J OIL-E-08 2008

2

11

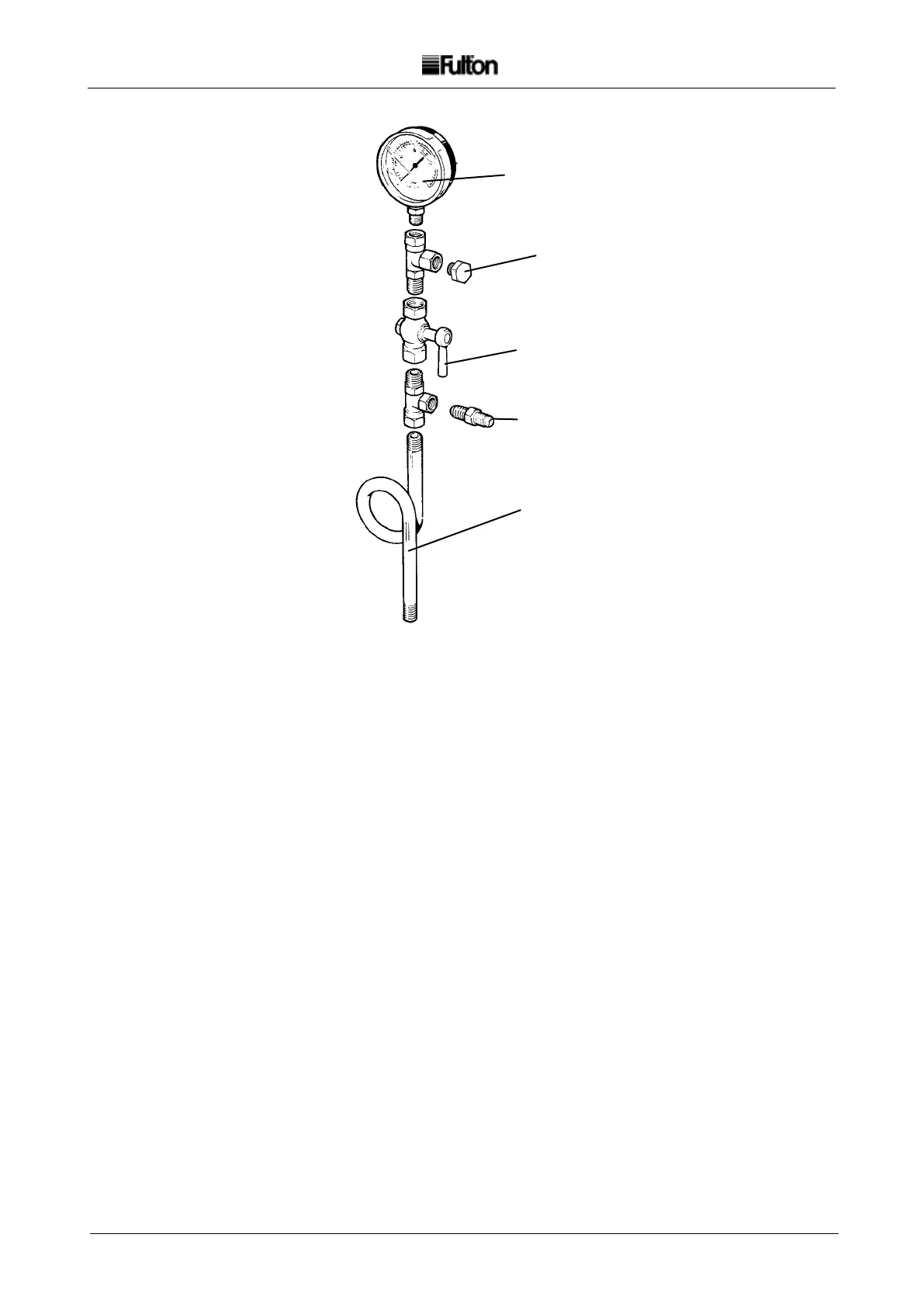

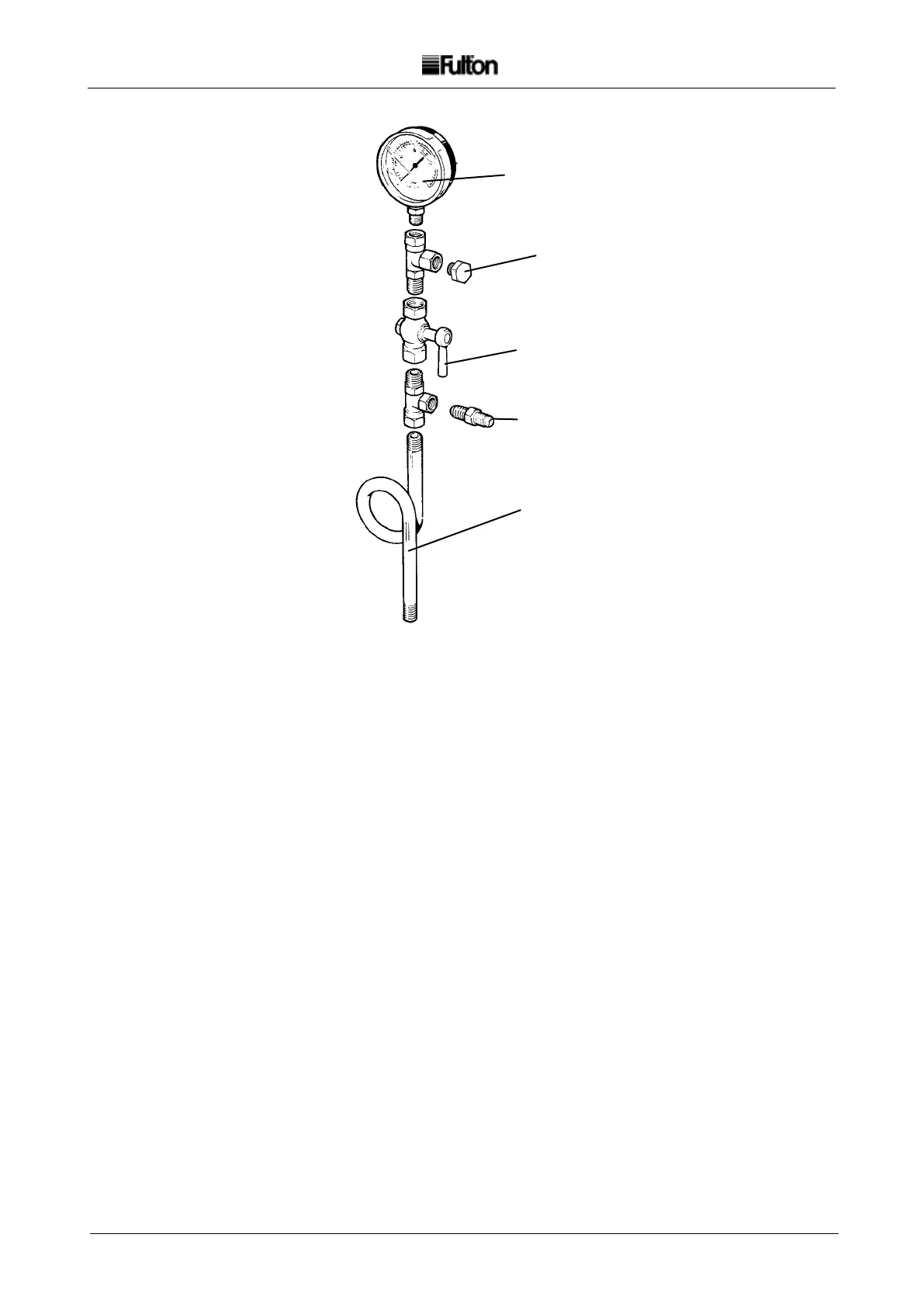

Steam Pressure Gauge

Steam Cock

Syphon

Plug

2.12 STEAM PRESSURE GAUGE

The steam pressure gauge assembly should be assembled in accordance with Fig. 9 using a suitable

sealant on all joints.

The gauge should be facing front towards the electrical control box and/or the operator of the boiler.

Screw the assembly into the top of the boiler and connect the copper tube from the pressure controller

located on the side of the control box to the nipple provided on the assembly.

FIG. 9 STEAM PRESSURE GAUGE

Test Point

2.16 COMMISSIONING THE BOILER

It is essential that the commissioning procedures listed below are carried out by a Fulton Service

Engineer who will have the necessary experience and testing equipment to ensure that the installation

isnotonlycorrect,butisoperatingsafelyandatoptimumefciency.

FLUE COMMISSIONING

Priortoinitialringoftheboiler,theuemustbecheckedforleaks.

This is done by BOTH of the following methods:

Visual Inspection

Checkjointsbetweenalluesectionsforqualityofseals.Wheretheuepassesthroughthe

structureofthebuildinguseyourjudgementastotheintegrityofthissectionoftheue.

Smoke Test

Withtheuecapped,thedrainstabilizerpipe(iftted)blankedandasmokegenerator

insertedintotheue,thereshouldbenosmokevisiblefromtheue.

If either of these tests fail or at any time during boiler operation, there is doubt about the

integrityoftheue,shutdowntheboilerandcontactFultonBoilerWorksImmediately.

2

Loading...

Loading...