14

D

GB

F

E

I

Ru

96446-09.2020-DGbFEIRu

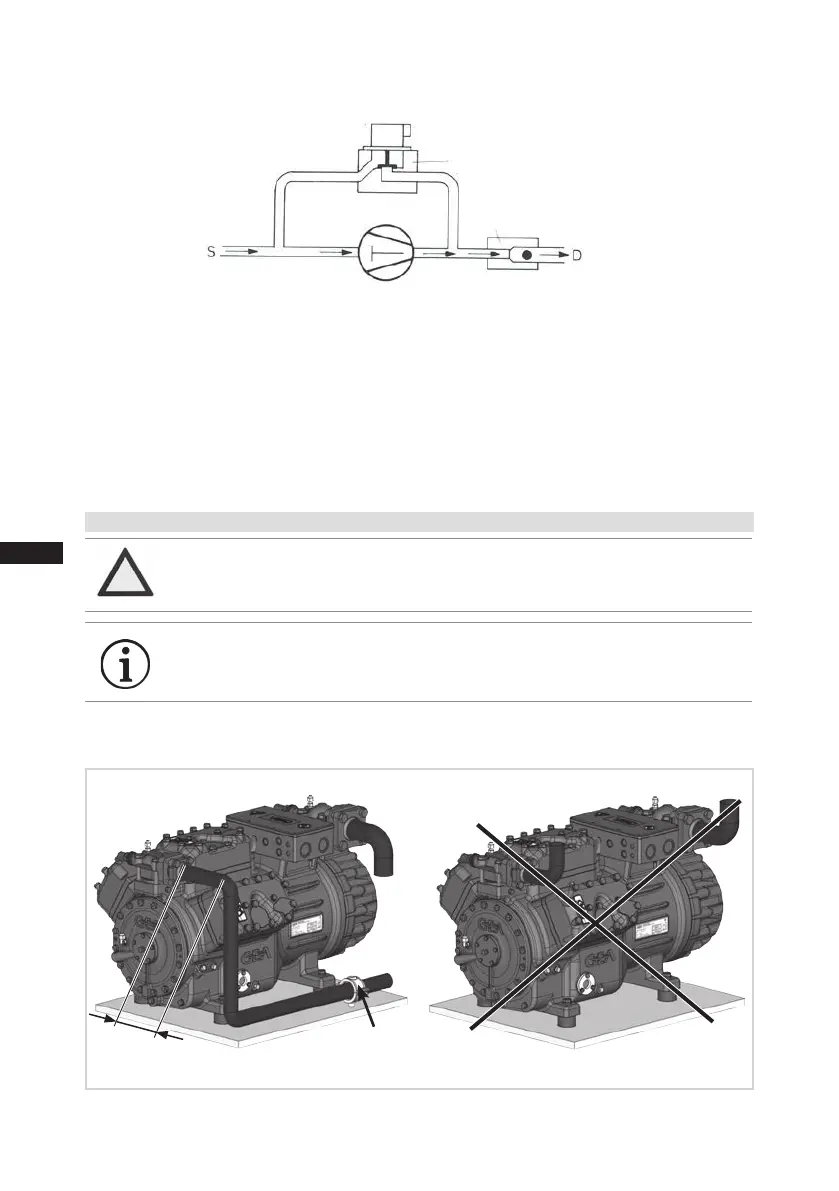

6 | Compressor assembly

Fig. 6

Rigid

fixedpoint

Fig. 7

As short as

possible

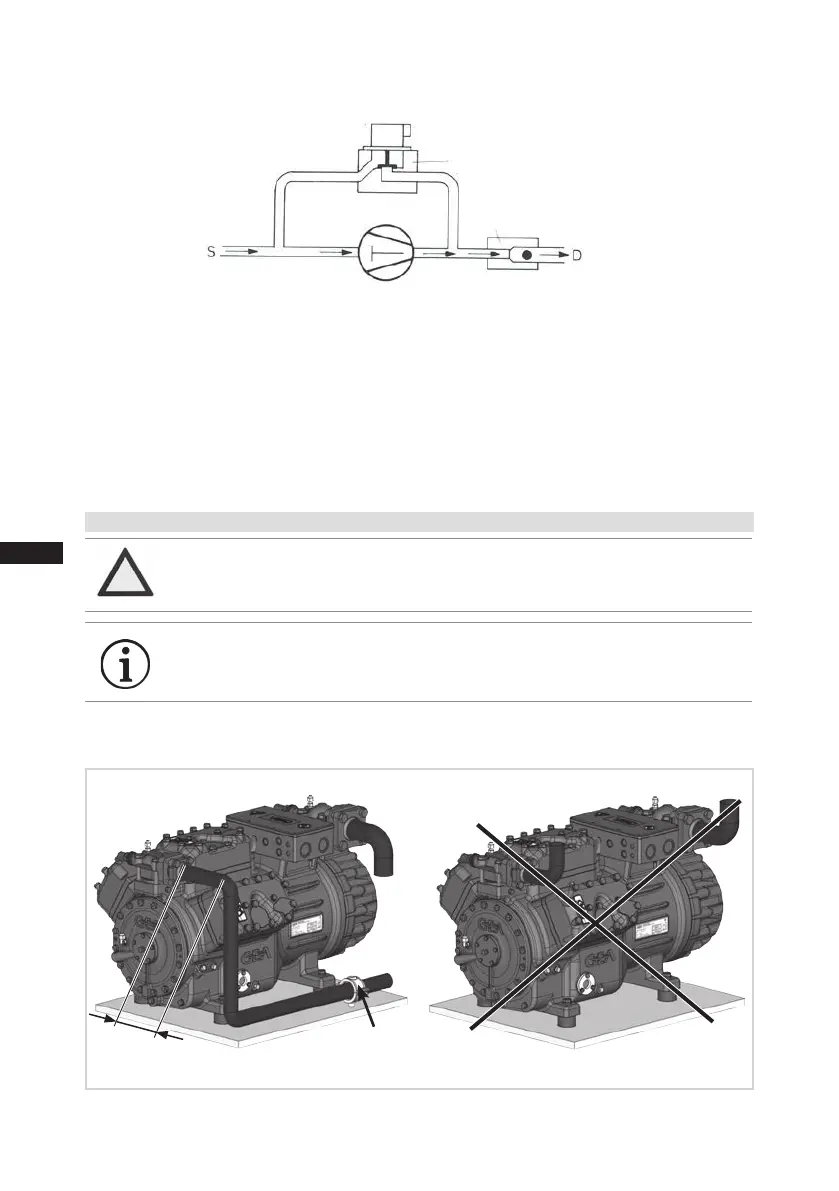

6.6 Layingsuctionandpressurelines

Aruleofthumb: Alwayslaytherstpipesectionstartingfromtheshut-offvalvedownwards

andparalleltothedriveshaft.

ATTENTION Improperlyinstalledpipescancausecracksandtears,theresult

beingalossofrefrigerant.

INFO Proper layout of the suction and discharge lines directly after

the compressor is integral to the system’s smooth running and

vibrationbehaviour.

Important:

- Start unloader may only be employed during the starting phase.

- Check the solenoid valve and the non-return valve regularly for tightness.

- In addition, we recommend to use a heat protection thermostat on the discharge side of the com-

pressor. This protects the compressor against thermal overloading. Connect the heat protection

thermostat in series on the safety chain of the control circuit, to switch off the compressor if

necessary.

- Follow these instructions to avoid thermal overloading.

Solenoid valve dead

Non-return valve open

Loading...

Loading...