GFSE-Std-0499

2 2

16

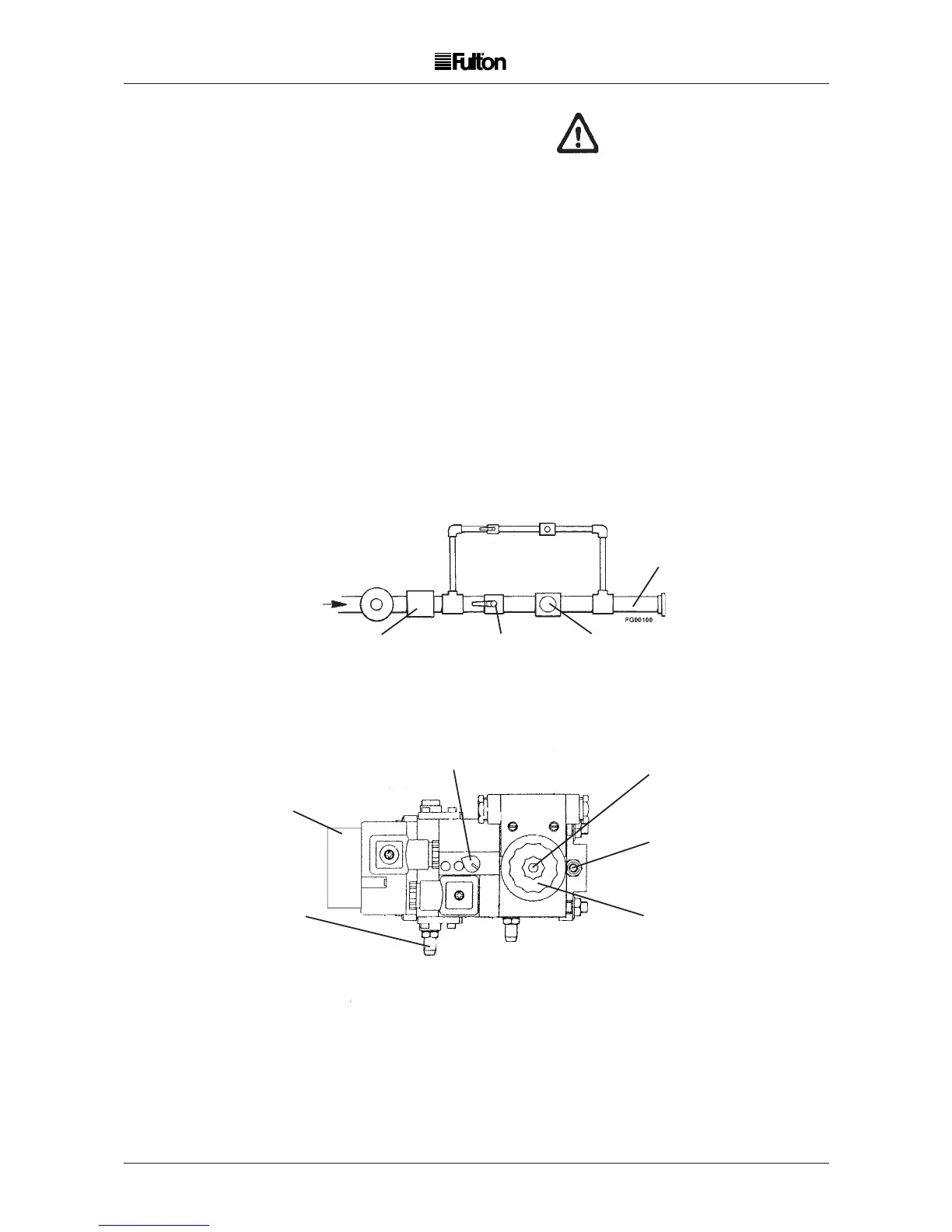

GOVERNOR

GAS START

VALVE

GAS STOP

VALVE

MAIN GAS

PILOT

ORIFICE

TUBE

PILOT

GAS

BALL VALVE

FIG. 10 L.P. GAS TRAIN

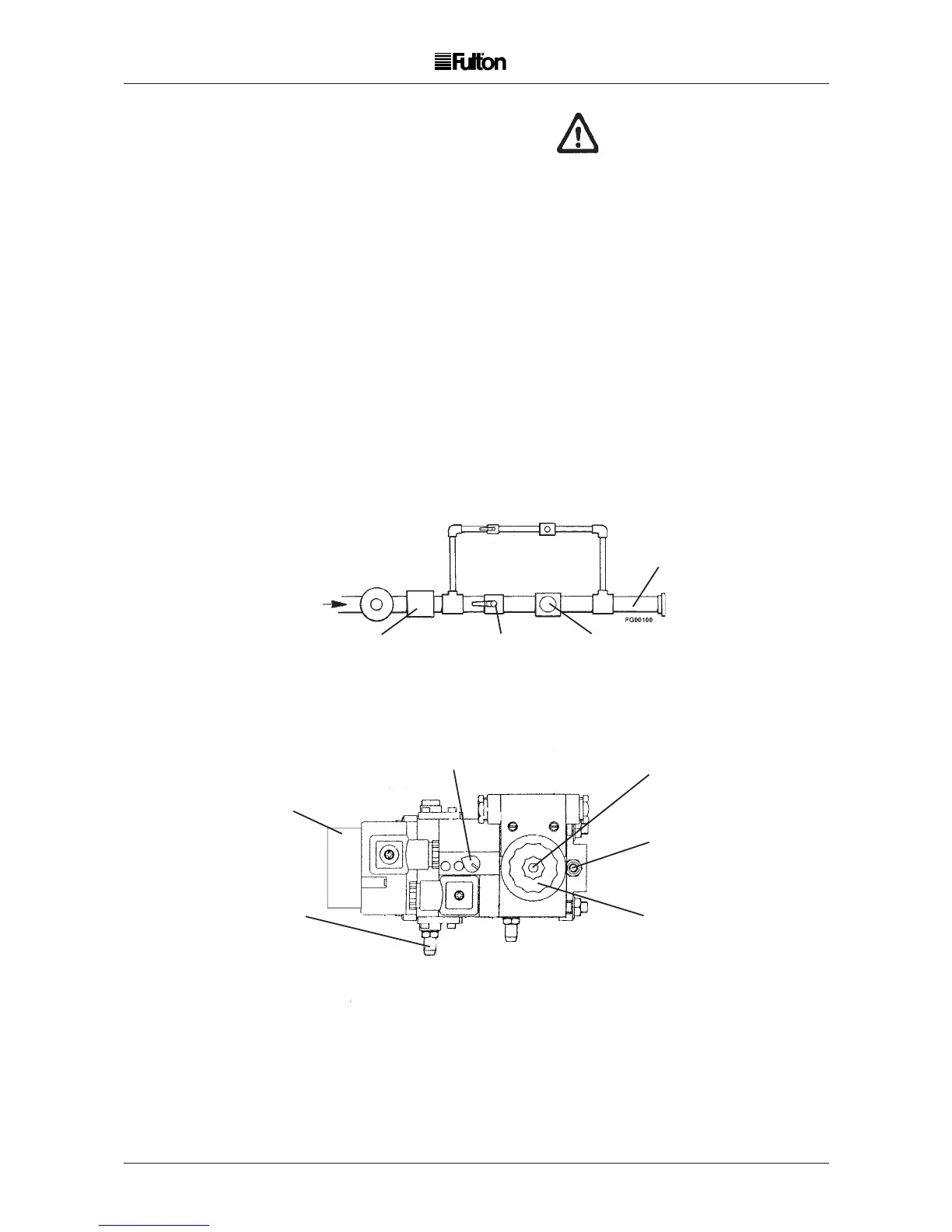

MONOBLOC ADJUSTMENTS LPG Boilers (MBZRDLE 405/412 BO1)

A

B

E

C

F

D

ADJUSTMENTS ACTION

A Main Gas Governor. Turn clockwise to increase gas pressure. Range 4 - 50 mbar.

B First and second stage -

initial lift adjuster, main gas valve.

C Main gas throughput Slacken locking screw, turn fluted knob anticlockwise

to increase, clockwise to decrease.

D Gas supply test point

E Boiler side test point

F High gas pressure switch

L.P. GAS

WARNING

Do not change the boiler fuel without

consulting the boiler manufacturer.

2.18 GAS SUPPLY - PROPANE / BUTANE

Note: LPG Boilers should be installed to the requirements of IGE/UP/10 March 2001

An L.P. gas boiler is similar in design to a natural gas boiler, the main differences are important and

must be taken into account when installing the boiler and ordering spare parts.

When installing an L.P. gas boiler, the feed from the bulk tank supply must be fitted with a supply

governor which is set to reduce the supply feed pressure to the boiler governor to 30 in. (80 mbar)

Water Column or less.

For PROPANE:-The boiler governor must be adjusted to give a firing pressure of 10 in. (25 mb) water

column at the test point provided at the elbow on the gas train.

For BUTANE:-The boiler governor must be adjusted to give a firing pressure of 8 in. (20 mb) water

column at the test point provided at the elbow on the gas train.

Gas Pressure Alarm Indicator Light

For L.P.G. applications the inlet pressure switch is used to protect the system from over pressure

and should be set at 100 mbar.

Loading...

Loading...