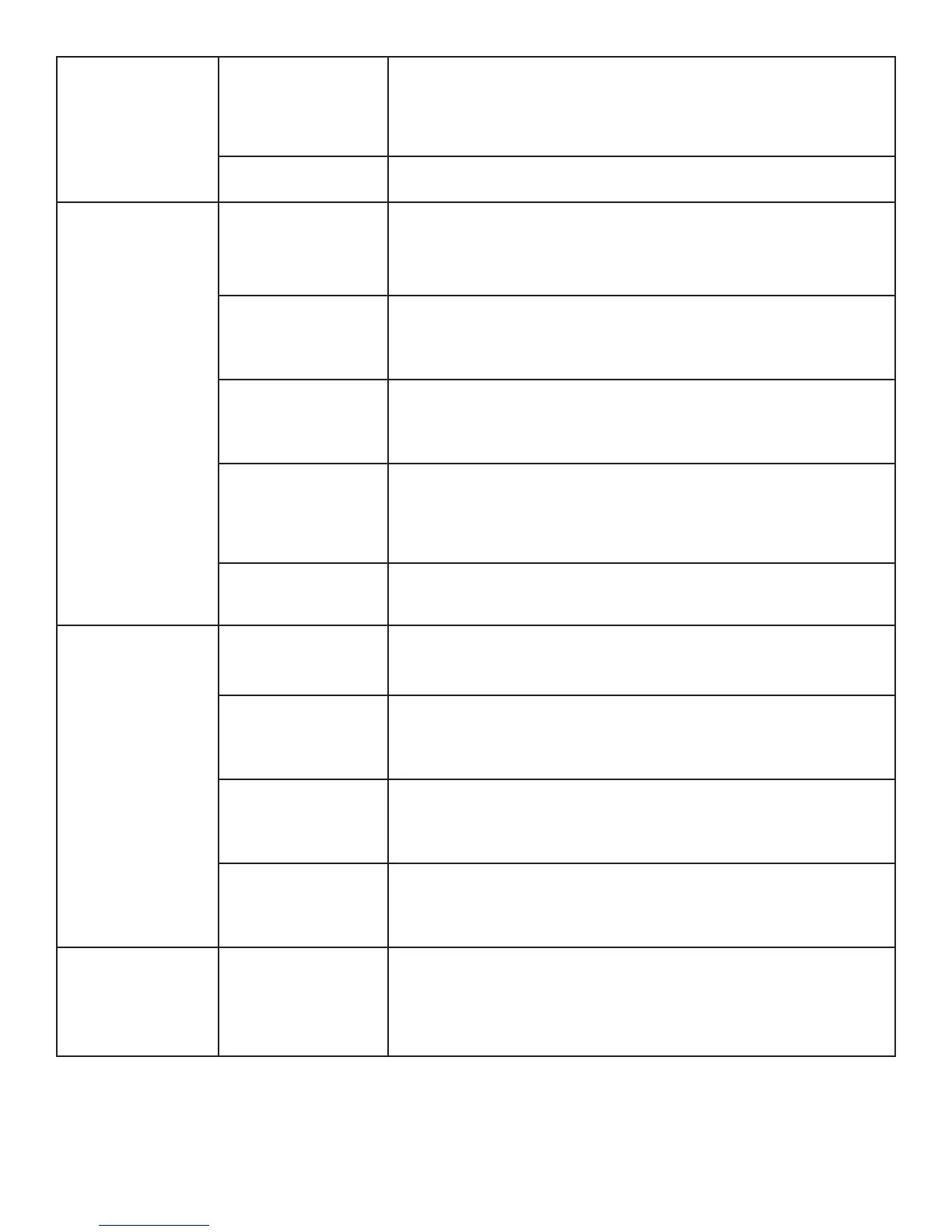

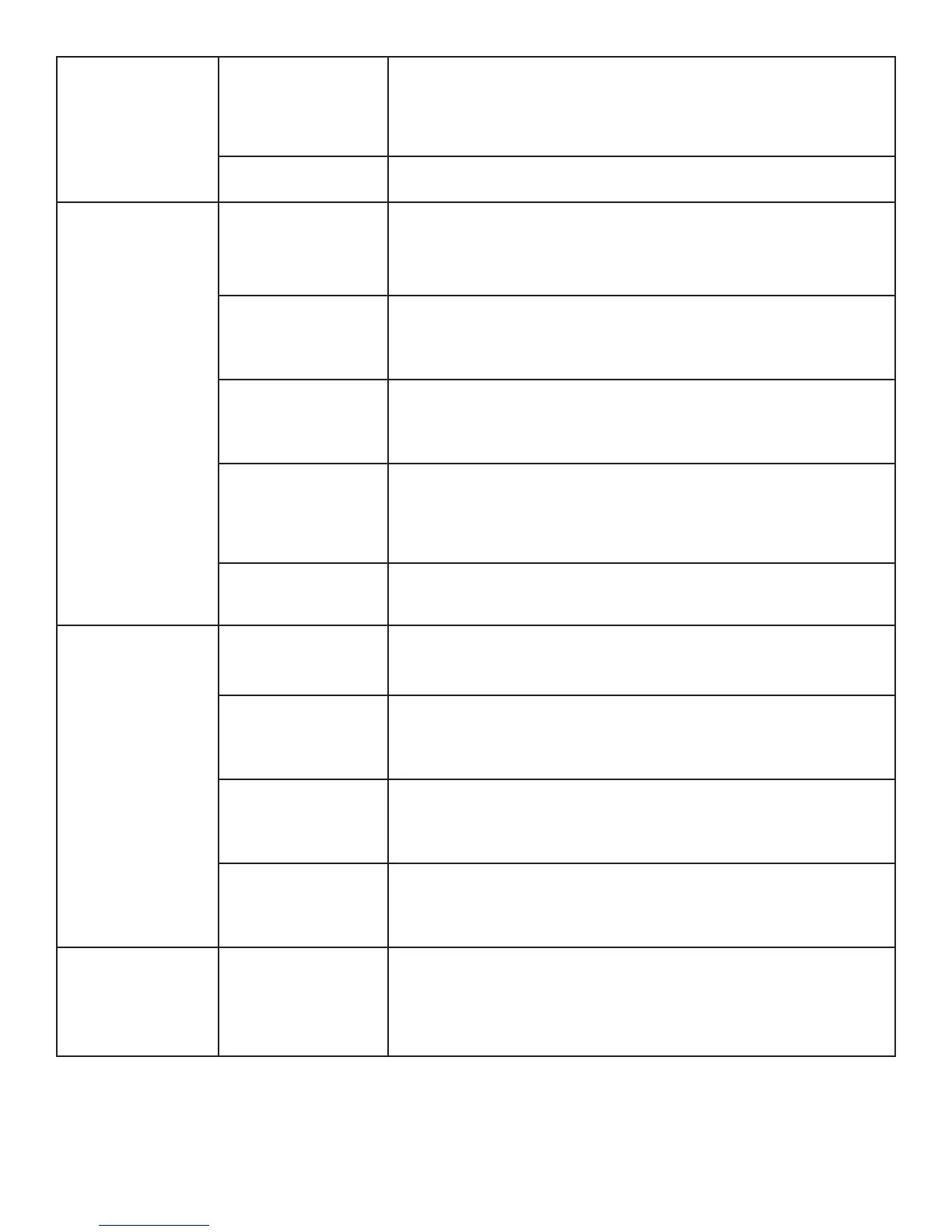

5

Bender consistently

develops over bends

Braking resistor on P.C.

board is malfunctioning.

Unplug bender power cord. Perform resistance measurements on braking

resistor. Remove chassis from rear of bender. Attach ohm meter across to

brown and gray wires.

If meter reads above 11 ohms, replace resistor.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

P.C. board circuit is

malfunctioning.

Remove and replace P.C. Board, Part Number- EC2006 or HC12.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Bender does not stop

at selected bend angle.

Bender is incorrectly

set up.

Ensure bender angle adjustment and zero adjustment has been performed.

This is required after every re-assembly.

Refer to “ZERO SET ADJUSTMENT” section (page 10) for mechanical

adjustment instructions. Refer to Instruction Sheet for Angle Adjustment

instructions and correct set up instructions.

Bend limit switch is not

being actuated by shoe

post.

Remove shoe indicator plate. Observe the tabs as they pass the bend limit

switch.

Adjust switch until tabs correctly contact the posts.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Bend limit switch is

malfunctioning.

Unplug the bender power cord. Attach leads to orange and green wires at the

switch. Continuity should exist. Push the actuator tab (on the switch).

Continuity should be broken. If not, replace the switch.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Braking resistor is

malfunctioning.

Unplug the bender power cord. Perform resistance measurement on braking

resistor. Attach leads across terminals.

A 9-11 ohms (+ 1 ohm) resistance is normal. Other readings are unacceptable.

Replace braking resistor, Part Number – RA19.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Brake circuit (P.C. board)

is malfunctioning.

If all other tests are positive, replace P.C. board, Part Number– EC2006

or HC12.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

During return function,

bender shoe does not

stop at zero point.

Plunger on return

limit switch is not

being tripped by the

trip ring tab.

Remove limit switch assembly. Observe tab to return limit switch contact.

If switch is not contacting tab, adjust switch position.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Bend limit switch is

malfunctioning.

If post to switch is correct, perform bend limit switch continuity check. Attach

leads to orange and green wires. Press limit switch tab.

Continuity should result. If not, replace switch.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Return limit switch is

malfunctioning.

Unplug the bender power cord. Perform return limit switch continuity check.

Attach leads to white and blue wires.

Continuity should be broken. If not, replace return limit switch.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Brake resistors are

malfunctioning.

Unplug the bender power cord. Perform resistance measurement on each

resistor. Place ohm meter leads on gray and brown wires.

Meter should read 9-11 ohms. If reading is over 11 ohms, replace resistor.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Bender shoe does not

stop rotating in both

the return and bend

directions.

Limit switches

assembled incorrectly

on the switch arm.

If the Limit Switch has been disassembled in the past, the switches may have

been reassembled incorrectly on the switch arm. The switch arm must have

two limit switches (blue face, facing away from arm) on the long side of the

arm, and one limit switch (black face, facing away from arm) on the short side

of the arm.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Loading...

Loading...