917387/BP0310 81

CHAPTER 7

MAINTENANCE

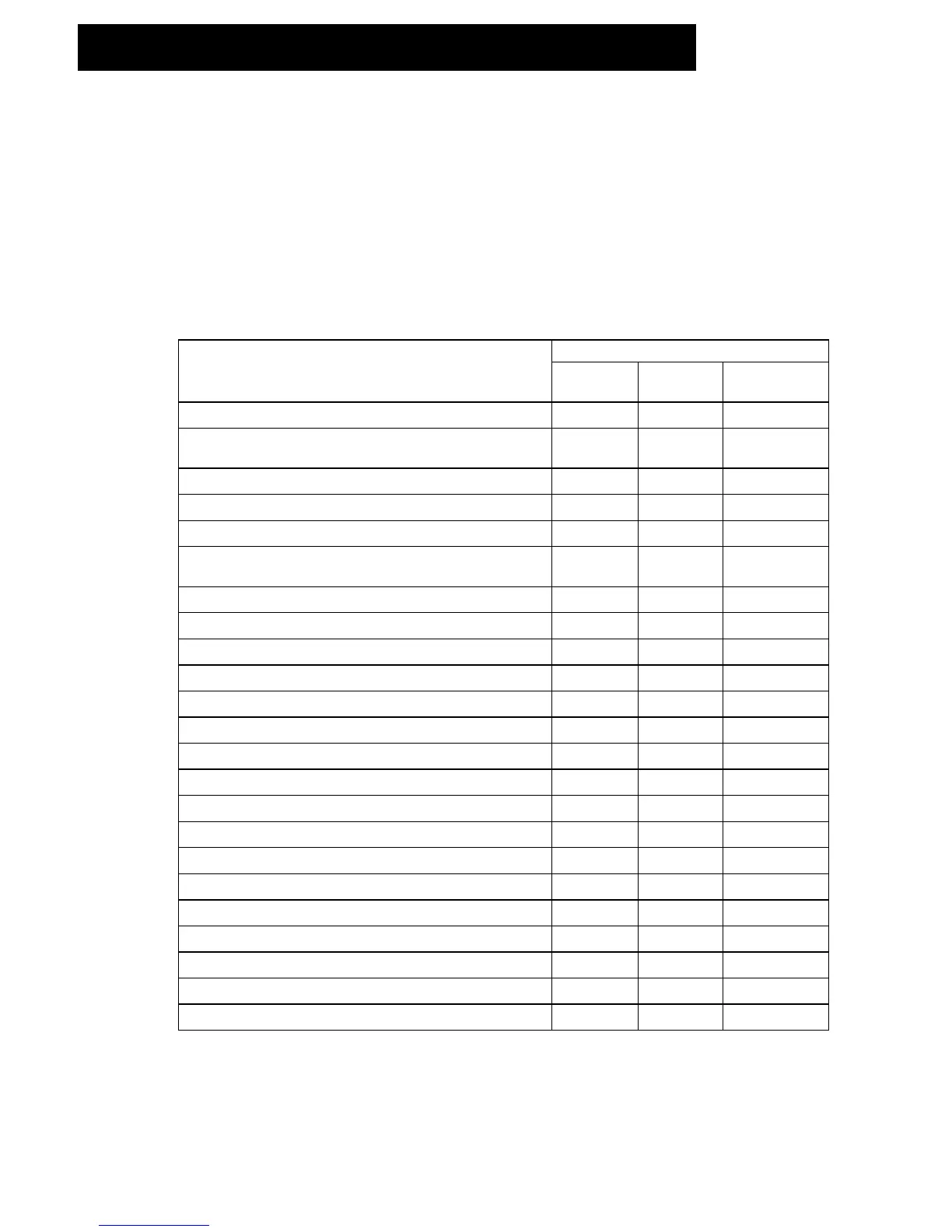

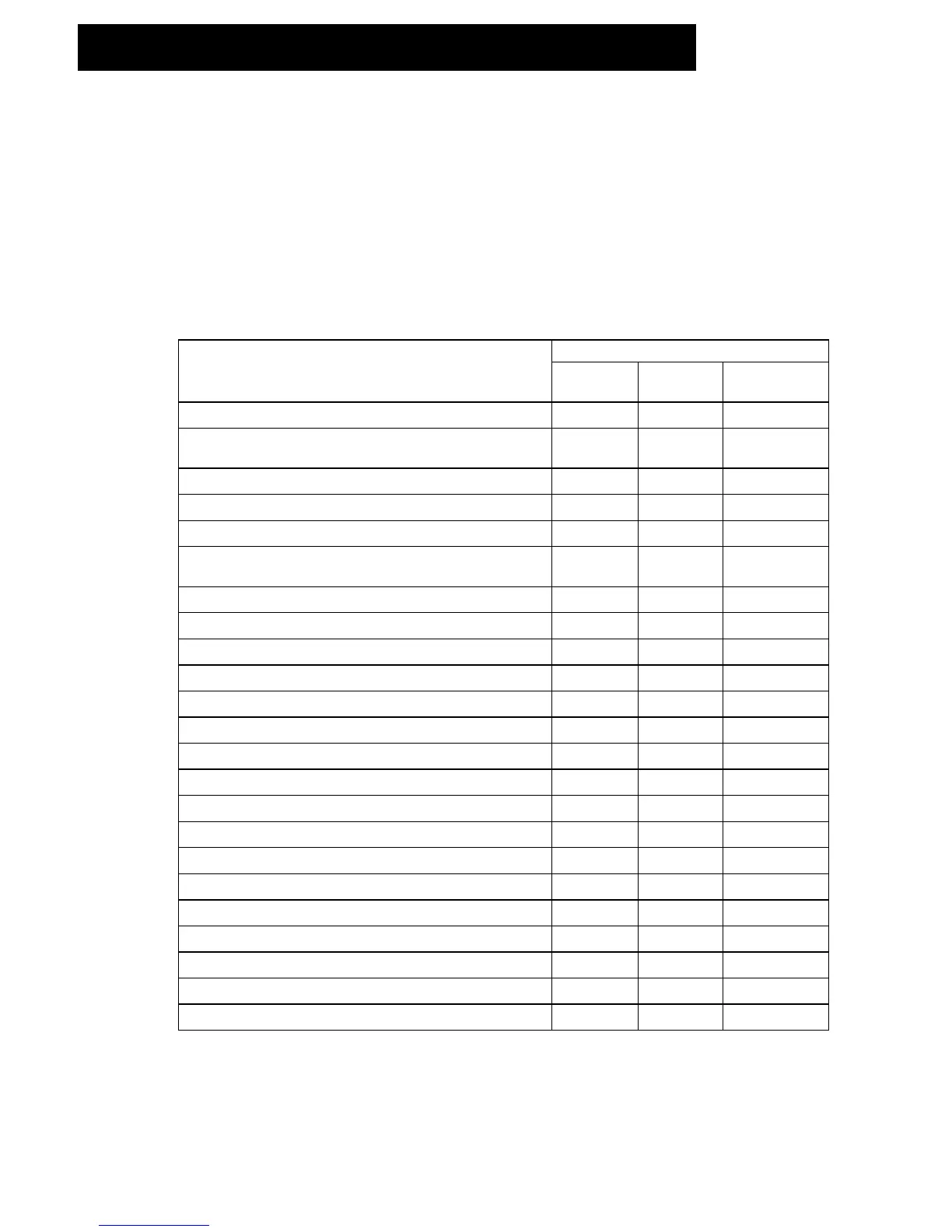

This Maintenance Interval chart was developed to match the Service chapter of

this manual. Detailed information on each service procedure is in the Service

chapter. A Maintenance Log follows this chart for recording maintenance per-

formed. Recording 10-hour (or daily) service intervals is impractical and is not

recommended.

Important: Under severe operating conditions, more frequent service than the

recommended intervals may be required. You must decide, based on your use, if

your operation requires more frequent service.

Service Procedure

Maximum Interval

10 Hours

(or Daily)

250 Hours

500 Hours

(or Annually)

Remove Foreign Material (page 54)

z

Check Engine Air Cleaner Restriction Indicator

(page 58)

z

Check Engine Oil Level (page 62)

z

Check Hydraulic Oil Level (page 67)

z

Check Tire Pressures (page 70)

z

Grease Lift Arm, Hitch, Cylinder Pivots and

Latch Pins (page 55)

z

Check Bucket Cutting Edge (page 68)

z

Test Safety Interlock System (page 20)

z

Check Coolant Level (page 69)

z

Clean Cooling System (page 69)

z

Check Drive Chain Tension (page 58)

z

Check Wheel Nuts Torque (page 68)

z

Check All-Tach

®

Pivot Torque (page 68)

z

Check Oil Level in Chaincases (page 57)

z

Check Alternator/Fan Belt Tensions (page 68)

z

Change Engine Oil and Filter (page 62)

z

Change Hydraulic Oil Filter (page 67)

z

Check Battery (page 71)

z

Check Engine Mounting Hardware (page 62)

z

Change Fuel Filter (page 62)

z

Change Hydraulic Oil (page 68)

Check and Drain Water Separator (page 63)

z

Change Chaincase Oil (page 57)

Perform the initial procedure at 2 hours then at “z” intervals.

Perform the initial procedure at 50 hours then at “z” or “” intervals.

Severe operating conditions.

Perform the procedure at 1000 hours.

Loading...

Loading...