6-4 A73F0EA

he following adjustment normally are not

attempted in the field. Only when replacing the

LCD Panel then adjust as a preparation.

4. White Balance Adjustment

*This adjustment is needed when reparing T-CON

CBA.

Purpose: To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

1. Operate the unit for more than 20 minutes.

2. Input the White Purity.

3. Set the color analyzer to the CHROMA mode and

bring the optical receptor to the center on the

LCD-Panel surface after zero point calibration as

shown above.

Note: The optical receptor must be set

perpendicularly to the LCD Panel surface.

4. [CVBS]

Enter the Service mode. Press [ -] button on the

remote control unit and select “C/D/S 1” mode.

[YUV]

Enter the Service mode. Press [ -] button on the

remote control unit and select “C/D/S 2” mode.

[RGB]

Enter the Service mode. Press [ -] button on the

remote control unit and select “C/D/S 3” mode.

5. [CVBS]----(APL 70%)

Press [6] button to select “DB 1(C/D/S 1)” for Blue

adjustment. Press [4] button to select “DR 1(C/D/S

1)” for Red adjustment. When “x” value and “y”

value are not within specification, adjust “DB 1(C/

D/S 1)” or “DR 1(C/D/S 1)”. Refer to “1. Initial

Setting.”

[CVBS]----(APL 30%)

Press [3] button to select “COB 1(C/D/S 1)” for

Blue adjustment. Press [1] button to select “COR

1(C/D/S 1)” for Red adjustment. When “x” value

and “y” value are not within specification, adjust

“COB 1(C/D/S 1)” or “COR 1(C/D/S 1)”. Refer to

“1. Initial Setting.”

After adjusting (APL 30%), verify (APL 70%) again

and adjust repeatedly until both values are within

specification.

6. [YUV]----(APL 70%)

Press [6] button to select “DB 2(C/D/S 2)” for Blue

adjustment. Press [4] button to select “DR 2(C/D/S

2)” for Red adjustment. When “x” value and “y”

value are not within specification, adjust “DB 2(C/

D/S 2)” or “DR 2(C/D/S 2)”. Refer to “1. Initial

Setting.”

[YUV]----(APL 30%)

Press [3] button to select “COB 2(C/D/S 2)” for

Blue adjustment. Press [1] button to select “COR

2(C/D/S 2)” for Red adjustment. When “x” value

and “y” value are not within specification, adjust

“ CO B 2( C /D / S 2 ) ” o r “ C OR 2 (C / D /S 2) ” .

Refer to “1. Initial Setting.”

After adjusting (APL 30%), verify (APL 70%) again

and adjust repeatedly until both values are within

specification.

7. [RGB]----(APL 70%)

Press [6] button to select “DB 3(C/D/S 3)” for Blue

adjustment. Press [4] button to select “DR 3(C/D/S

3)” for Red adjustment.When “x” value and “y”

value are not within specification, adjust “DB 3(C/

D/S 3)” or “DR 3(C/D/S 3)”. Refer to “1. Initial

Setting.”

[RGB]----(APL 30%)

Press [3] button to select “COB 3(C/D/S 3)” for

Blue adjustment. Press [1] button to select “COR

3(C/D/S 3)” for Red adjustment. When “x” value

and “y” value are not within specification, adjust

“ CO B 3( C /D / S 3 ) ” o r “ C OR 3 (C / D /S 3) ” .

Refer to “1. Initial Setting.”

After adjusting (APL 30%), verify (APL 70%) again

and adjust repeatedly until both values are within

specification.

8. Turn the power off and on again.

Test Point Adj. Point Mode Input

Screen

[ -]

button

[CVBS]

C/D/S 1

[YUV]

C/D/S 2

[RGB]

C/D/S 3

White Purity

(APL 70%)

or

(APL 30%)

M. EQ. Spec.

Pattern Generator,

Color analyzer

(APL 70%)

x=

0.272 ± 0.03

,

y=

0.278 ± 0.03

(APL 30%)

x=

0.272 ± 0.01

,

y=

0.278 ± 0.01

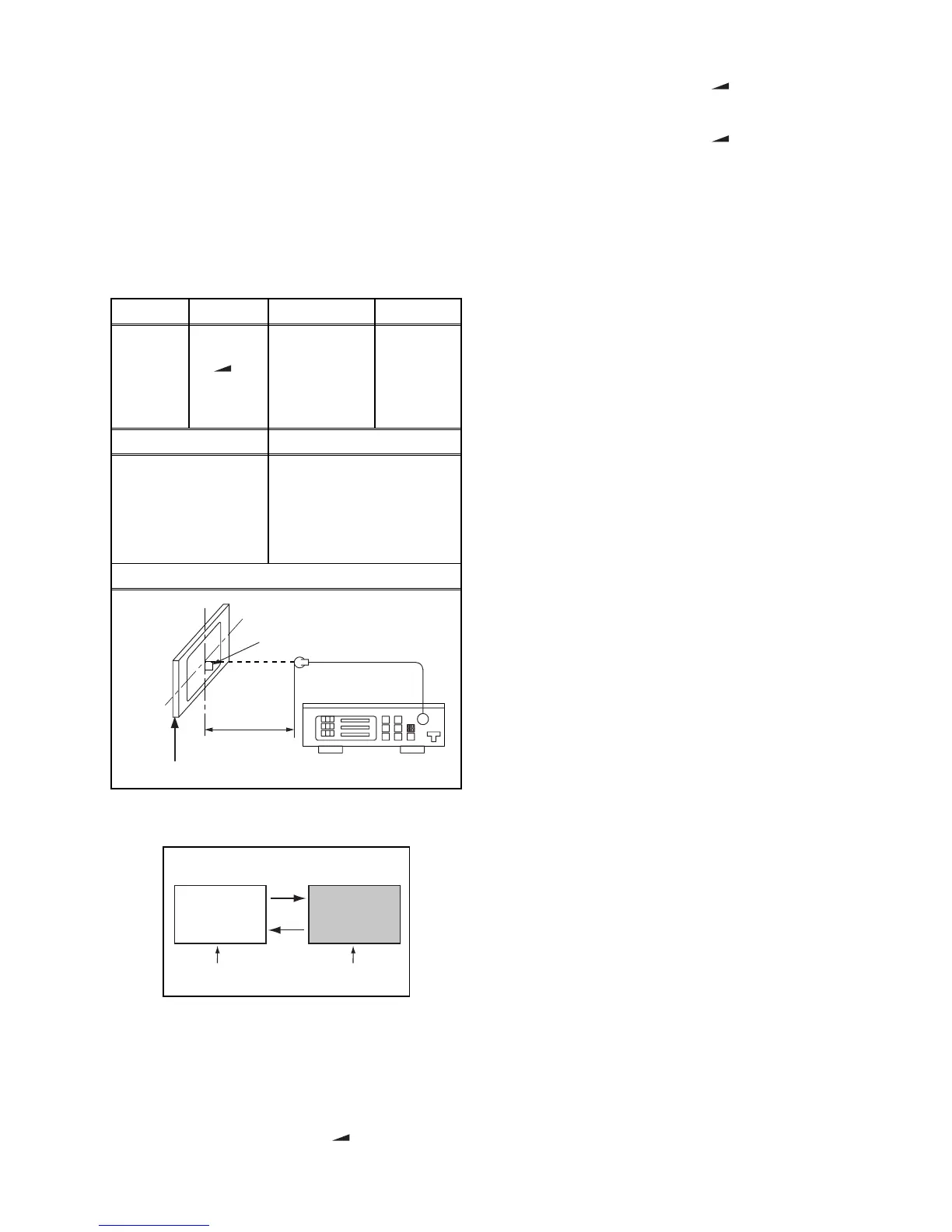

Figure

Color Analyzer

It carries out in a darkroom.

L = 3 cm

Perpendicularity

INPUT: WHITE 70%, 30%

30%=30IRE70%=70IRE

INPUT SIGNAL

Loading...

Loading...