-

-

-19--19-

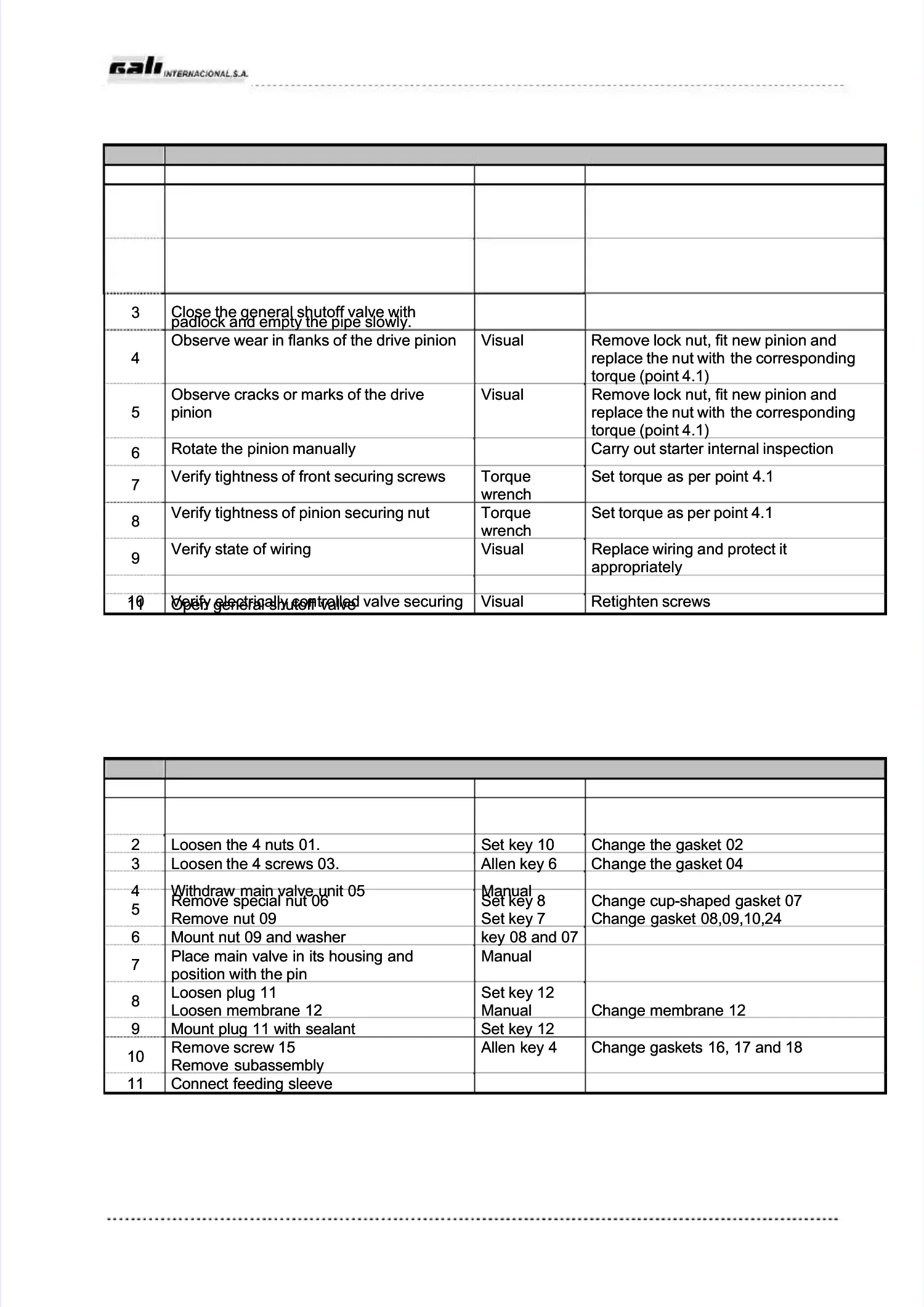

8.2.1. - MONTHLY REVISION8.2.1. - MONTHLY REVISION

GENERAL REVISION OF INSTALLATIONGENERAL REVISION OF INSTALLATION

AcActiti on on to to carcarry ry ouout t TooTools ls In tIn the evenhe even t ot of df defecefectt

11

Observe if there are leaks in theObserve if there are leaks in the

installation.installation.

Close the Close the correspondincorresponding general shutoffg general shutoff

valve, empty the pipe and replacevalve, empty the pipe and replace

deteriorated element.deteriorated element.

22

Observe Observe if if there there are are cracks cracks in in flexible flexible pipe pipe Visual Visual Close Close the the correspondincorresponding g general general shutoffshutoff

valve, empty the pipe and replace flexiblevalve, empty the pipe and replace flexible

pipe.pipe.

33

Close the general shutoff valve withClose the general shutoff valve with

padlock and empty the pipe slowly.padlock and empty the pipe slowly.

44

Observe Observe wear wear in in flanks flanks of of the the drive drive pinion pinion Visual Visual Remove Remove lock lock nut, nut, fit fit new new pinion pinion andand

replace the nut with replace the nut with the correspondingthe corresponding

torque (point 4.1)torque (point 4.1)

55

Observe cracks or marks of the driveObserve cracks or marks of the drive

pinionpinion

Visual Visual Remove Remove lock lock nut, nut, fit fit new new pinion pinion andand

replace the nut with replace the nut with the correspondingthe corresponding

torque (point 4.1)torque (point 4.1)

66

Rotate Rotate the the pinion pinion manually manually Carry Carry out out starter starter internal internal inspectioninspection

77

Verify Verify tightness tightness of of front front securing securing screws screws TorqueTorque

wrenchwrench

Set torque as per point 4.1Set torque as per point 4.1

88

Verify Verify tightness tightness of of pinion pinion securing securing nut nut TorqueTorque

wrenchwrench

Set torque as per point 4.1Set torque as per point 4.1

99

Verify Verify state state of of wiring wiring Visual Visual Replace Replace wiring wiring and and protect protect itit

appropriatelyappropriately

10 10 Verify Verify electrically electrically controlled controlled valve valve securing securing Visual Visual Retighten Retighten screwsscrews

11 11 Open Open general general shutoff shutoff valvevalve

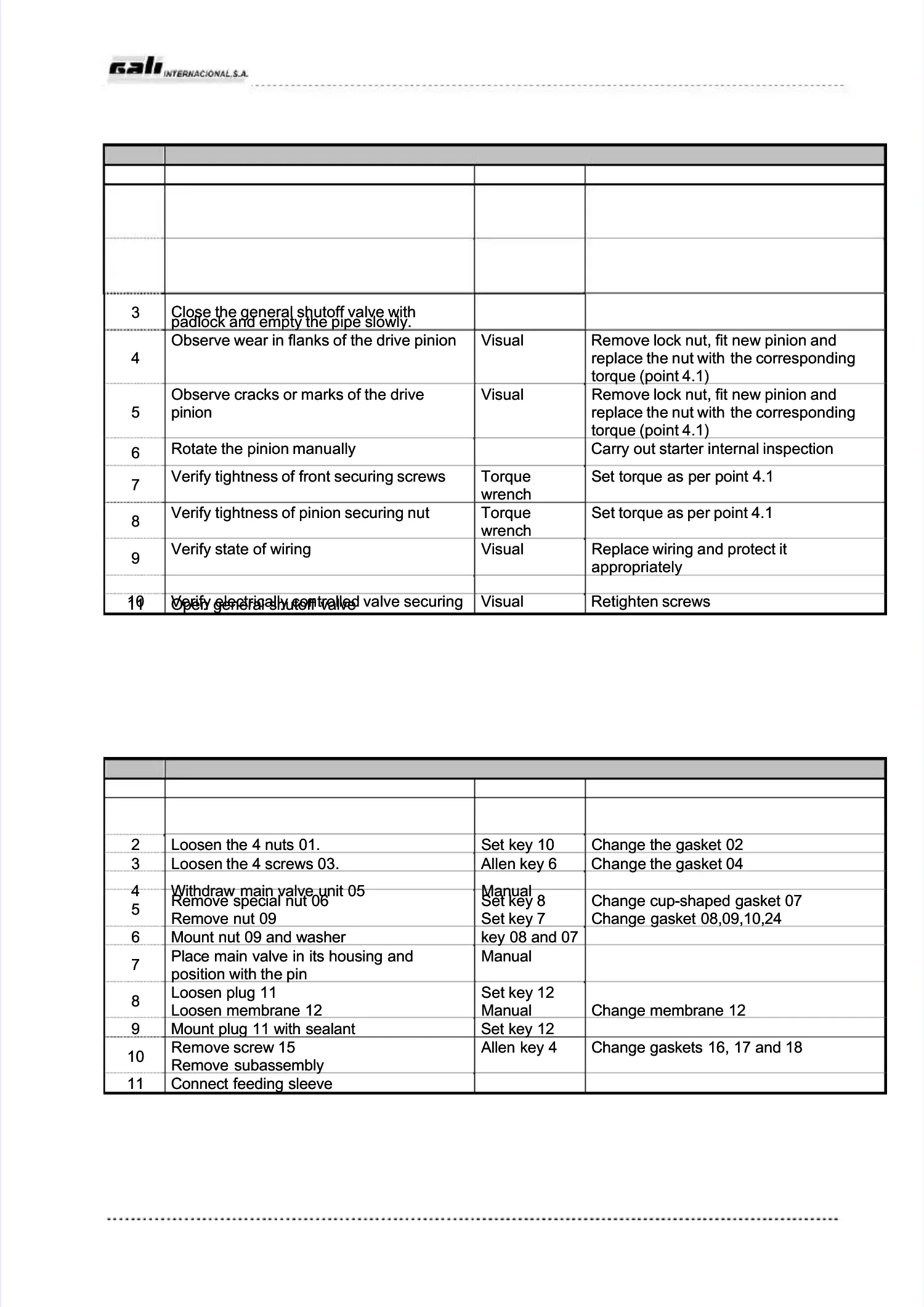

8.2.2. - ANNUAL REVISION

8.2.2. - ANNUAL REVISION

-GENERAL REVISION: CHANGE OF SETS -GENERAL REVISION: CHANGE OF SETS OF GASKETSOF GASKETS

Be sure to have at hand a set of seals ref. Be sure to have at hand a set of seals ref. 52904015290401

GENERAL REVISION: CHANGE OF SETS OF GASKETSGENERAL REVISION: CHANGE OF SETS OF GASKETS

AcActiti on on to to carcarry ry ouout t TooTools ls In tIn the evenhe even t ot of df defecefectt

11

Close the general shutoff valve withClose the general shutoff valve with

padlock and empty the pipe.padlock and empty the pipe.

2 2 Loosen Loosen the the 4 4 nuts nuts 01. 01. Set Set key key 10 10 Change Change the the gasket gasket 0202

3 3 Loosen Loosen the the 4 4 screws screws 03. 03. Allen Allen key key 6 6 Change Change the the gasket gasket 0404

4 4 Withdraw Withdraw main main valve valve unit unit 05 05 ManualManual

55

Remove special nut 06Remove special nut 06

Remove nut 09Remove nut 09

Set key 8Set key 8

Set key 7Set key 7

Change cup-shaped gasket 07Change cup-shaped gasket 07

Change gasket 08,09,10,24Change gasket 08,09,10,24

6 6 Mount Mount nut nut 09 09 and and washer washer key key 08 08 and and 0707

77

Place main valve in its housing andPlace main valve in its housing and

position with the pinposition with the pin

ManualManual

88

Loosen plug 11Loosen plug 11

Loosen membrane 12Loosen membrane 12

Set key 12Set key 12

Manual Manual Change Change membrane membrane 1212

9 9 Mount Mount plug plug 11 11 with with sealant sealant Set Set key key 1212

1010

Remove screw 15Remove screw 15

Remove subassemblyRemove subassembly

Allen Allen key key 4 4 Change Change gaskets gaskets 16, 16, 17 17 and and 1818

11 11 Connect Connect feeding feeding sleevesleeve

Loading...

Loading...