GFSE-Std-0499

3 3

24

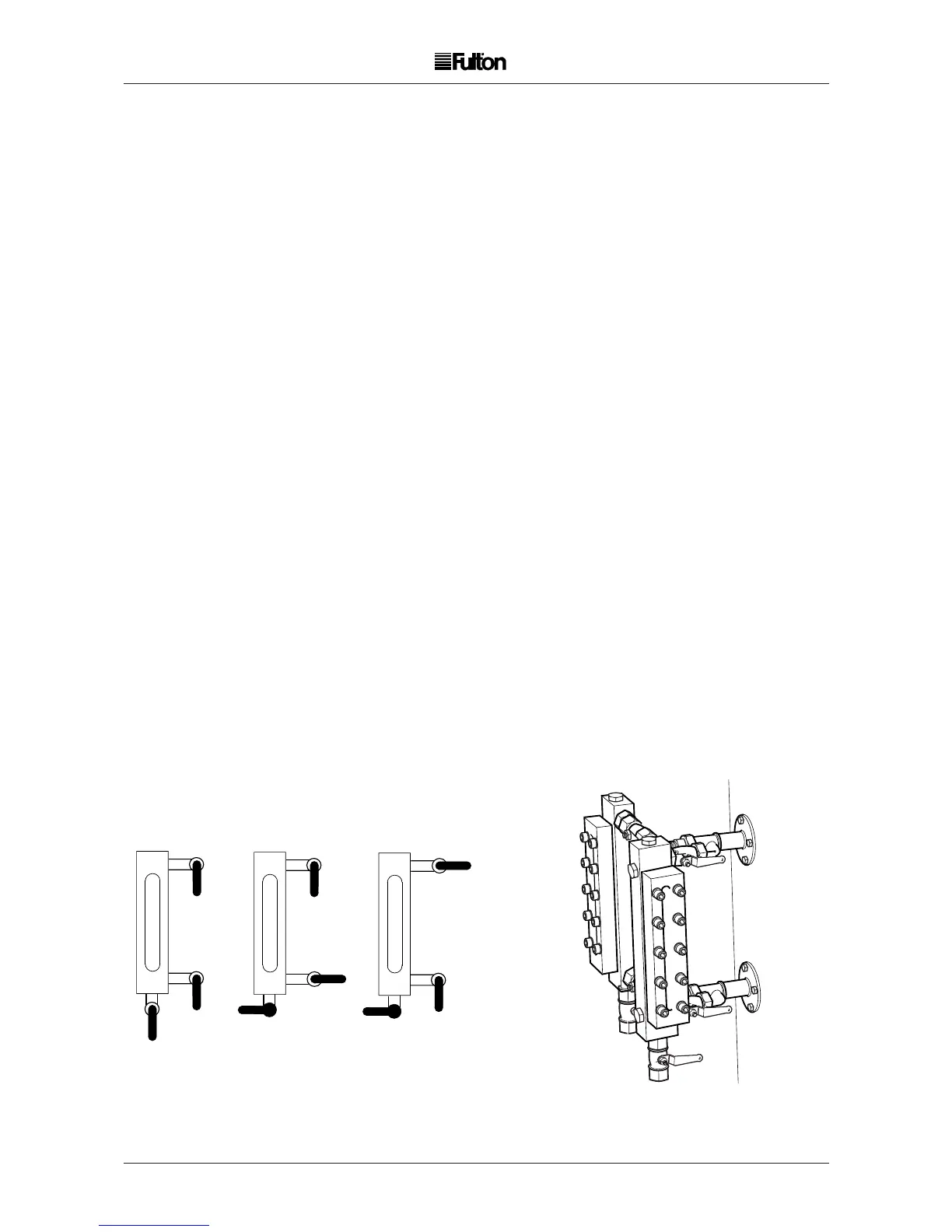

FIG. 14 LEVER TYPE - WATER GAUGE

A

F03190

3.7 BLOWDOWN PROCEDURES (DAILY TESTS)

Keep the boiler, water gauge, water column and interconnecting pipework free from sludge and scale

buildup by blowing down in the following manner:

(a) Start the boiler and generate not more than 10psi of steam (see note).

(b) Shut off both the burner and the pump.

Boiler Blowdown

(a) Fully OPEN the boiler main blowdown valve for not more than 10 seconds.

(b) CLOSE the valve.

NOTE: Where high levels of suspended solids are produced, longer and/or more frequent

blowdown may be required.

Water Column Blowdown

NOTE: The water column contains the pump ON/OFF probe, which is not safety interlocked.

(a) OPEN the ball valve in the water column, close after 5 seconds.

Water Gauge Blowdown

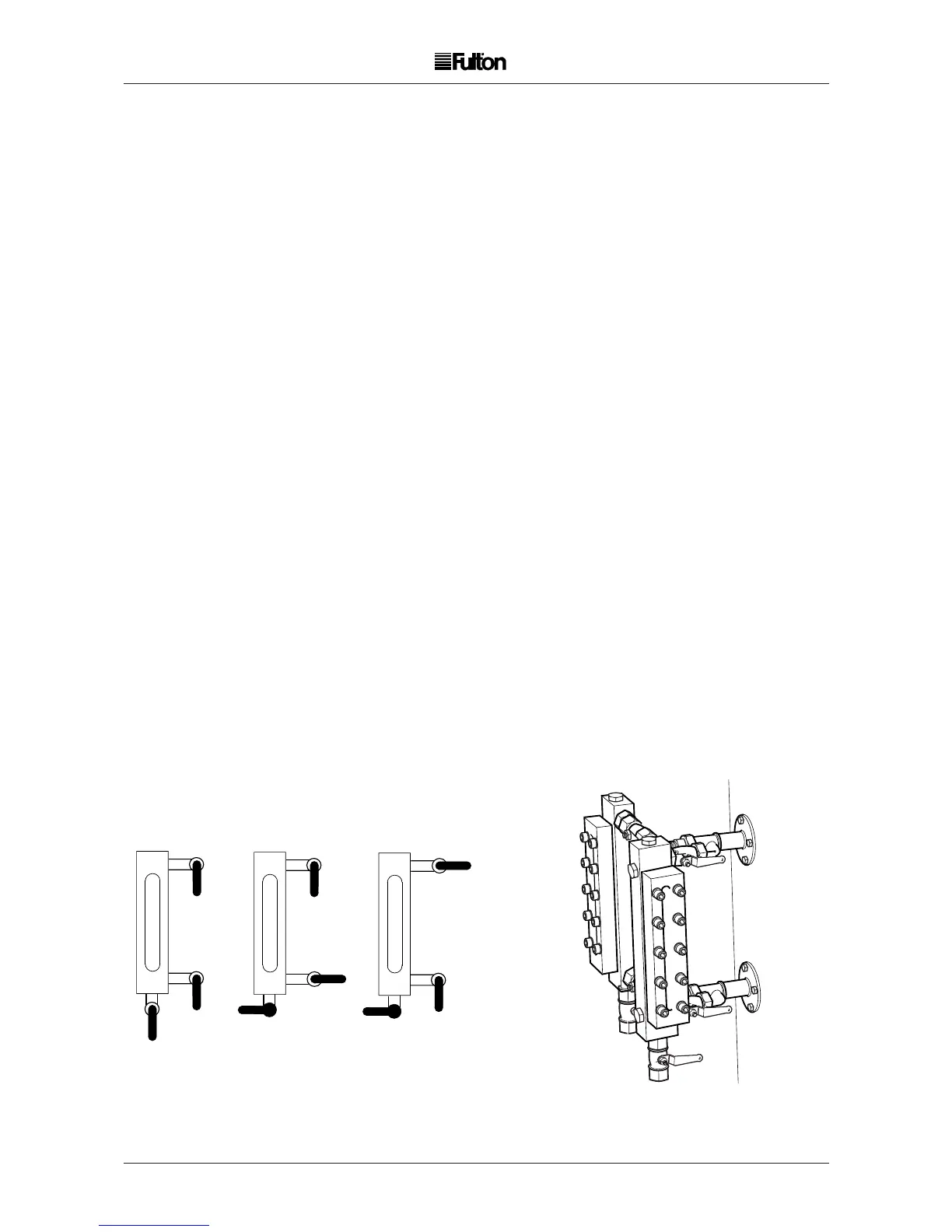

(a) Blowdown the water gauge, set 1.

1. Open the gauge glass blowdown valve A

2. Close (for approx. 3 seconds) the top gauge valve B

3. Open valve B

4. Close (for approx. 3 seconds) the bottom gauge valve C

5. Open valve C

6. Close valve A

Repeat for gauge set 2

Open the blowdown valve D for 2 - 3 seconds, close valve D

On completion of the blowdown procedure ensure that all isolation valves are OPEN and all

blowdown valves CLOSED.

NOTE: Where a Boiler is operating continuously at steam pressure, advice should be taken from a

Fulton agent as to the appropriate blowdown procedure. (refer to 3.6.5. (g) 1 - 2).

A

B

C

F03200

WORKING

POSITION

STEAM

BLOWDOWN

WATER

BLOWDOWN

Water Level Gauge operating positions.

Water Level Gauge

Set 1

Water Level Gauge

Set 2

Loading...

Loading...