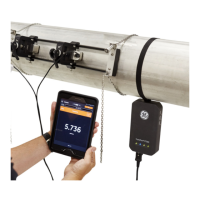

What to do if GE TransPort PT900 Measuring Instruments shows E4: Signal Quality error?

- SSean AndersenJul 28, 2025

If your GE Measuring Instruments displays an E4 error, it indicates that the peak of the upstream or downstream correlation signals has fallen below the programmed correlation peak limit, potentially due to a fluid, pipe, or electrical problem. To resolve this, check for sources of electrical interference. Verify the integrity of the tablet by temporarily using the PT900 on a test fluid/pipe that is known to be good. Also, inspect the transducers and relocate them if needed.