J OIL-E-08 2008

4

4.6 SIX MONTHLY (including three monthly)

It should be noted that after a Fulton boiler has been in operation for several months, pieces of burned metal

will be found in the space at the bottom of the boiler. These pieces of metal are the remains of a light gauge

metal form which was used during manufacture for forming the boiler insulation. This is normal and does not

affecttheefciencyorthelifeoftheboilerinanyway.

18. Removethecoverplatesandclean-outdoor.Cleanouttheuepasses.Checkthe

refractories for soot or breakage, inspect the stainless steel ring. When replacing the cover

plates and clean-out door, use furnace cement to ensure a tight seal, thus preventing the

escape of hot gases.

19. Apply a small quantity of oil to the bearings of the burner motor and the feed water pump motor.

20. Drainandushthefeedwatertank.Cleananyltersinthetank,inthefeedwaterlineorinthe

feed water pump.

21. Remove and clean the water probes, take care not to crack the porcelain. After replacement

of the probes, check the operation of the low water cutoff relay and of the feed water pump.

22. Remove the air gate and clean the fan.

23. Testtheueusingthefollowingprocedure:

Visual inspection

Checkjointsbetweenalluesectionsforqualityofseals.Wheretheuepassesthrough

the structure of the building use your judgement as to the integrity of this section of the

ue.

Smoke test

Withtheuecappedandasmokegeneratorinsertedintotheue,theirshouldbeno

smoke visible.

If either of these tests fail, shut down the boiler and contact Fulton Boiler Works immediately.

24. Remove the water gauge and water column. Rod through the top connections of both to ensure

theholesinthebafeplates(approx.6mmdia.)insidetheboilerarenotobstructed.

26. Check the burner combustion to ensure that excess air and carbon monoxide values are within

normal limits (see combustion values in section 5).

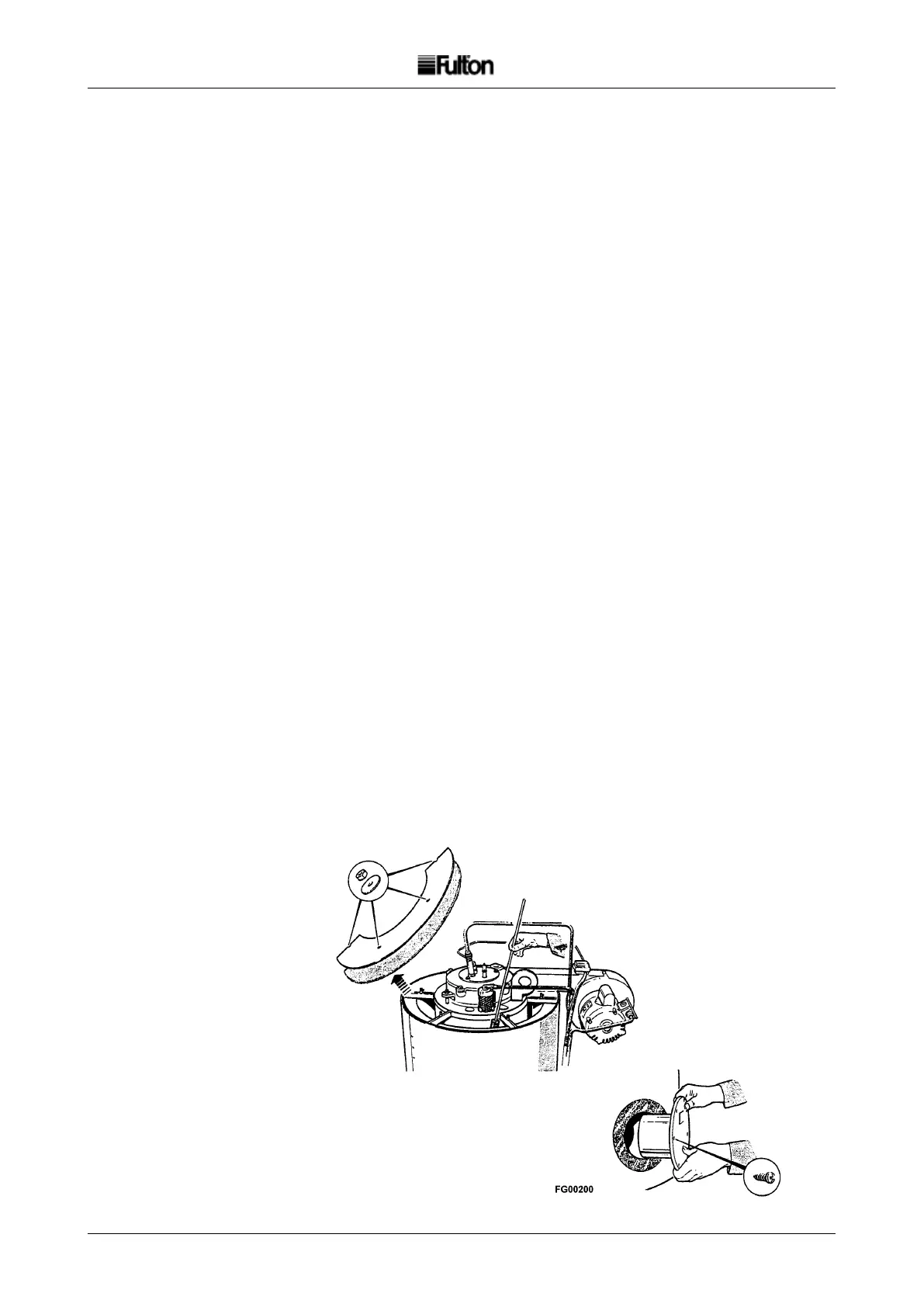

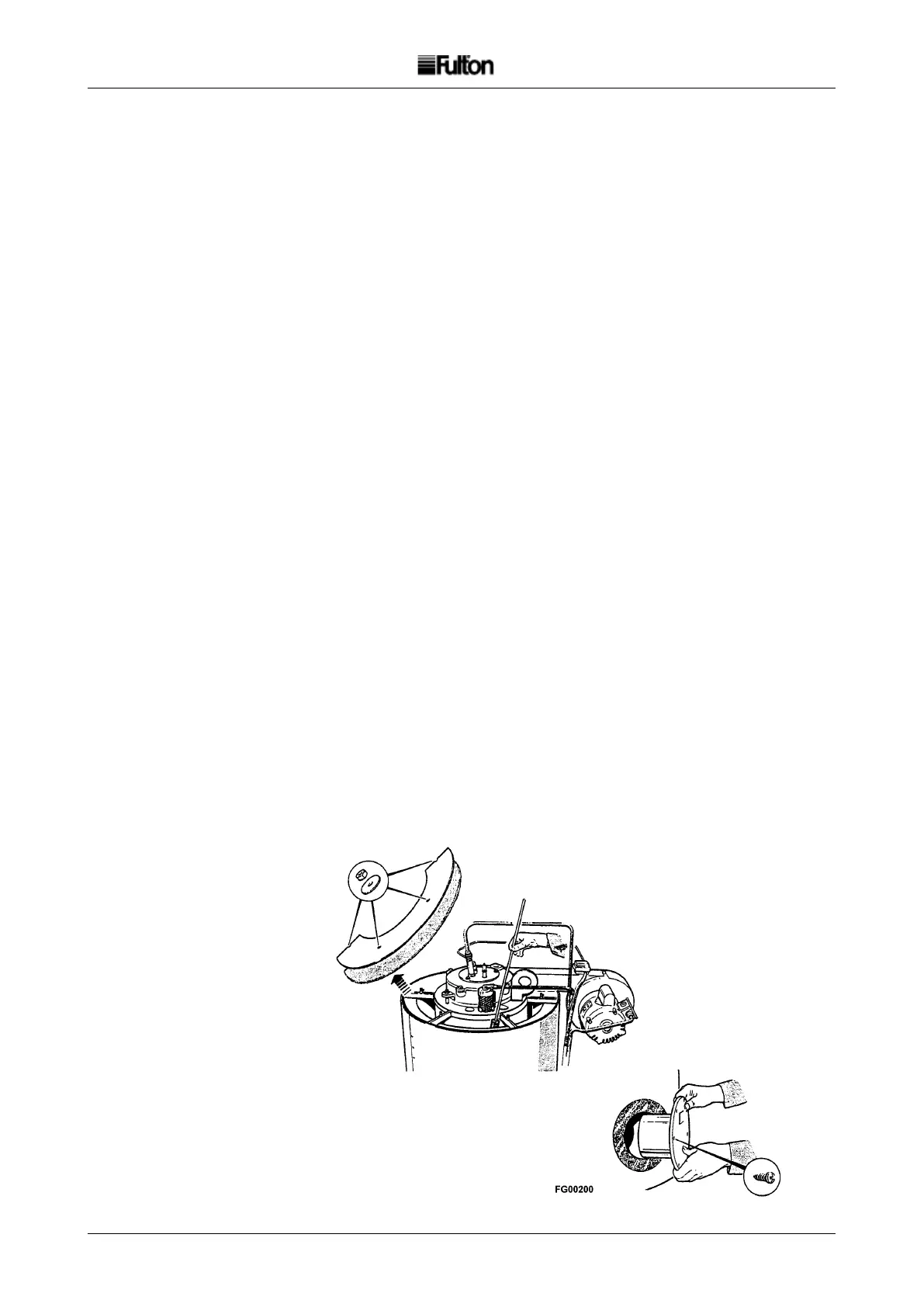

FIG. 20 FLUE CLEANING

Cleaning the Flues

Removethecleanoutdoortotheue

passes and to the bottom of the boiler.

36

4

Loading...

Loading...