30

D

GB

F

E

I

Ru

96446-09.2020-DGbFEIRu

9 | Maintenance

9.5 Decommissioning

Close the shut-off valves on the compressor. Drain the refrigerant (it must not be discharged into the

environment) and dispose of it according to the regulations. When the compressor is depressurised,

undo the fastening screws of the shut-off valves. Remove the compressor using an appropriate hoist.

Dispose of the oil inside in accordance with the applicable national regulations.

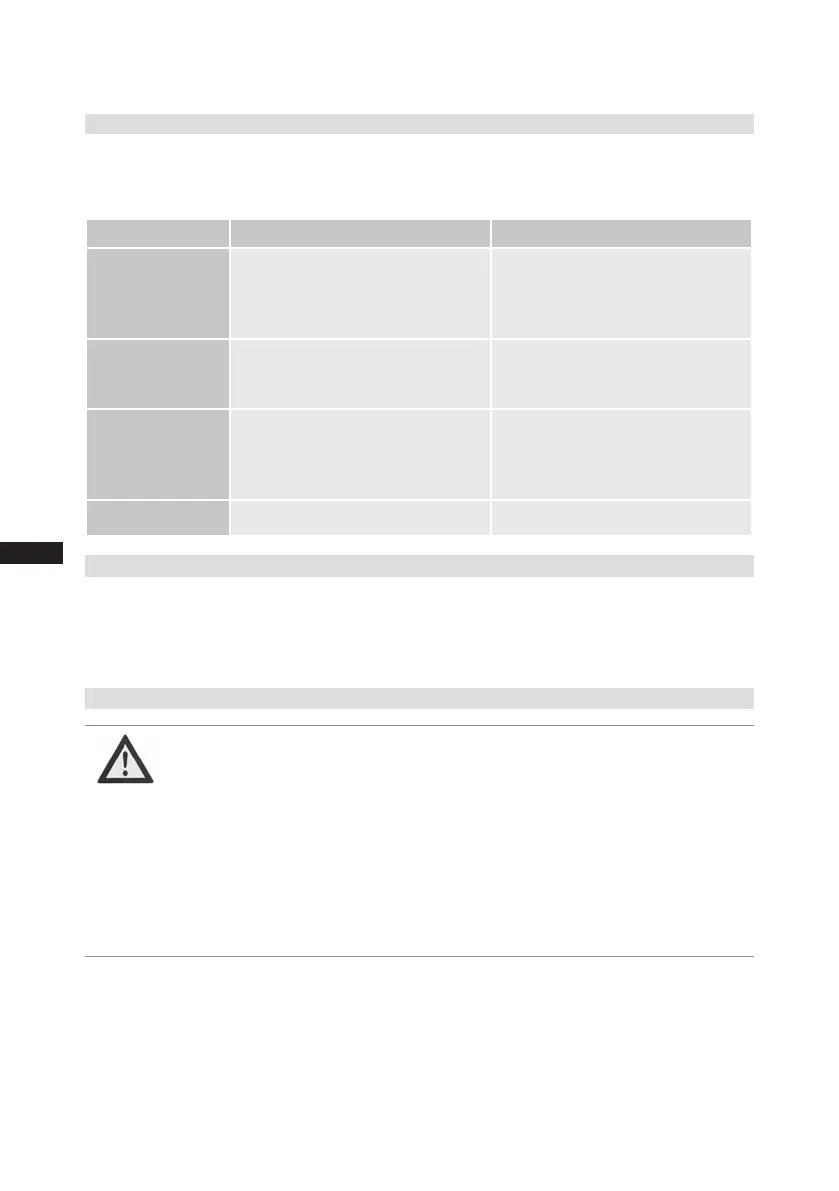

9.4 Extractfromthelubricantstable

Theoiltypelledasstandardinthefactoryismarkedonthenameplate . Thisoiltypeshouldbe

used as a preference. Alternatives are stated in the extract from our lubricants table below.

Donotmixoilswitheachother,useonlyonetypeofoil.

Refrigerants Bockstandardoiltypes

Recommended alternatives

HFC

(e.g. R134a, R407C,

R404A)

FuchsRenisoTritonSE55

Fuchs Reniso Triton SEZ 32

Esso/Mobil EAL Arctic 46

Sunoco Suniso SL 46

Texaco Capella HFC 55

HFO (e.g. R1234yf,

R1234ze, R455A,

R454C))

FuchsRenisoTritonSE55

FuchsRenisoC85E(from t

O

> 15°C)

---

HCFC (e.g. R22)

FuchsRenisoSP46

Fuchs Reniso SP 32

BP Energol LPT 46

Sunoco Suniso 3,5 GS

Texaco Capella WF 46

HC (e.g. R290)

FuchsSynth68

CPI 1516-68

9.6 Additionalinformationwhenusingammablerefrigerants

WARNING •Duringmaintenanceandrepair,itmustbenotedthathydrocarbon

and synthetic HFO refrigerants residues may dissolve in the

oil. Therefore,electricaltestsmust not be conducted while oil

remainsinthecompressor.

•If the compressor is to be removed from the system for

maintenance or repair, the remaining refrigerant must be

suctioned out and the compressor evacuated. The compressor

must then be filled with nitrogen (max. 0.5 bar) and sealed

gas-tight.

Loading...

Loading...