- 25 -

INSTALLATION

4 - CONDENSATE DRAINAGE

When connecting the condensate drain to the waste

water drain, it is essential:

- to maintain a downwards slope towards the drain,

The condensate drainage tubes must

either be buried or pass through a hea-

ted area to avoid any obstructions cau-

sed by freezing.

The condensate drainage siphon

should be checked regularly.

Before activating the boiler for the first

time, remove the condenser cover and

fill the siphon (rep 10) (

fig. 2 - page 7 -

chapter II - TECHNICAL SPECIFICA-

TIONS).

Note:

- The maximum production of condensates is

1.5

l/h (with underfloor heating low temperature

load 100 % load) which amounts to an average

daily production of 10 litres of condensates for a

15 kW installation - This low flow rate does not re

-

quire any specific treatment (extensive dilution in

the waste water). Nevertheless, if local regula

-

tions require waste to have a neutral pH, a con-

densate treatment tank must be installed

between the siphon and the waste water drain.

Accessories:

- Siphon (item no. 5)

- Tube ∅ 40 (item no. 6)

-Elbow ∅ 40 (item no. 7)

- Waste water drain (item no. 8)

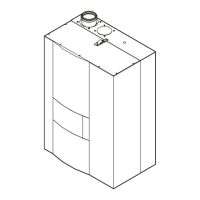

5 - ASSEMBLY OF ACCESSORIES DELIVERED WITH THE BOILER

- Install the bend (A) on the weld for bleed connec-

tion - 3/4" section, boiler side,

- Install the bleed (B) on the 3/8" section of the

bend (A).

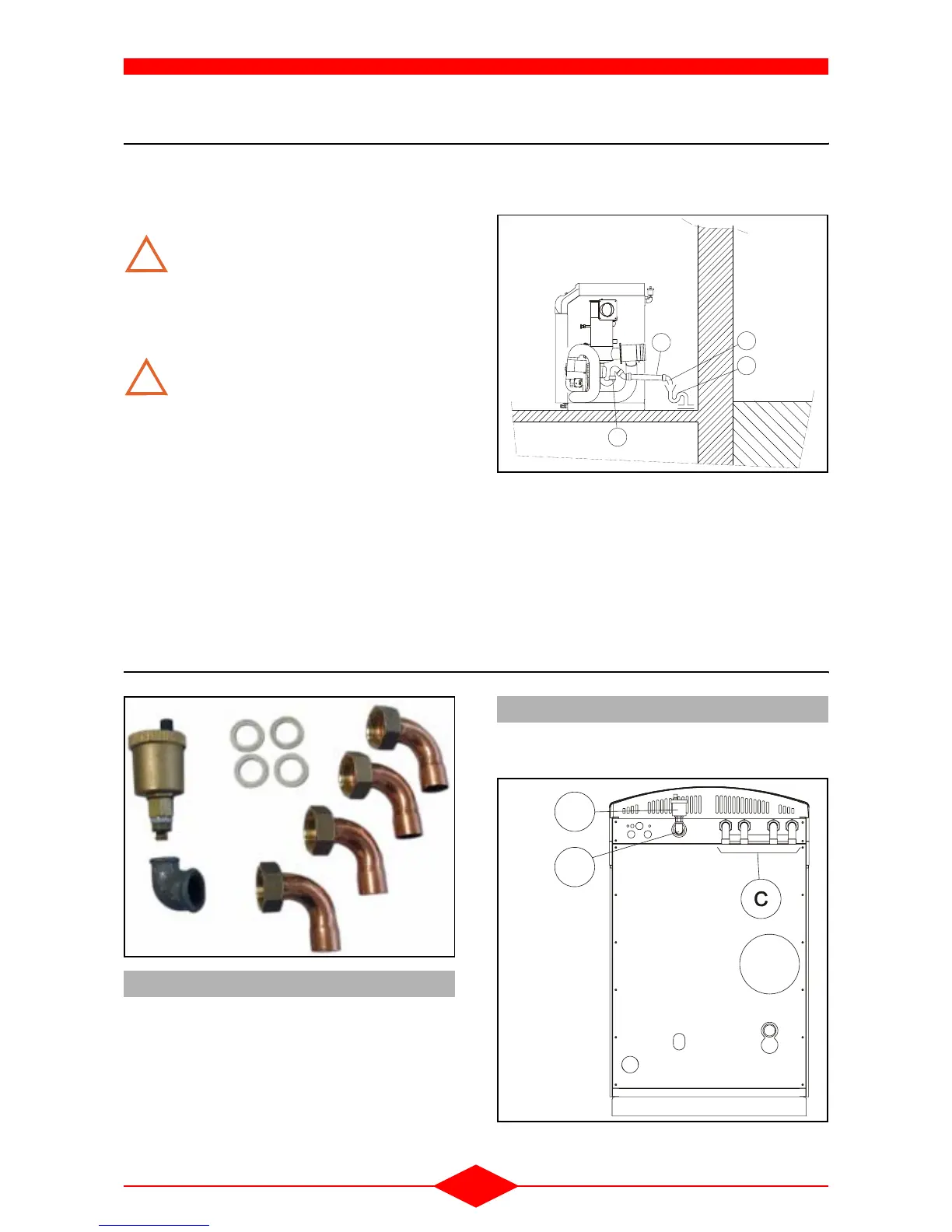

- Fit the 4 bends (C) and the related seals (D) on

the boiler outlet/return tubes.

!

!

5

6

7

8

FCX-30-0

Fig. 40

5.1 - Bleed + bend

Fig. 41

A

B

C

D

5.2 - 1" - Ø 22 bends + seal

F

Loading...

Loading...