-

-

-11--11-

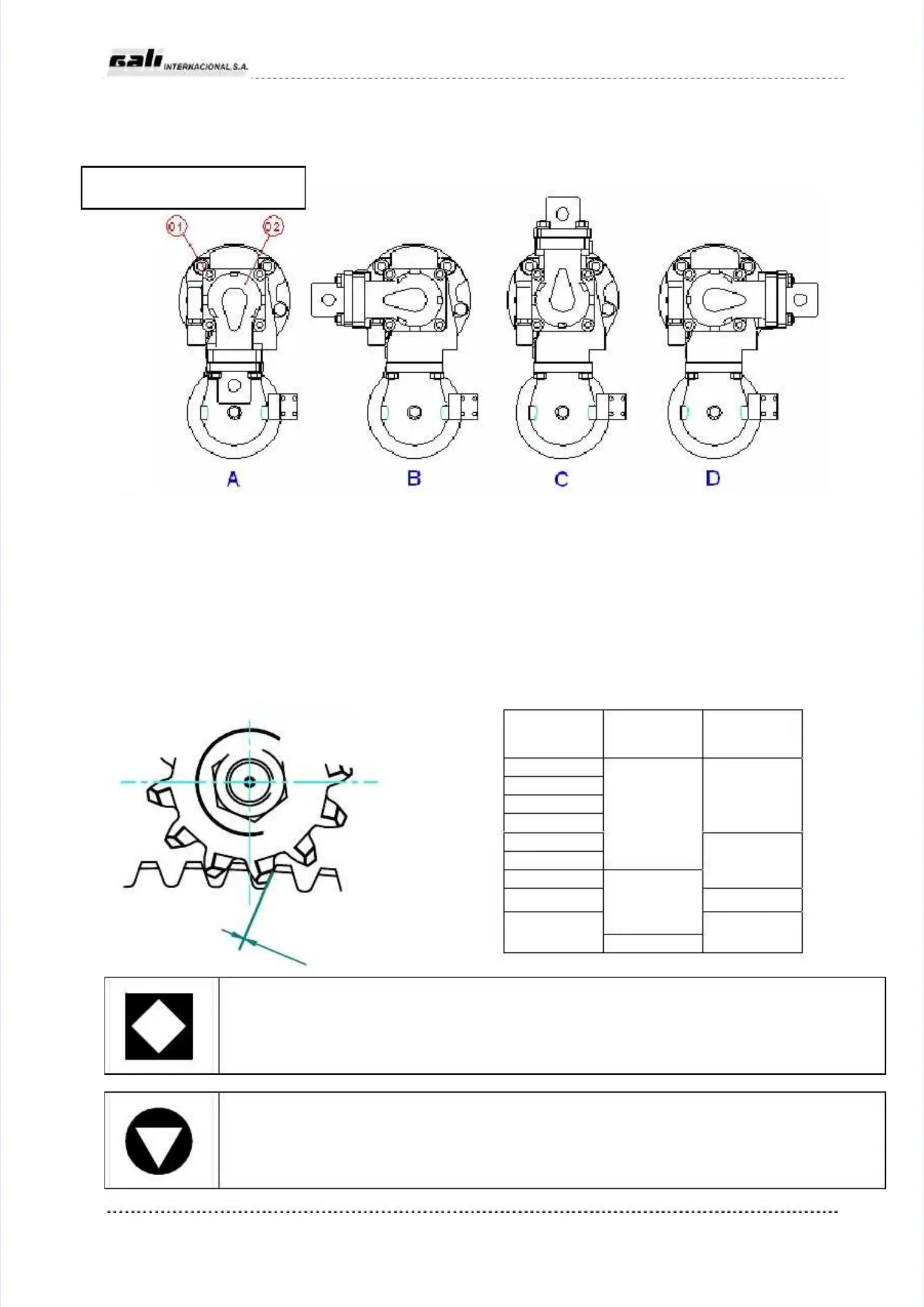

IndependIndependently of the assembly positions of tently of the assembly positions of the starter as a he starter as a whole with respect to the whole with respect to the motor, both the intakemotor, both the intake

nozzle and the exhaust silencer are directional, to facilitate their adaptation to the motor.nozzle and the exhaust silencer are directional, to facilitate their adaptation to the motor.

Four positions are possible, at 90º to each Four positions are possible, at 90º to each other, as indicated in the following figure:other, as indicated in the following figure:

If not specified otherwise, the position A If not specified otherwise, the position A is that delivered as standard.is that delivered as standard.

To change from one position to another, it is To change from one position to another, it is necessary to remove the four necessary to remove the four screws 01 and rotate the intakescrews 01 and rotate the intake

nozzle 02, taking care not to nozzle 02, taking care not to damage the O-ring that joins the two damage the O-ring that joins the two pieces and situate the flexible pipe in thepieces and situate the flexible pipe in the

most favourable posimost favourable position. Be careful to avoid the entry of dirt to tion. Be careful to avoid the entry of dirt to the interior of the starter. Replace the screws,the interior of the starter. Replace the screws,

applying a torque of 70 Nm.applying a torque of 70 Nm.

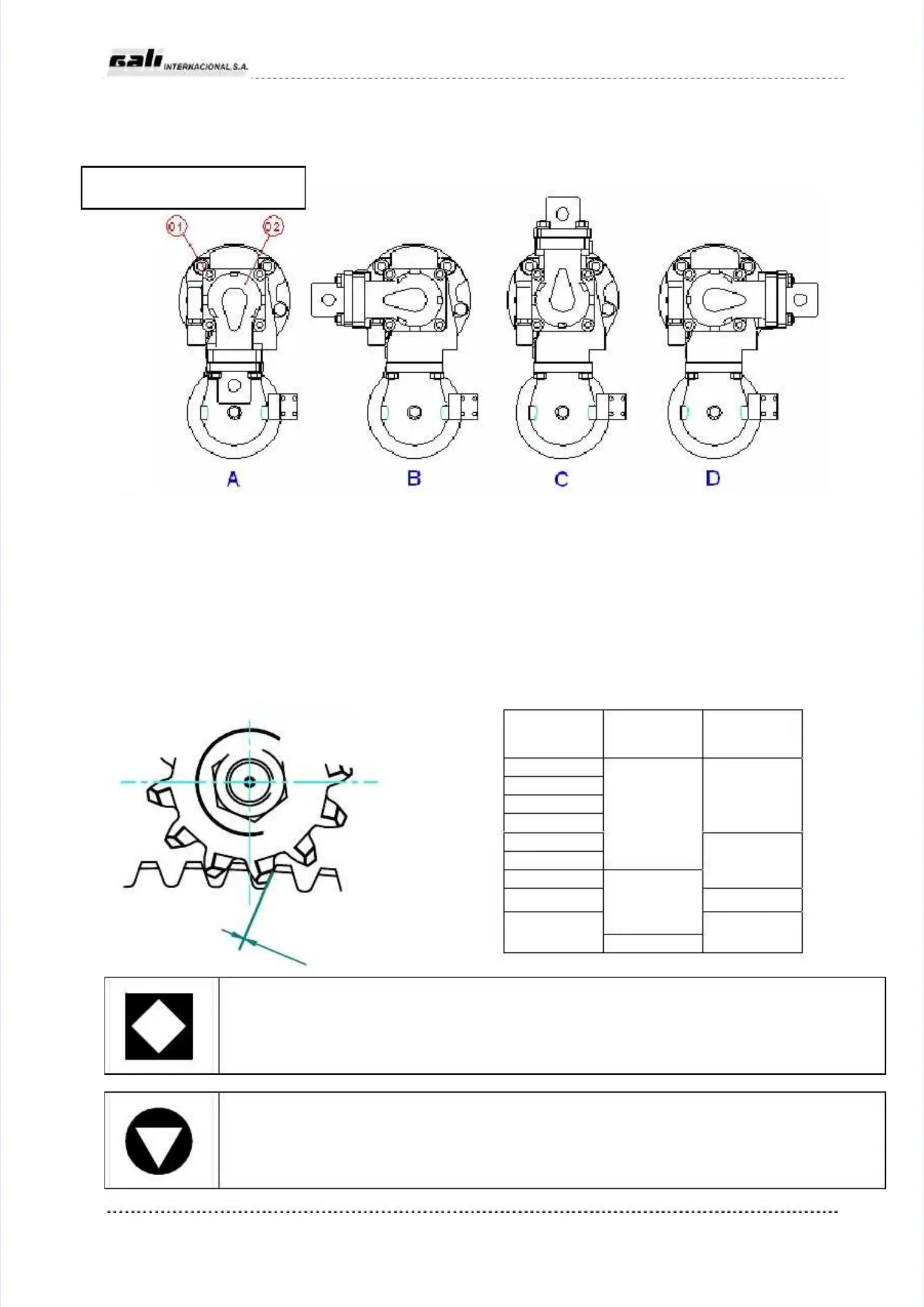

After fixed the starter to the engine:After fixed the starter to the engine:

It should be verified that tIt should be verified that there is adequate play between drive pinion and crown wheel, and that it is here is adequate play between drive pinion and crown wheel, and that it is constantconstant

over the length of the over the length of the tooth edge. Check if the front tooth edge. Check if the front distance of the gearing is that distance of the gearing is that indicated. Also respect theindicated. Also respect the

screw tightening torques of the screw tightening torques of the following diagram.following diagram.

JJ

nn

The starter has to be firmly joined to the motor body (not to the bed or The starter has to be firmly joined to the motor body (not to the bed or other attachedother attached

elements). To avoid vibrations between the starter and the connection pipe, the installation iselements). To avoid vibrations between the starter and the connection pipe, the installation is

recommenderecommended near the starter of d near the starter of a straight length of flexible pipe of a straight length of flexible pipe of at least 300 mm, whichat least 300 mm, which

complies with the regulations relative to complies with the regulations relative to pipes under pressure (97/23/EC).pipes under pressure (97/23/EC).

If it is If it is not possible to secure the starter to the body of the motor, make sure that in thenot possible to secure the starter to the body of the motor, make sure that in the

operation thereof no vibrations are operation thereof no vibrations are produced which affect the produced which affect the distance between the drive piniondistance between the drive pinion

and the crown wheel of the and the crown wheel of the motor flywheel.motor flywheel.

m m (DP) (DP) alfa alfa Jn Jn (mm)(mm)

2.540 (10)2.540 (10)

2.752.75

33

3.175 (8)3.175 (8)

0.3 – 0.60.3 – 0.6

3.53.5

4.233 (6)4.233 (6)

20º20º

33

0.4 – 0.70.4 – 0.7

3.5 3.5 0.7 0.7 - - 11

15º15º

2.117 (12)2.117 (12)

12º12º

0.3 – 0.50.3 – 0.5

4 SCREWS M124 SCREWS M12

TIGHTENING TORQUE 84 NmTIGHTENING TORQUE 84 Nm

Loading...

Loading...