– 47 –

Troubleshooting

(Continued Next Page)

Problem Possible Cause and Repair

LCD display does not come on. The backlight connection on the main board may

not be secure. Check the connection to make sure it

is secure. The LCD backlight does not function below

30°F (-1.1°C). Test the inverter (see Inverter).

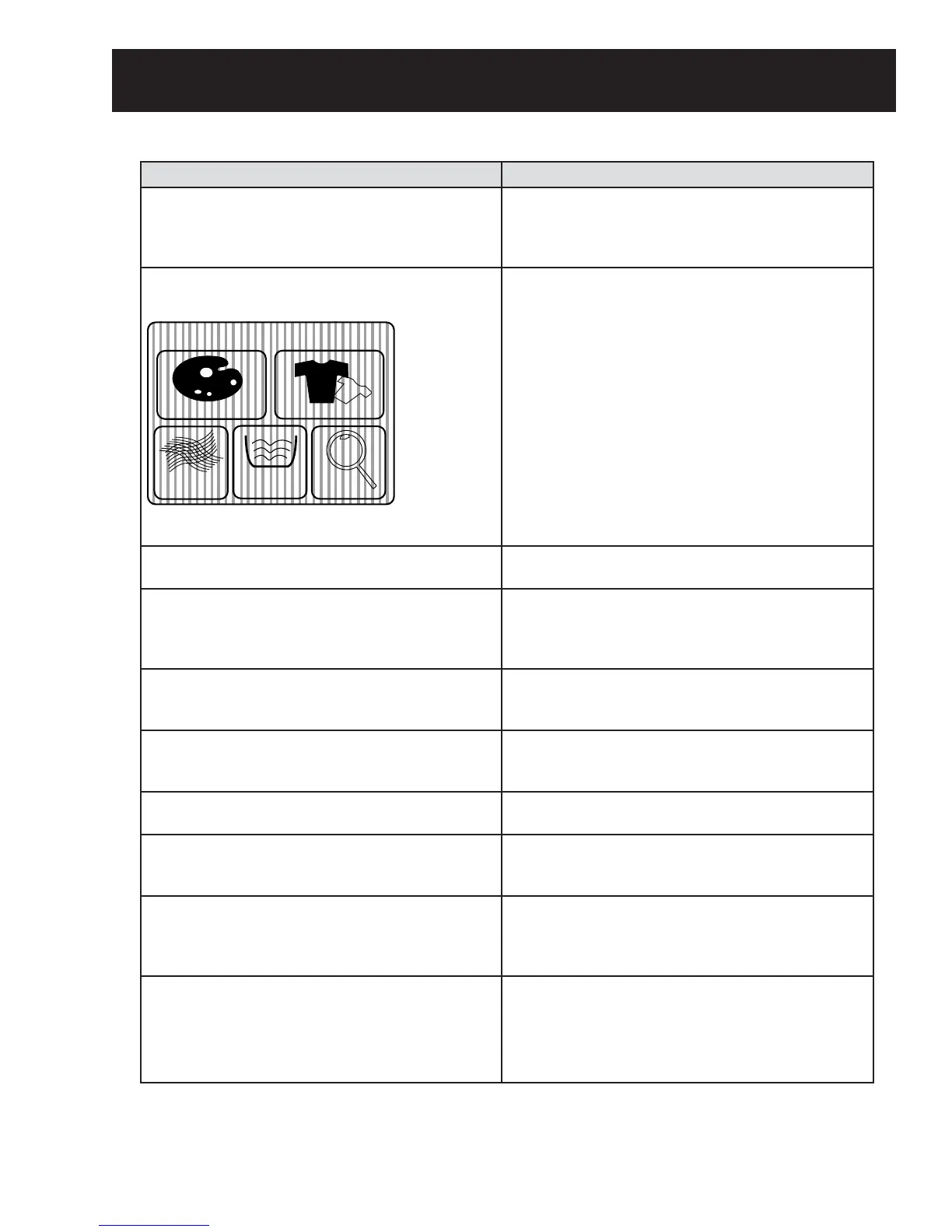

Vertical lines on the LCD display when the washer is

turned on.

GARMENT

FABRIC

SPECIAL

CYCLES

BY

BY

TOUCH TO SELECT WASH CYCLE

STAIN

INSPECTOR

COLOR

BY

Re-seat LCD ribbon cable at connector CN6 on the

main board. If necessary, a piece of Scotch tape may

be added to the back of the ribbon. This additional

thickness will provide better contact for the ribbon

terminals.

LCD screen too dark or too light as compared to LCD

dryer screen.

LCD refresh rate can be changed in Factory Test

Mode. (See Contrast setting.)

Replacement LCD screen too dark or too light. LCD

refresh rate is matched to inverter output at the

manufacturer.

Can occur when LCD screen is replaced. New LCD

screen must also be set to inverter output. Adjust

the refresh rate through the Factory Test Mode. (See

contrast setting.)

Touch screen pad activates an adjacent function

incorrectly, i.e. - Pressing one pad activates a

function of another pad.

The LCD display ribbon connection on the main board

may not be secure. Check the connection to make

sure it is secure.

Checkerboard pattern in MY CYCLES screen. Electrostatic discharge on main board. Enter MY

CYCLES and press DELETE on the touch screen LCD,

this will clear the checkerboard pattern.

Scuff marks on the plastic backsplash or cover

(Platinum models).

Can be removed by appliance polish, part no.

WR97X216 or a high quality of automotive paste wax.

Motor will not rotate in Demo Mode (motor pulses). On some models there is a software algorithm issue.

Add enough water to the tub so the pressure sensor

changes frequency.

“Frog” noise coming from inside the wash basket

when the washer is operating.

Pull out the infusor and check to see if the basket bolts

are rubbing on the bottom of the infusor. If so, use a

fi le and smooth out the rub spots on the bottom of the

infusor.

Water not shutting off at proper water level. The outer air chamber hole could be blocked due

to fl ashing that was left during production on some

models. Remove the pressure sensor hose and make

sure the fl ashing is gone and/or ream out the hole.

Run Pressure Sensor Test (see Pressure Sensor).

Loading...

Loading...