Gaseous Fuel Systems

Installation Guidelines For Spark-Ignited Stationary Generators 27

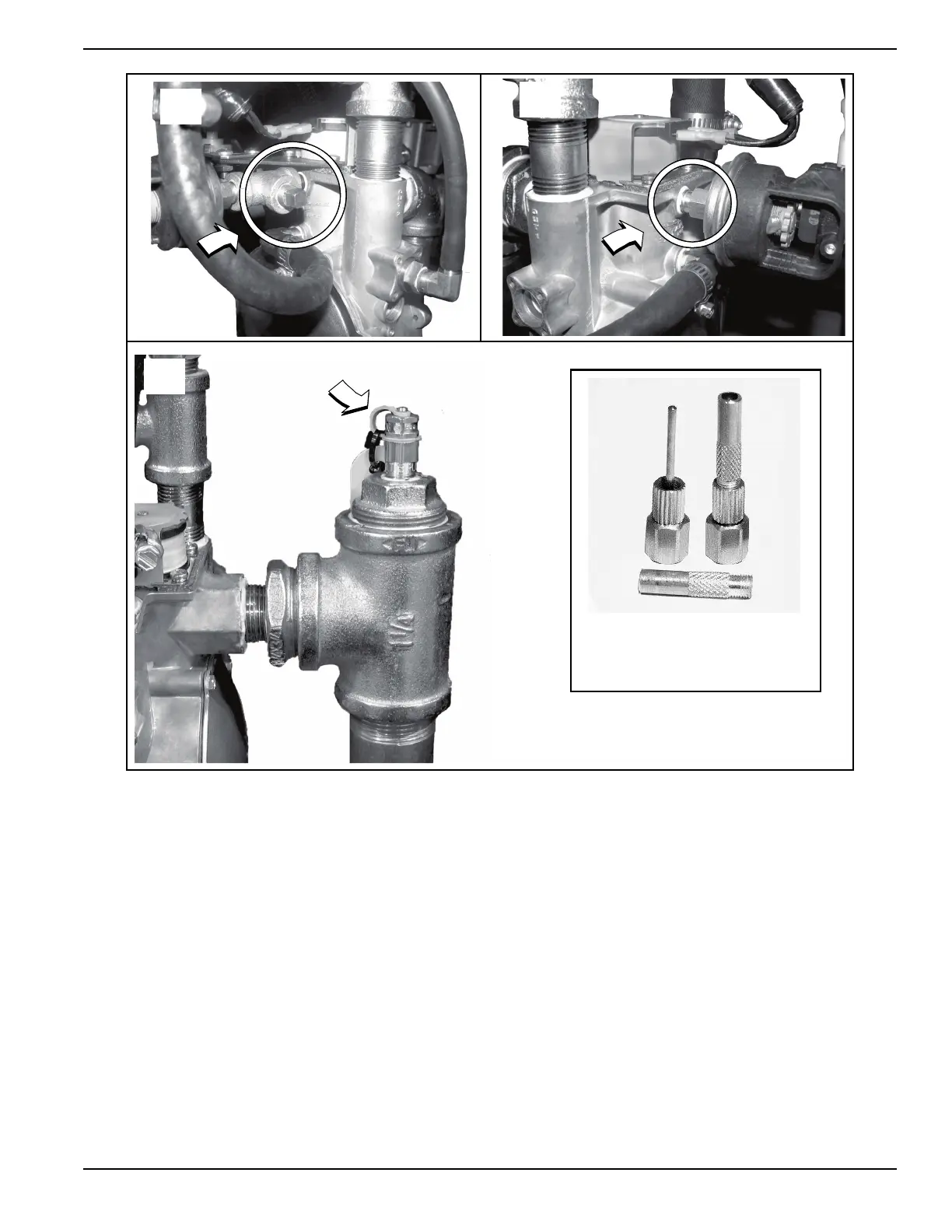

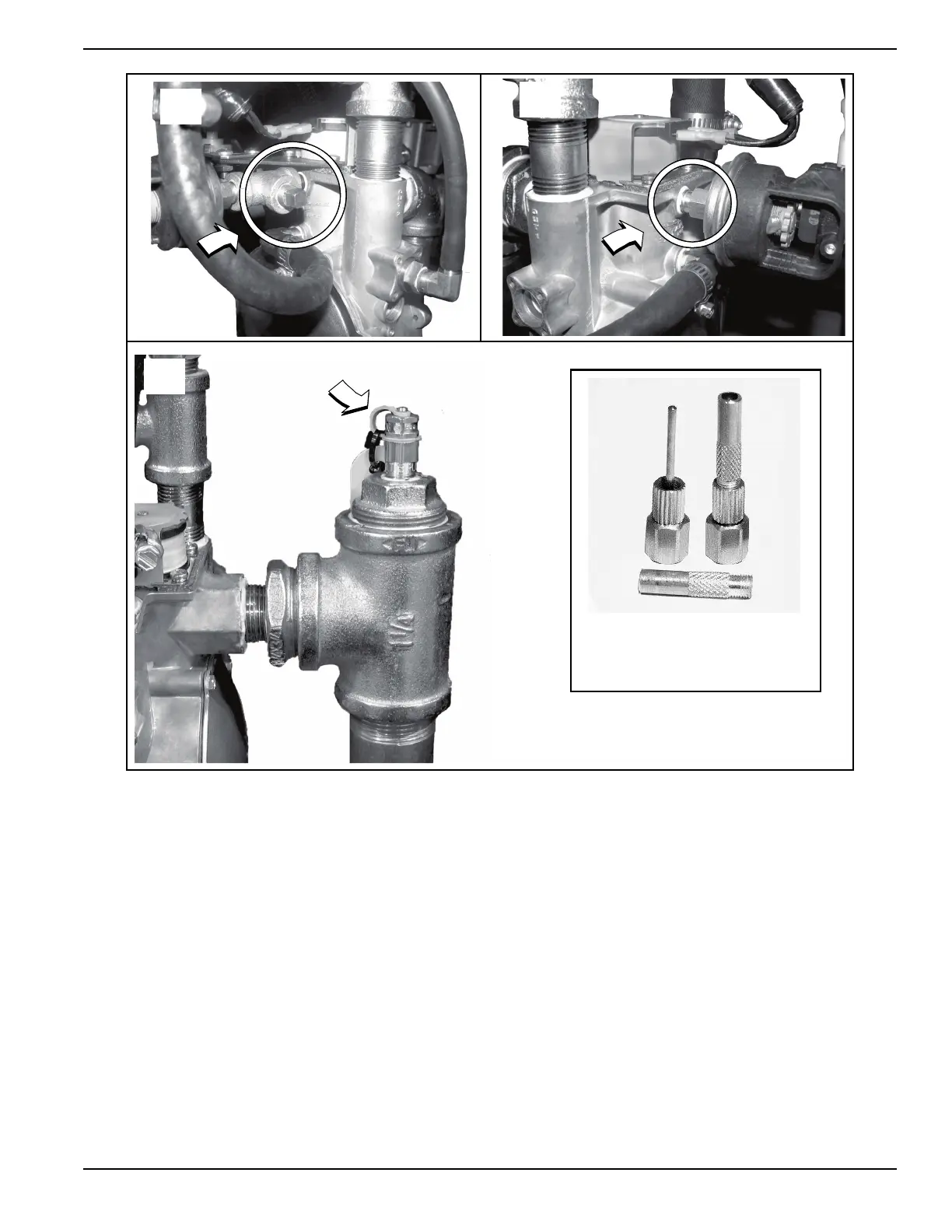

Figure 4-5. Fuel Pressure Test Points

Final Test Procedure

The following test must be performed at startup to docu-

ment and validate fuel system operation. It requires a

load bank connected to the unit, or a combination of load

bank and system load, to bring unit to its full rated kW

load capacity.

Measure fuel supply pressure under each of the following

conditions:

1. Static Pressure: Fuel supply pressure when unit is

not running. Must not exceed maximum pressure

listed in the unit specification sheet.

2. Cranking Pressure: Fuel supply pressure when

unit is cranking. Must not drop more than 1 in water

column (0.25 kPa) below Static Pressure or below

minimum pressure listed in the unit specification

sheet. If it does, it may indicate fuel supply piping is

not correctly sized, or primary fuel regulator is

incorrectly sized, or mounted too close to the gen

-

erator connection point. Unit may experience hard

starting, or will not perform as expected at full load

or during load transients.

3. Running—No Load Pressure: Fuel supply pres-

sure when unit is running at rated frequency and

voltage with no load. Must be at or slightly below

maximum pressure as listed in the unit specifica

-

tion sheet.

4. Running—Full Load Pressure: Fuel supply pres-

sure when unit is running with full rated load

applied (kW). Fuel supply pressure should not drop

more than 1–2 in water column (0.25–0.50 kPa)

from the Running—No Load Pressure and must

NEVER drop below minimum pressure listed in the

unit specification sheet.

A

B

C

Gauge Adapter

1/8 Inch Diameter Probe

Part No. 0K2341

009107

Loading...

Loading...