• BEFORE USING

drain the battery pack very quickly. Make the

travel of each control mechanism somewhat

larger than the full stroke (including trim) of

the servo horn. Adjust the servo horns so that

they move smoothly even when the trim lever

and stick are operated simultaneously in the

same direction.

• Be alert for noise.

This set is noise-resistant, but not completely

immune to noise. The use of noiseless parts is

recommended.

•When installing the switch harness, cut a rec-

tangular hole slightly larger than the full stroke

of the switch and install the switch so that it

moves smoothly from ON to OFF. Also do this

when the switch is installed inside the fuselage

and is turned on and off from the outside with

a piece of wire. Install the switch where it will

not be exposed to engine oil or dust and dirt.

• Although the antenna appears to be too long,

do not cut it or fold it back.

• Install the servos securely. Tighten the mount-

ing screws until the rubber damper is crushed

slightly. If the screws are too tight, the cushion-

ing effect will be adversely effected.

• The crystal can be changed from the outside of

the receiver case. Always use the Futaba trans-

mitter/receiver matched crystal set to change

the band.

• The receiver that is used with the 7UAP and

7UAF is a dual conversion receiver. This re-

ceivers requires a special crystal so please order

the correct crystal set.

• Spare servo horns are supplied. Use them as

needed.

• Use extension cords matched to the model.

• Wrap the receiver in sponge rubber. Place it

inside a waterproof plastic bag and secure the

end of the bag with a rubber band. Do the

same with the airborne battery pack.

• Use the rubber bands wrapped around the re-

ceiver to hold the servo and switch leads.

• After installation and checking are complete,

perform a range check by collapsing the trans-

mitter antenna and extending the receiver

antenna to its full length and operating the

transmitter from a distance of 20 to 30 meters

from the receiver. The servos should operate

normally at this distance.

• Differs with the weather and surroundings.

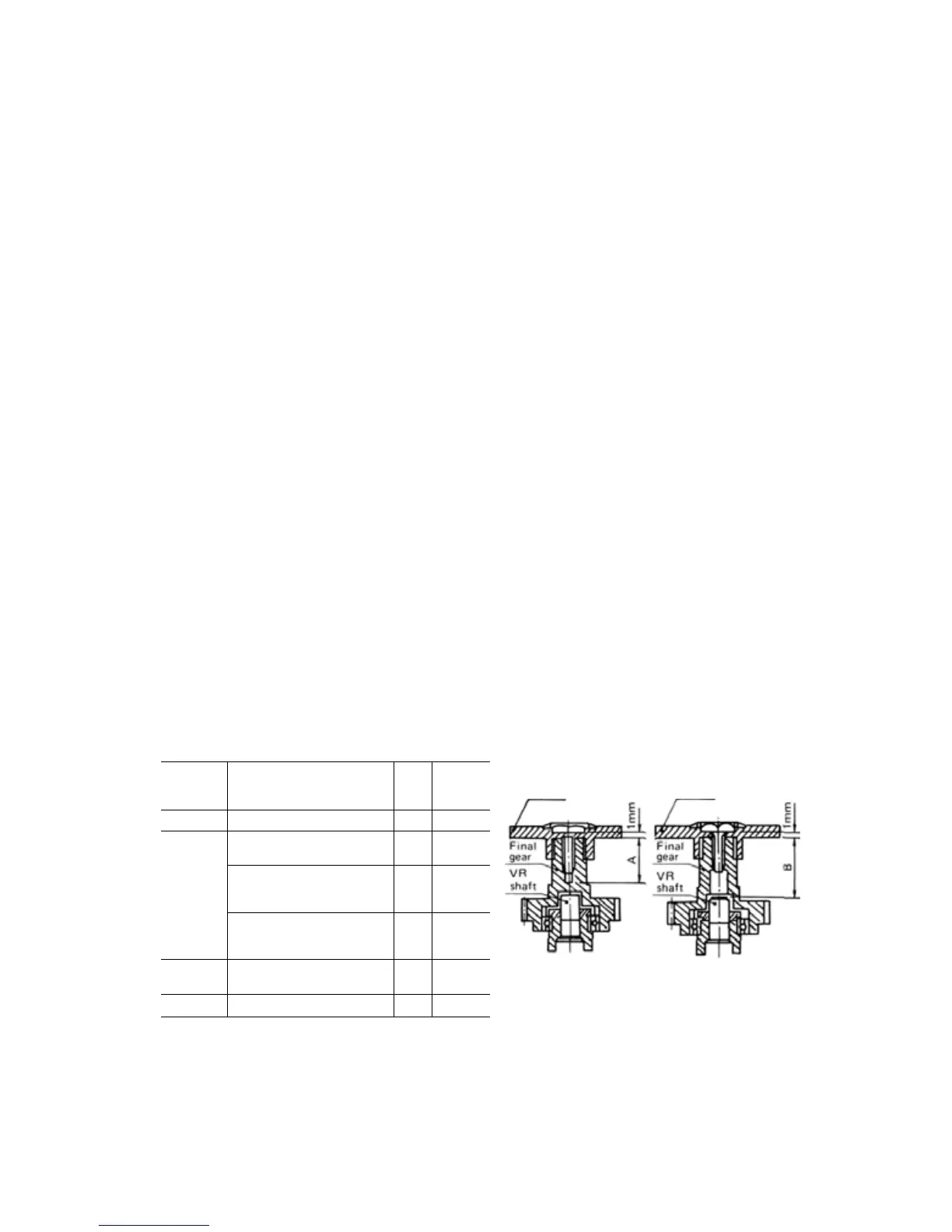

SERVO HORN MOUNTING SCREW PRECAUTIONS

Servo horn screws

Horn

mounting

screw size

2.6x6

2.6x8

2.6x10

2.6x12

Applicable servo

S133, S143 series

S 129 series

S130 series, S9101, S5101

S128 series

S132 series

S135 series, S9601

S136G

S138 series

S148 series

S131S series, S9201,S9301

89401

8134 series, 83301

Type

B

A

A

B

B

B

A

B

B

A

A

Dimen-

sions

(m/m)

5.7

7.9

7.9

11.9

7.3

8.7

9.0

9.9

10.5

9.0

11.3

Horn

Horn

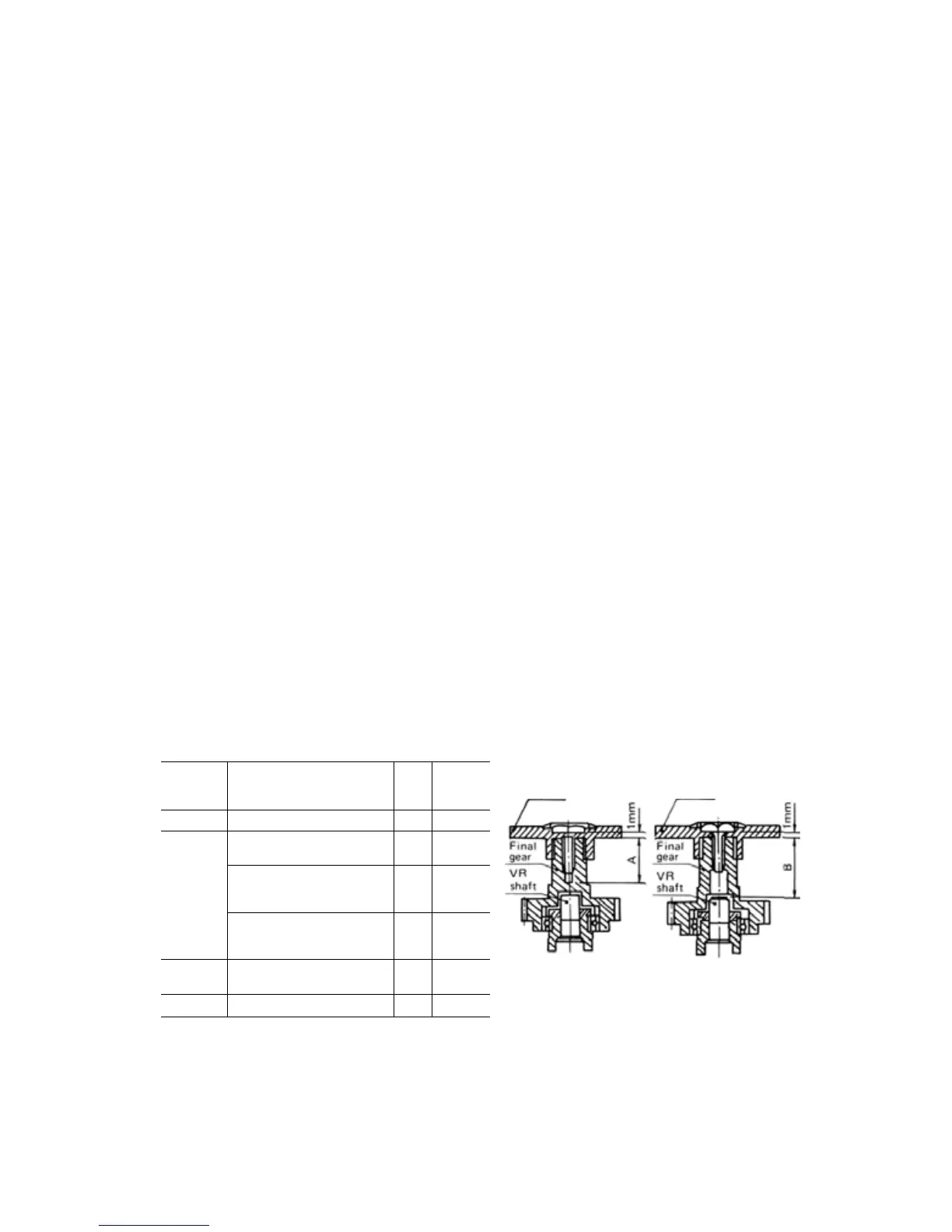

Waterproof type A Non-waterproof type B

Notes

• The screws are 2.6m/m tapping screws.

• If screws longer than necessary are used, the final gear may be broken or the potentiometer may be damaged or

may fall out.

-5-

Loading...

Loading...