D

GB

F

E

I

Ru

13

96446-09.2020-DGbFEIRu

6 | Compressor assembly

Fig. 5

6.3 Pipeconnections

ATTENTION Damagepossible.

Superheatingcandamagethevalve.

Removethepipesupportsfromthevalveforsoldering.

Onlysolderusinginertgastoinhibitoxidationproducts(scale).

Thedischargegasconnectioncanbemovedupwardswithan

adapter(accessory).Thismakesiteasiertoremovethecom-

pressorfromarefrigeratingsystem.

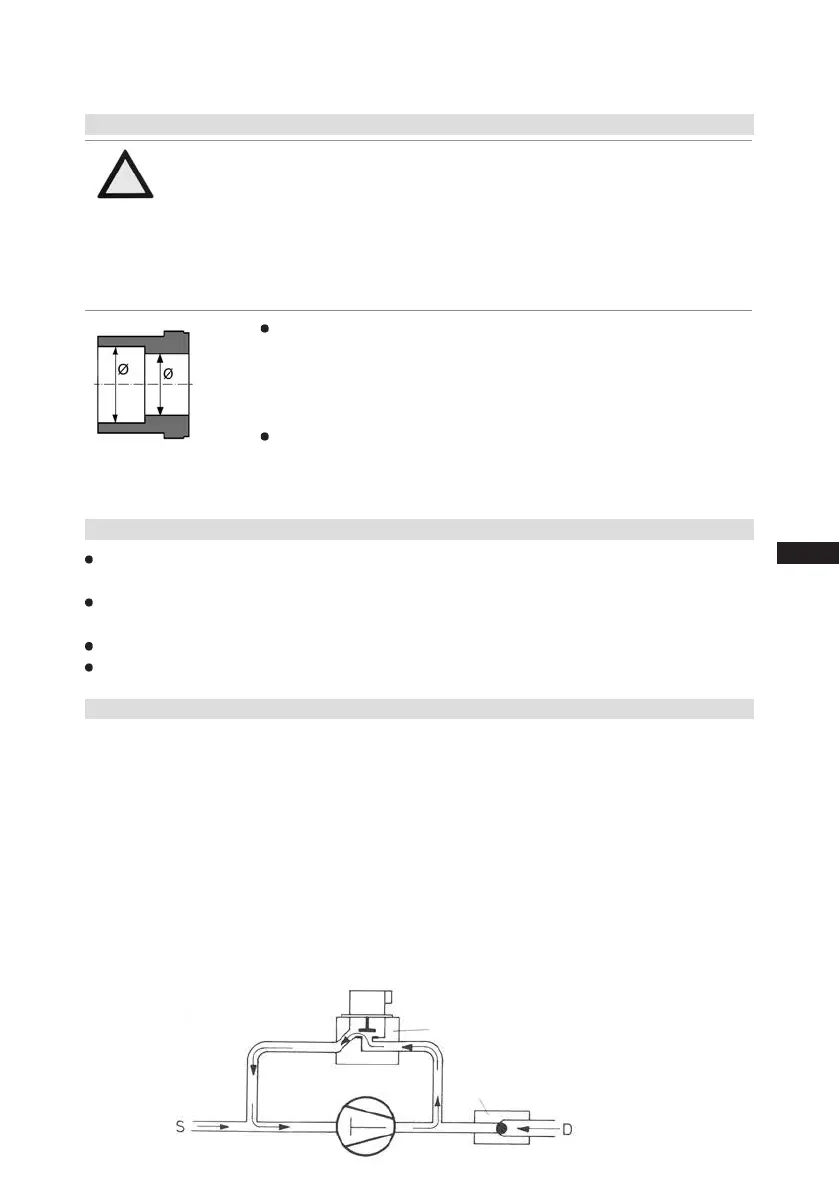

Fig. 4: graduated

internal diameter

Pipe connections on the compressor are available for soldering or

welding (accessories). The dischargeandsuctionlinevalves have

graduated inside diameters so that pipes with standard millimetre and

inch dimensions can be used. The pipe will be immersed more or less

deeply according to dimension.

The connection diameters of the shut-off valves are rated for maximum

compressor output. Theactualrequiredpipecrosssectionmustbe

matchedtotheoutput.Thesameappliesfornon-returnvalves.

6.4 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

6.5 Startunloader(external)

A internal start unloader ex factory is not available. Alternatively a start unloader can be installed in

the plant.

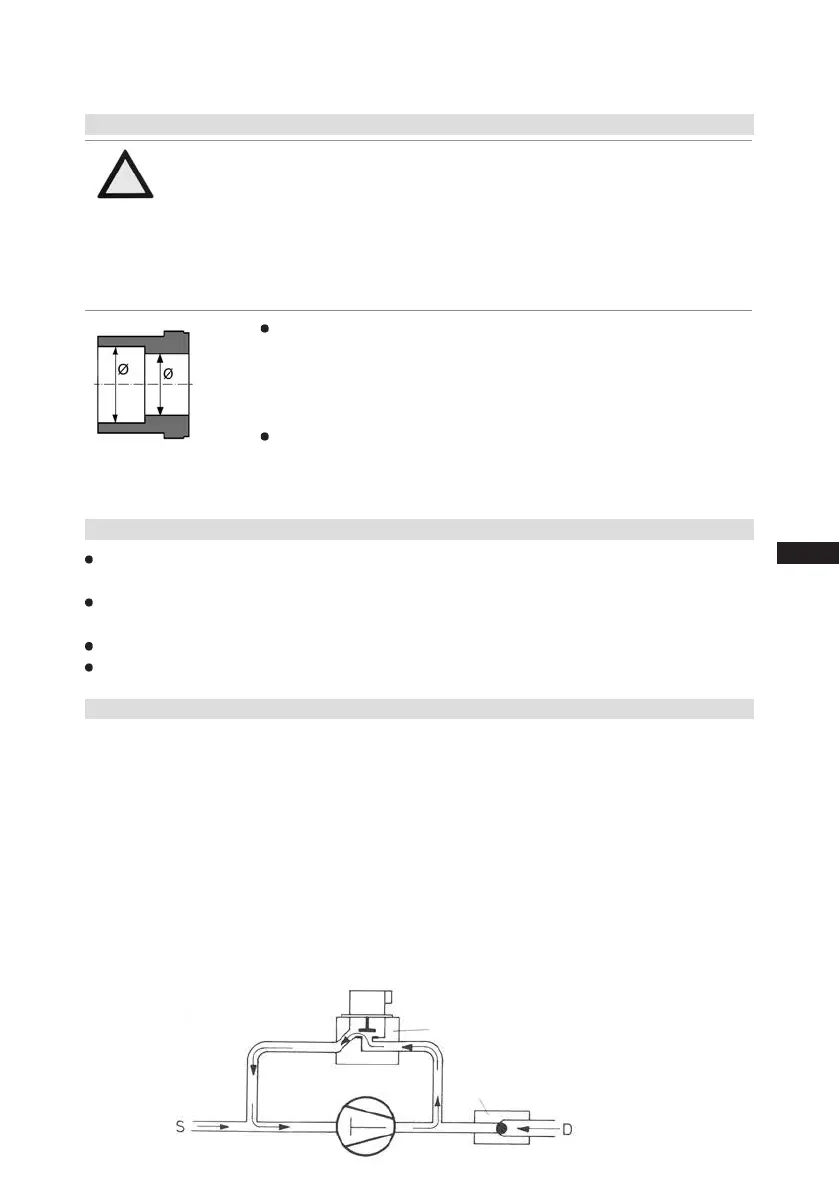

Operation:

When the compressor is started, a solenoid valve receives power via a time switch and opens a by-

pass between the discharge- and suction line. At the same time, a non-return valve in the discharge

lineclosesandpreventsabackowofrefrigerantfromthecondenser(Fig.5).

Thecompressorisnowshort-circuitedanddeliversfromtheoutowdirectlyintotheintake.The

pressuredifferentialconsequentlydecreasessubstantially.Asaresult,thetorqueonthedriveshaft

of the compressor is considerably diminished. The drive motor can now start with a low level of

startingtorque. As soon asthemotor andthe compressor reachtheirrated speed,the solenoid

valve closes and the non-return valve opens (Fig. 6). The compressor now works under normal load.

Solenoid valve actuated

Non-return valve closed

Loading...

Loading...