Do you have a question about the GE Kelman DGA900 and is the answer not in the manual?

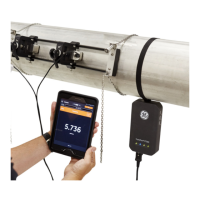

Overview of the Kelman DGA 900 system, its purpose, and features.

Defines the content and topics covered in this operator guide.

Describes the status indication of LEDs on the Hub module.

Explains safety symbols, warnings, and precautions.

Details technical specifications, including measurements and environmental ranges.

Lists standards and type tests the product meets.

Introduces the Human Machine Interface (HMI) and its access methods.

Explains how to establish HMI connection via Ethernet or USB.

Covers login procedures and different user roles.

Navigating the dashboard and using the Quick Access panel.

Accessing gas measurements, diagnostics, and active alarms.

Configuring gas ratios, relative saturation, and rate of change.

Setting up alarms for gases, ratios, and inputs.

Managing peripheral settings like analog and digital inputs.

Configuring communications, date/time, and firewall.

Covers firmware upgrades, sensor calibration, and factory settings.

Details TransOpto measurements, alarms, and settings.

Procedures for logging out and safely shutting down the device.

Explains error reporting, codes, and notifications.

Step-by-step guide for obtaining manual oil samples.

Overview of supported communication protocols like DNP3, IEC 61850, Modbus, HTTP/HTTPS.

GE Customer Service contact details for assistance.

Recommendations for securing remote operations and firewalls.

Instructions for removing and fitting the PGA lock for transport.

Procedures for battery replacement, filter cleaning, and cooler maintenance.

Explains time sync features and register formats.

General advice and procedures for setting gas level and ROC alarms.

| Power Supply | 100-240 V AC, 50/60 Hz |

|---|---|

| Ingress Protection | IP66 |

| Type | Dissolved Gas Analyzer |

| Gases Measured | Hydrogen (H2), Carbon Monoxide (CO), Carbon Dioxide (CO2), Methane (CH4), Ethane (C2H6), Ethylene (C2H4), Acetylene (C2H2), Oxygen (O2), Nitrogen (N2) |

| Communication Protocols | Modbus, DNP3, IEC 61850 |

| Measurement Method | On-line, continuous |

| Carrier Gas | Not required |

| Power Requirements | 100-240 VAC, 50/60 Hz |

| Dimensions | 600 mm x 500 mm x 400 mm |