-

-

-22--22-

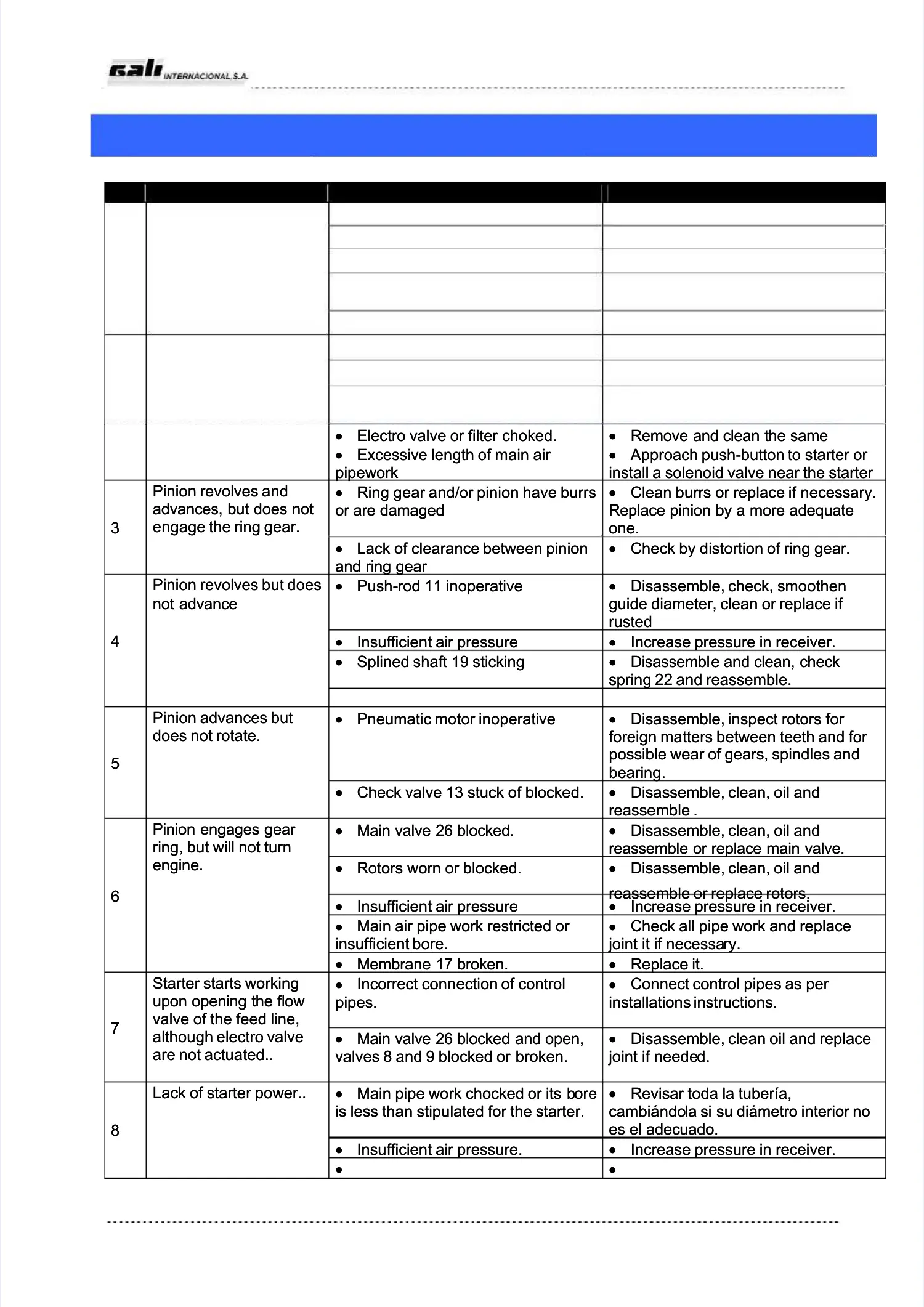

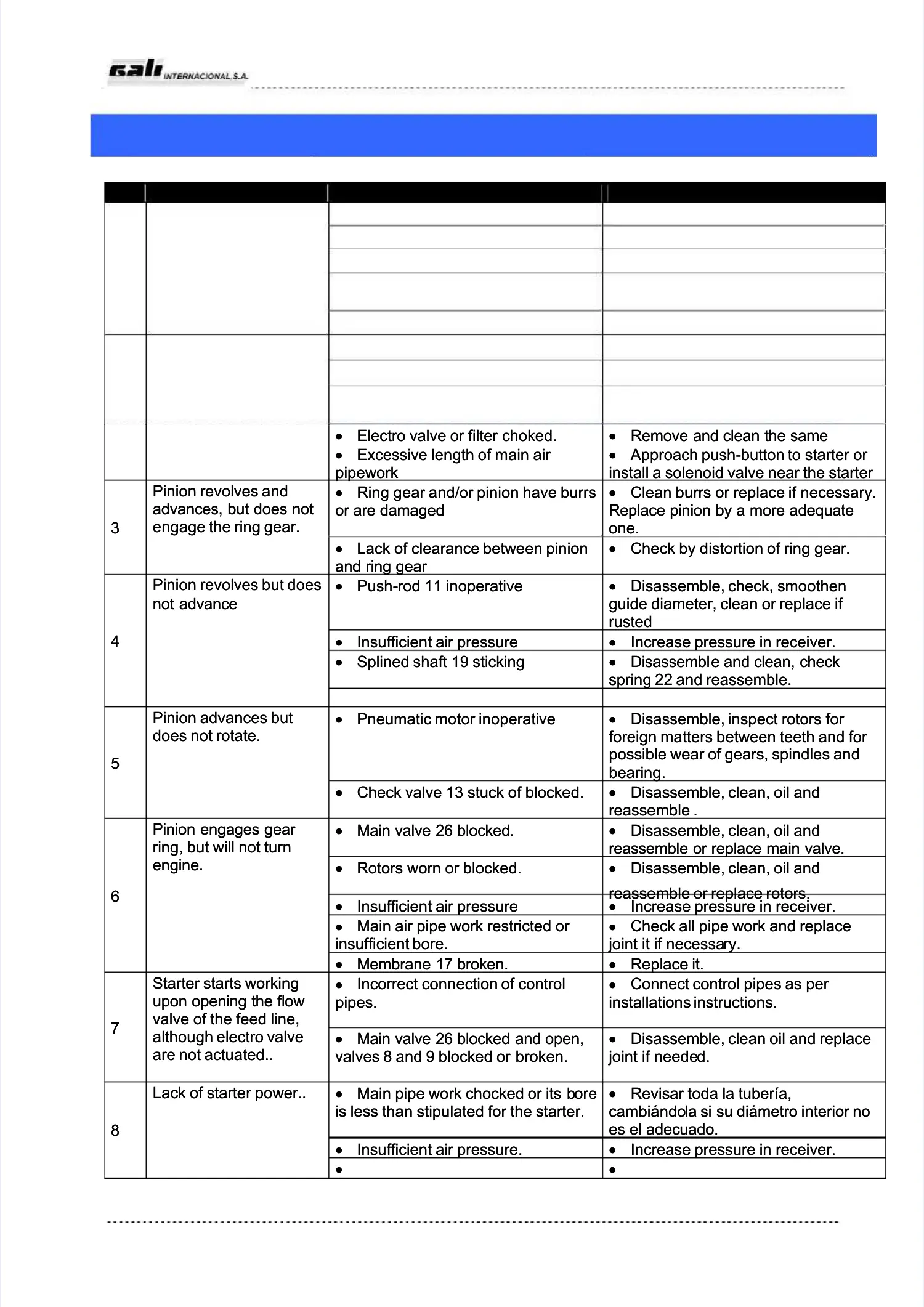

9. – CORRECTION OF POSSIBLE FAULTS9. – CORRECTION OF POSSIBLE FAULTS

FAILFAILURE URE POSIBLE POSIBLE CAUSE CAUSE CORRECTIONCORRECTION

Empty Empty air air receiver receiver (s)(s) Charge Charge receiver receiver (s)(s)

Flow Flow valve valve (s) (s) closed.closed. Open Open flow flow valve valve (s)(s)

Control Control circuit circuit blocked.blocked. Disconnect Disconnect and and clean clean outout

There There is is not not signal signal for thfor the e electroelectro

valvevalve

Control Control signalsignal

11

On pressing push-On pressing push-

button, starter does notbutton, starter does not

respond and not air flowrespond and not air flow

seems to exist in controlseems to exist in control

circuit.circuit.

Leak Leak in in control control duct. duct. .. Repair Repair or or replace.replace.

Insufficient Insufficient air air pressurepressure

Increase Increase pressure pressure in in receiverreceiver

Piston Piston 7 7 and and valve valve 8 8 sticking sticking inin

closed positionclosed position

Remove Remove and and check check both, both, smoothensmoothen

guides or change parts.guides or change parts.

22

On pressing push-On pressing push-

button, starter does notbutton, starter does not

respond, although airrespond, although air

flows through controlflows through control

circuitcircuit

Electro Electro valve valve or or filter filter choked.choked.

Excessive Excessive length length of of main main airair

pipeworkpipework

Remove Remove and and clean clean the the samesame

Approach Approach push-button push-button to to starter starter oror

install a solenoid valve near the starterinstall a solenoid valve near the starter

Ring Ring gear gear and/or and/or pinion pinion have have burrsburrs

or are damagedor are damaged

Clean Clean burrs burrs or or replace replace if if necessary.necessary.

Replace pinion by a more adequateReplace pinion by a more adequate

one.one.

33

Pinion revolves andPinion revolves and

advances, but does notadvances, but does not

engage the ring gear.engage the ring gear.

Lack Lack of of clearance clearance between between pinionpinion

and ring gearand ring gear

Check Check by by distortion distortion of of ring ring gear.gear.

Push-rod Push-rod 11 11 inoperativeinoperative Disassemble, Disassemble, check, check, smoothensmoothen

guide diameter, clean or replace ifguide diameter, clean or replace if

rustedrusted

Insufficient Insufficient air air pressurepressure

Increase Increase pressure pressure in in receiver.receiver.

Splined Splined shaft shaft 19 19 stickingsticking DisassemblDisassemble e and and clean, clean, checkcheck

spring 22 and reassemble.spring 22 and reassemble.

44

Pinion revolves but doesPinion revolves but does

not advancenot advance

Pneumatic Pneumatic motor motor inoperativeinoperative Disassemble, Disassemble, inspect inspect rotors rotors forfor

foreign matters between teeth and forforeign matters between teeth and for

possible wear of gears, spindles andpossible wear of gears, spindles and

bearing.bearing.

55

Pinion advances butPinion advances but

does not rotate.does not rotate.

Check Check valve valve 13 13 stuck stuck of of blocked.blocked.

Disassemble, Disassemble, clean, clean, oil oil andand

reassemble .reassemble .

Main Main valve valve 26 26 blocked.blocked.

Disassemble, Disassemble, clean, clean, oil oil andand

reassemble or replace main valve.reassemble or replace main valve.

Rotors Rotors worn worn or or blocked.blocked.

Disassemble, Disassemble, clean, clean, oil oil andand

reassemble or replace rotors.reassemble or replace rotors.

Insufficient Insufficient air air pressurepressure Increase Increase pressure pressure in in receiver.receiver.

Main Main air air pipe pipe work work restricted restricted oror

insufficient bore.insufficient bore.

Check Check all all pipe pipe work work and and replacereplace

joint it if necessajoint it if necessary.ry.

66

Pinion engages gearPinion engages gear

ring, but will not turnring, but will not turn

engine.engine.

Membrane Membrane 17 17 broken.broken.

Replace Replace it.it.

Incorrect Incorrect connection connection of of controlcontrol

pipes.pipes.

Connect Connect control control pipes pipes as as perper

installations instructions.installations instructions.

77

Starter starts workingStarter starts working

upon opening the flowupon opening the flow

valve of the feed line,valve of the feed line,

although electro valvealthough electro valve

are not actuated..are not actuated..

Main Main valve valve 26 26 blocked blocked and and open,open,

valves 8 and 9 blocked or valves 8 and 9 blocked or broken.broken.

Disassemble, Disassemble, clean clean oil oil and and replacereplace

joint if needejoint if needed.d.

Main Main pipe pipe work work chocked chocked or or its bits boreore

is less than stipulated for the starter.is less than stipulated for the starter.

Revisar Revisar toda toda la la tubería,tubería,

cambiándocambiándola si la si su diámetro interior nosu diámetro interior no

es el adecuado.es el adecuado.

Insufficient Insufficient air air pressure.pressure. Increase Increase pressure pressure in in receiver.receiver.

88

Lack of starter power..Lack of starter power..

Badly Badly worn worn rotors.rotors.

Replace. Replace.

Loading...

Loading...