Chapter 2. Initial Setup

28 DigitalFlow™ Multipurpose Ultrasonic Liquid Flowmeter Startup Guide (1- and 2-Channel)

2.6.9 Reynolds Correction

11. Press [F1] to turn Reynolds Correction off, or [F2] to turn it on.

Note: Reynolds Correction is a number based on the Kinematic Viscosity and flow rate of the fluid. It should be

enabled for most applications.

12. When you enable the Reynolds Correction Factor, you must also enter the Kinematic Viscosity of your fluid, as

listed in Sound Speeds and Pipe Size Data. Use the numeric keys to enter a value, and press

[ENT].

2.6.10 Calibration Factor

13. Enter a value for the flow Calibration Factor and press [ENT]. The default value is 1.00, but values between 0.50

and 2.00 may be entered.

14. The menu now varies, depending on whether you have activated the TransFlection or Transit-Time mode.

• If you activated the TransFlection mode, the program asks for the Depth of Reflector. This setting determines where

in the pipe the DF868 looks for the reflected signal. The default value is 50%. Use the numeric keys to enter a

value, and press

[ENT].

Note: GE recommends activating the Reynolds Correction Factor when the Depth of Reflector is set at 50%. You can

disable the Reynolds Correction Factor when the Depth of Reflector is set at any other value.

• If you activated the Transit-Time mode, two steps appear.

a. Use the

[F1]-[F4] keys to select the desired Number of Traverses, the number of times the ultrasonic signal

traverses the pipe, from 1 to 5.

b. The Transducer Spacing prompt displays the spacing of the transducers, as calculated from the information you

have entered. Record this number and use it to properly space transducers.

Note: If necessary, you can overwrite the spacing shown (using the numeric keys) to match the actual physical

spacing of the transducers. The factory does not recommend overwriting the spacing. If you must, do not

change the spacing by more than ±10% from the value shown.

You have completed entering pipe parameters for clamp-on transducers. Press

[ENT] to return to the start of the PIPE

submenu, and [EXIT] to leave the submenu.

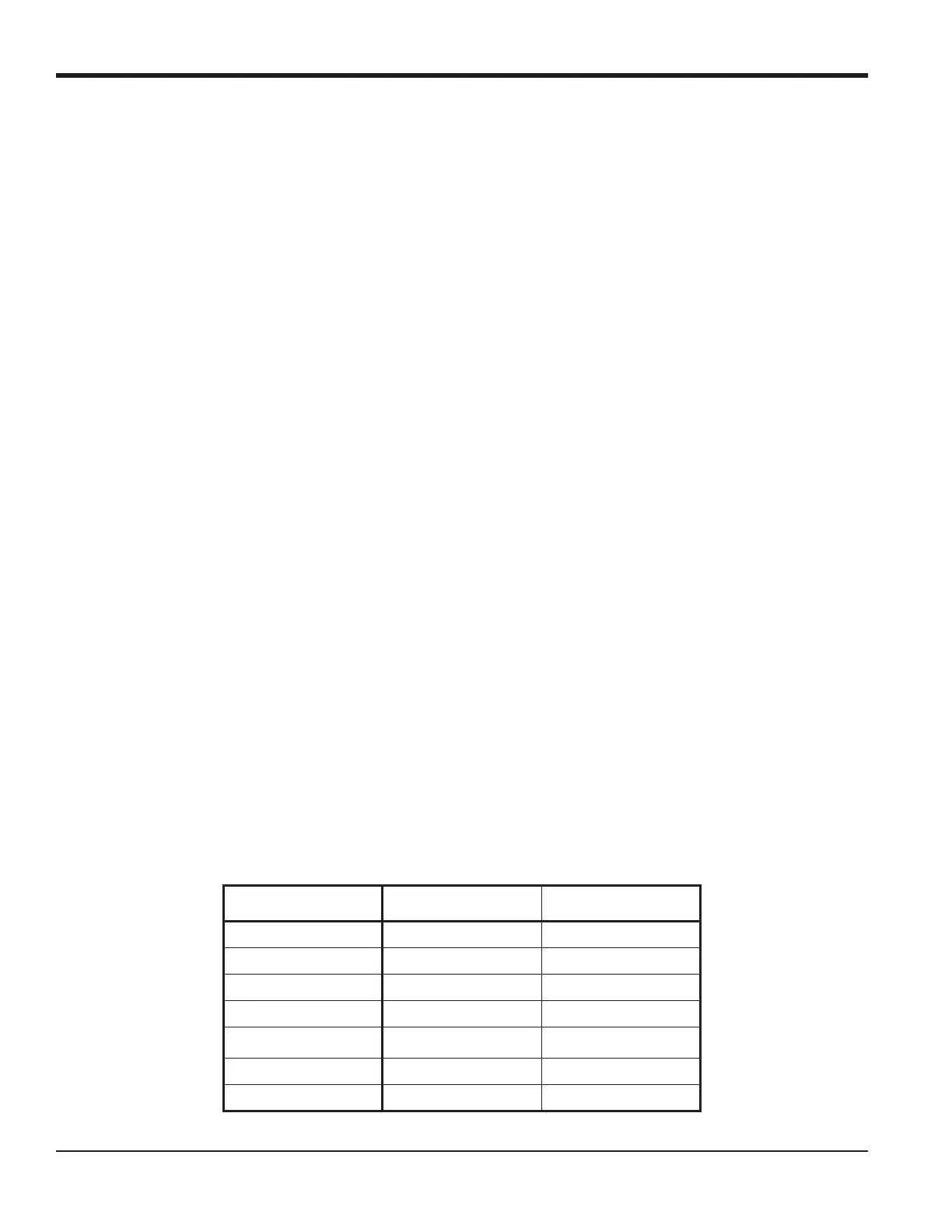

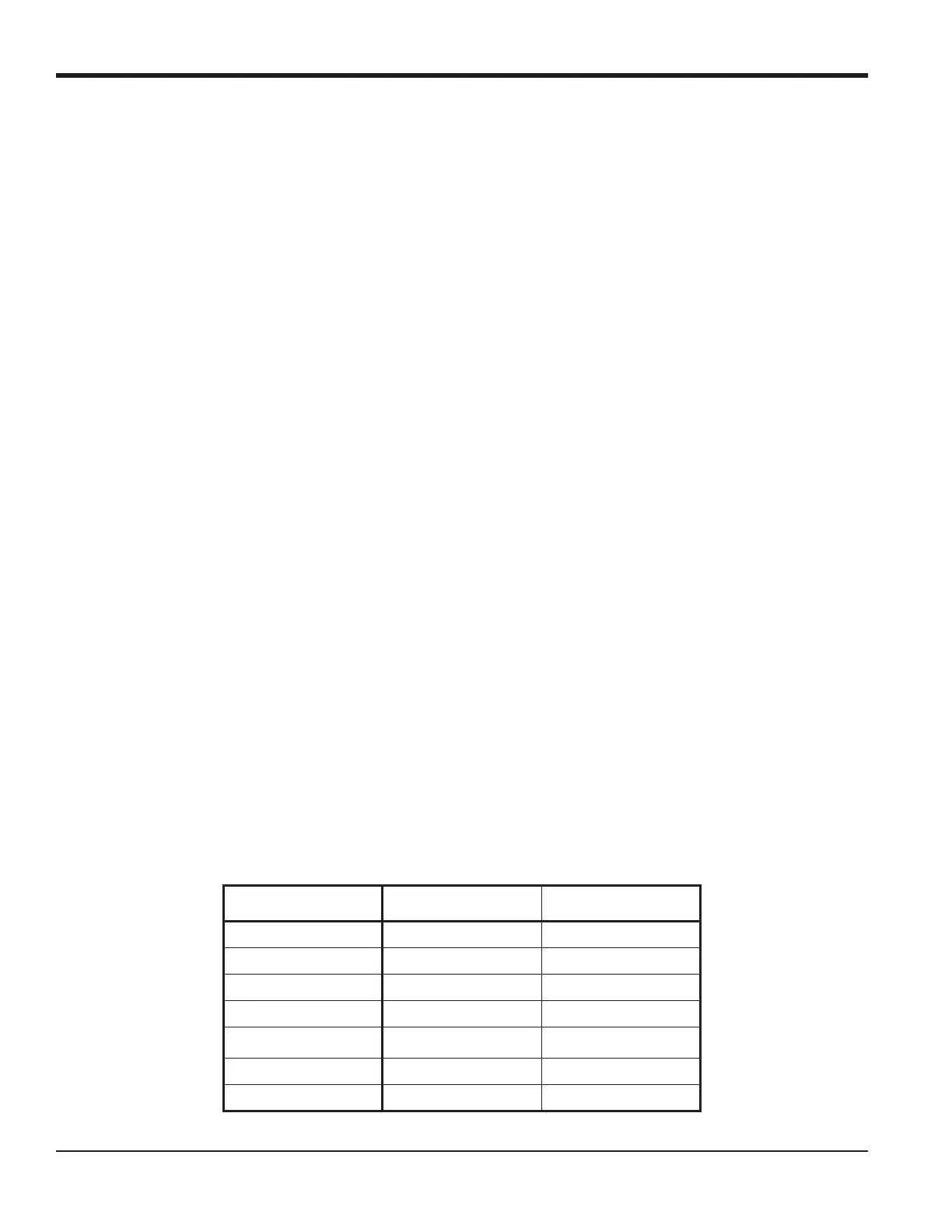

Table 12 lists the numeric parameters in the PIPE submenu, with their high and low limits.

Table 12: Low and High Limits for PIPE Parameters

Parameter Low Limit High Limit

Wedge Angle 25° 90°

Pipe OD 0.12 in. 300 in.

Pipe Wall 0 in. 4.0 in.

Lining Thickness 0 in. 4.0 in.

Kinematic Viscosity 0.1

10,000 (E-6 ft

2

/s)

Path Length 0.12 in. 480 in.

Axial Length 0.12 in. 480 in.

Loading...

Loading...