GFSE-Std-0499

2 2

13

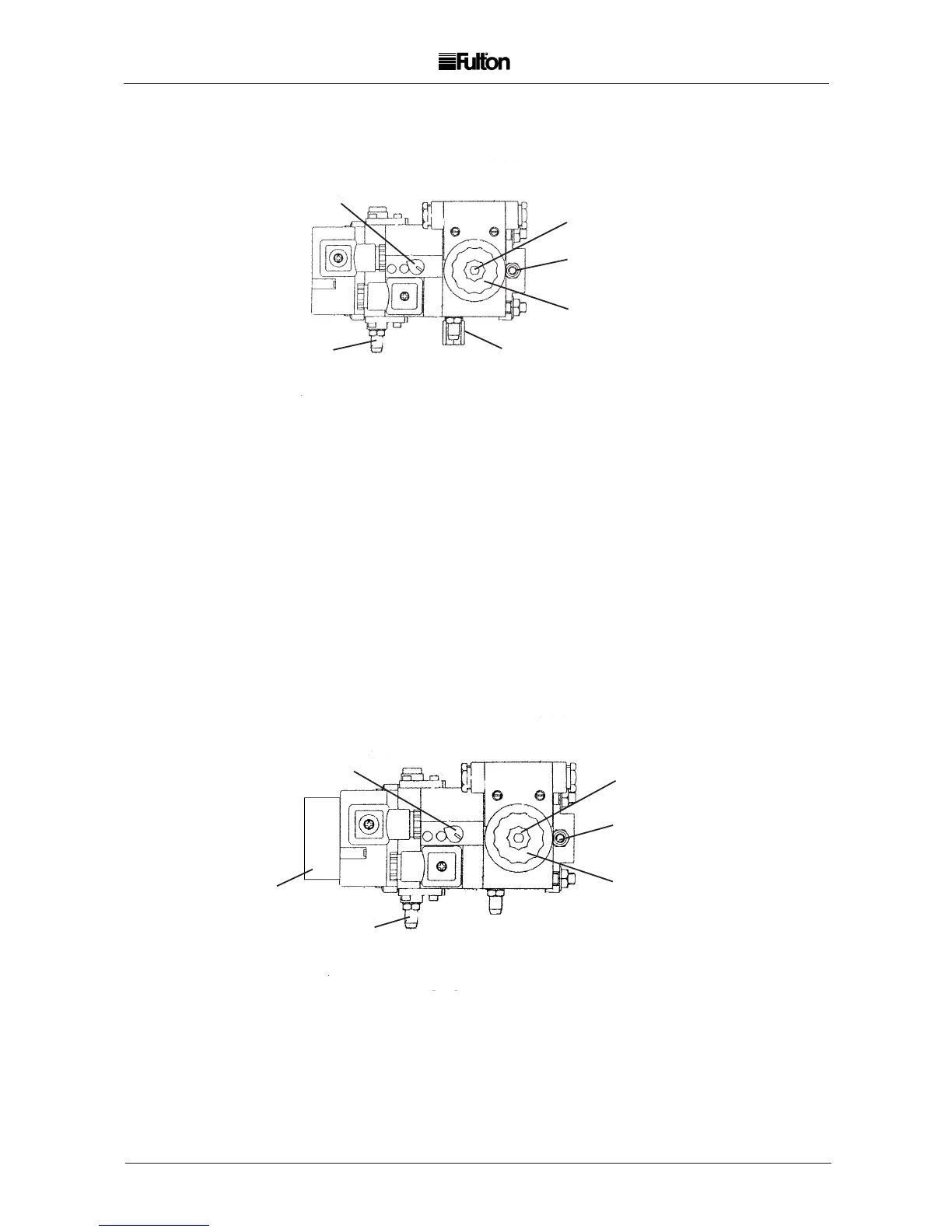

ADJUSTMENTS ACTION

A Main and Pilot Gas Governor. Turn clockwise to increase gas pressure. Range 4 - 20 mbar.

B First and second stage -

initial lift adjuster, main gas valve.

C Main gas throughput Slacken locking screw, turn fluted knob anticlockwise

to increase, clockwise to decrease.

D Gas supply test point

E Boiler side test point

F Low gas pressure switch

B

E

F

C

D

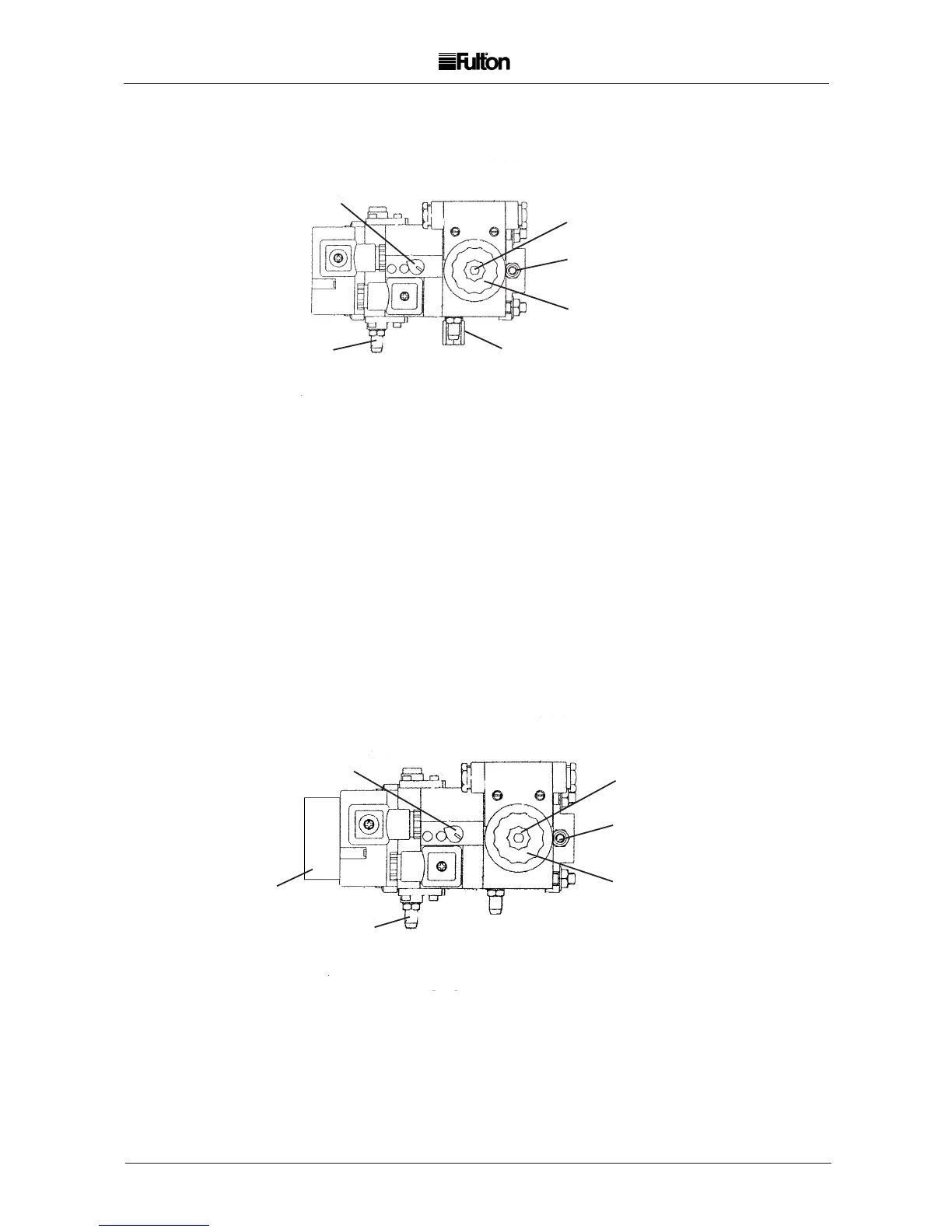

ADJUSTMENTS ACTION

A Main and Pilot Gas Governor. Turn clockwise to increase gas pressure. Range 4 - 20 mbar.

B Pilot gas range. Turn anticlockwise to increase and clockwise to decrease rate.

C First and second stage -

initial lift adjuster, main gas valve.

D Main gas throughput Slacken locking screw, turn fluted knob anticlockwise to

increase, clockwise to decrease.

E Gas supply test point

F Boiler side test point

C

D

B

E

F

MONOBLOC GAS VALVES (FIG. 9)

ADJUSTMENTS 6E - 30E (MBDLE 407/412 B07)

(With in built pilot bypass valve)

Pilot gas rate should be set to a maximum of 10% of the full fire gas throughput.

A

A

ADJUSTMENTS 6E - 30E (MBDLE 407/412 BO1)

The Monoblock gas valve operates in two stages through two main shut-off valves:-

Stage 1. The first valve opens fully and the second valve opens slowly such that the

maximum gas flow rate during the start gas proving period does not exceed 30% of the full

firing rate.

Stage 2. The second valve is fully open.

NOTE: The time taken to open fully is set by the adjustment of the first and second stage initial lift adjuster.

Loading...

Loading...