- 16 -

INSTALLATION

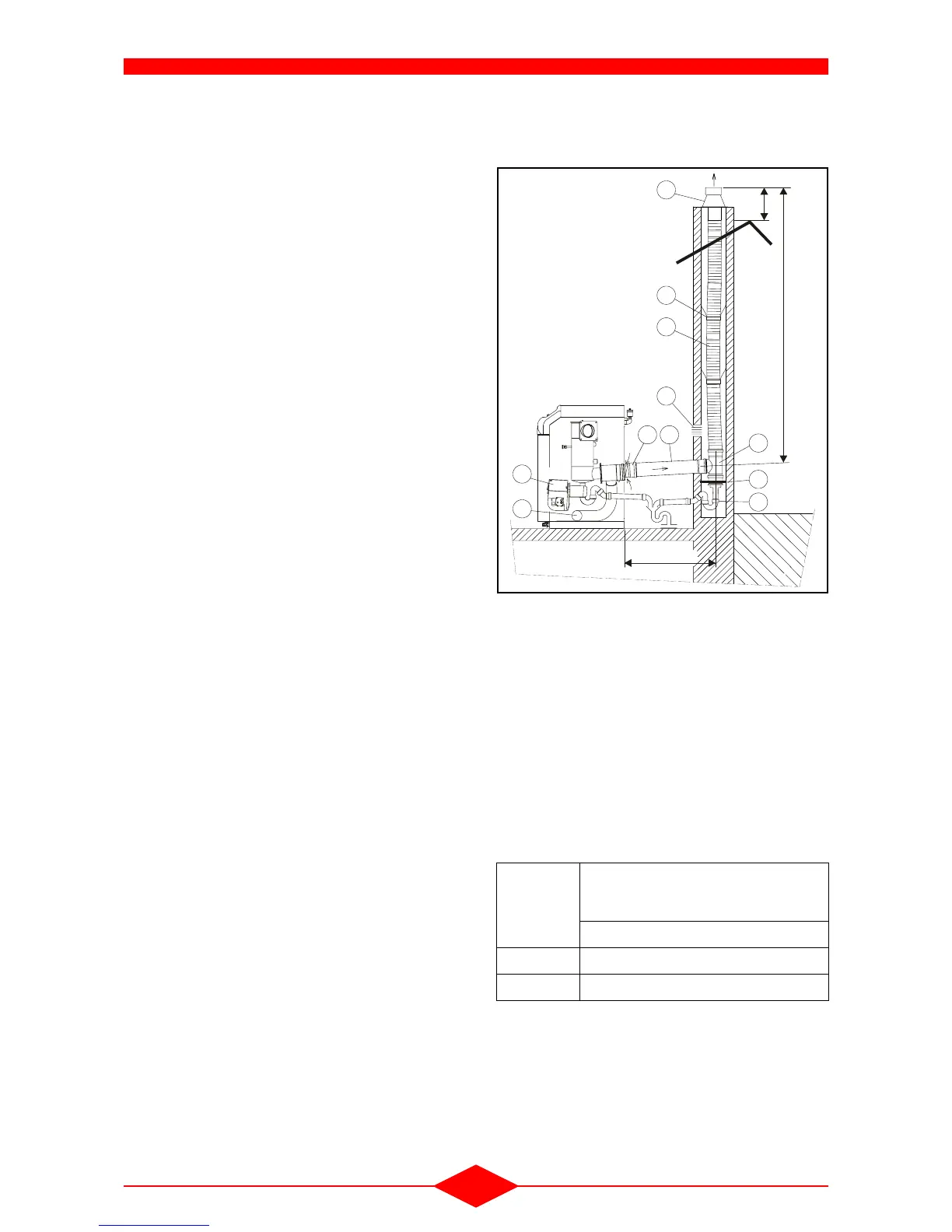

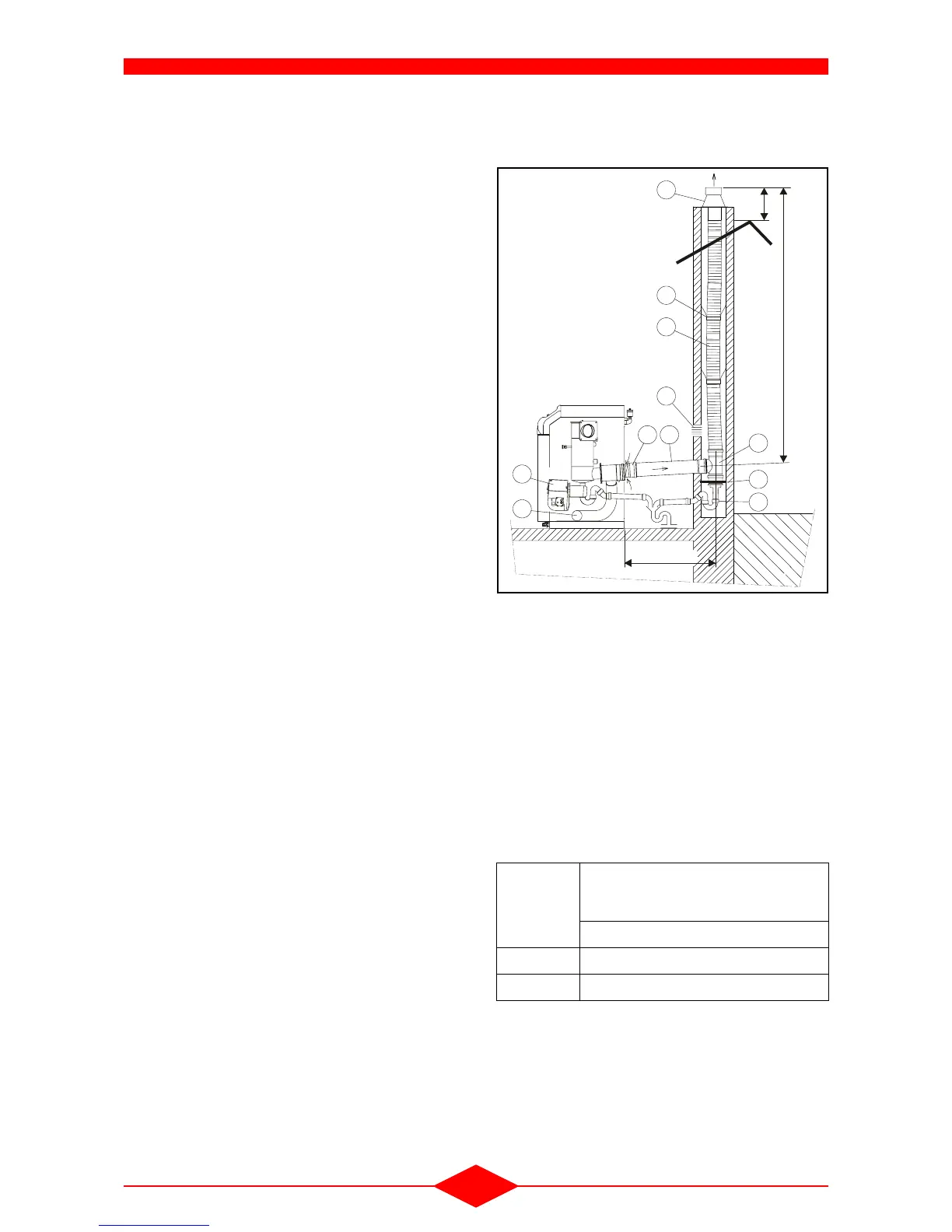

3.2.3 - Configuration with pressurized lining

(B

23p

)

Definition : Lining of an existing chimney flue by a

corrugated PP flue conduit of

∅ 110 according to

the height.

- The termination, specific to this configuration and

specified in the DTA, must have its outlet above

the roof (comply with the specification of the de-

cree of 22 October 1969),

- Do not use the hose for a horizontal assem-

bly: condensate may be retained.

- Fit a siphon (5) with a minimum 80 mm seal be-

tween the bleed T-bracket and the waste water

pipe,

- The bleed T-bracket at the foot of the flue is op-

tional when the vertical flue is short (L1 < 5 m),

- Ventilation for the flue (rep. 8) and the heating

system

(section 2 - chapter IV - INSTALLA-

TION) must be provided.

- If the boiler is installed in premises that have me-

chanical air extraction, ensure that this does not

cause negative pressure.

- The premises must never be fitted with other ap-

pliances using natural draft to operate.

- The air is sucked in by the burner directly from the

room in which the boiler is fitted.

- The burner must be equipped with the air damper

(item no. 2) in order to prevent heat losses due to

draft.

3.2.3.1 - Installation example

Accessories :

1) PPtl off-centre reduction

∅

80/110 (supplied with the

bleed T-bracket),

2) Air choke (supplied with the air damper kit),

3) PPtl tube

∅

110 L = 1 m (cut to the length required),

4) Bleed T-bracket

∅

110 (supplied with the off-centre re-

duction)

5) Siphon,

6) PP corrugated flue

∅

110,

7) Termination (above the roof)

8) Lining ventilation

9) Bleed T-bracket support

10)Chimney spacers

Note:

- Calculation of the diameters for the conduits to be

made according to EC standard EN 13 384-1.

- Each 45° elbow added reduces the total length al-

lowed by 0.5 m.

Models

Maximum permitted length L1 with

bleed T-bracket with horizontal

connection 1 m at conduit diameter

Conduit ∅ 110

FCX 22 C 20 m

FCX 30 C 15 m

6

4

1

3

8

21

2

L1

0,4 m

7

FCX-52-0

L2 = 1 m

maxi

9

5

10

Fig. 15

Loading...

Loading...