.

4.1.8 SAFETY INSTRUCTIONS

4.1.9 SCREWS FOR FIXING INDIVIDUAL COMPONENTS

Drilling on the back of the profile within the cut-out for the

switching power supply unit

This drill hole must deburred carefully at

both ends! Insert the cable protection sleeve

provided in the drill hole to protect the

230 V cable. The cable must be protected

against abrasion and securely fixed in order

to prevent tractive forces.

Loading...

Loading...