Electrical System

30 Installation Guidelines For Spark-Ignited Stationary Generators

Connecting Control Circuit Wires

Control system interconnections may consist of N1, N2,

and T1, and leads 23 and 194. The generator control wir-

ing is a Class 1 signaling circuit. See instruction manual

o

f specific engine generator for wiring connection details.

Recommended wire gauge sizes for wiring depends on

length of wire, as recommended in the following chart:

Exception: Conductors of AC and DC circuits, rated

1,000 volts nominal or less, shall be permitted to occupy

the same equipment, cable, or conduit. All conductors

shall have an insulation rating equal to at least the maxi-

mum circuit voltage applied to any conductor within the

e

quipment, cable, or conduit. See NEC 300.3(C)(1).

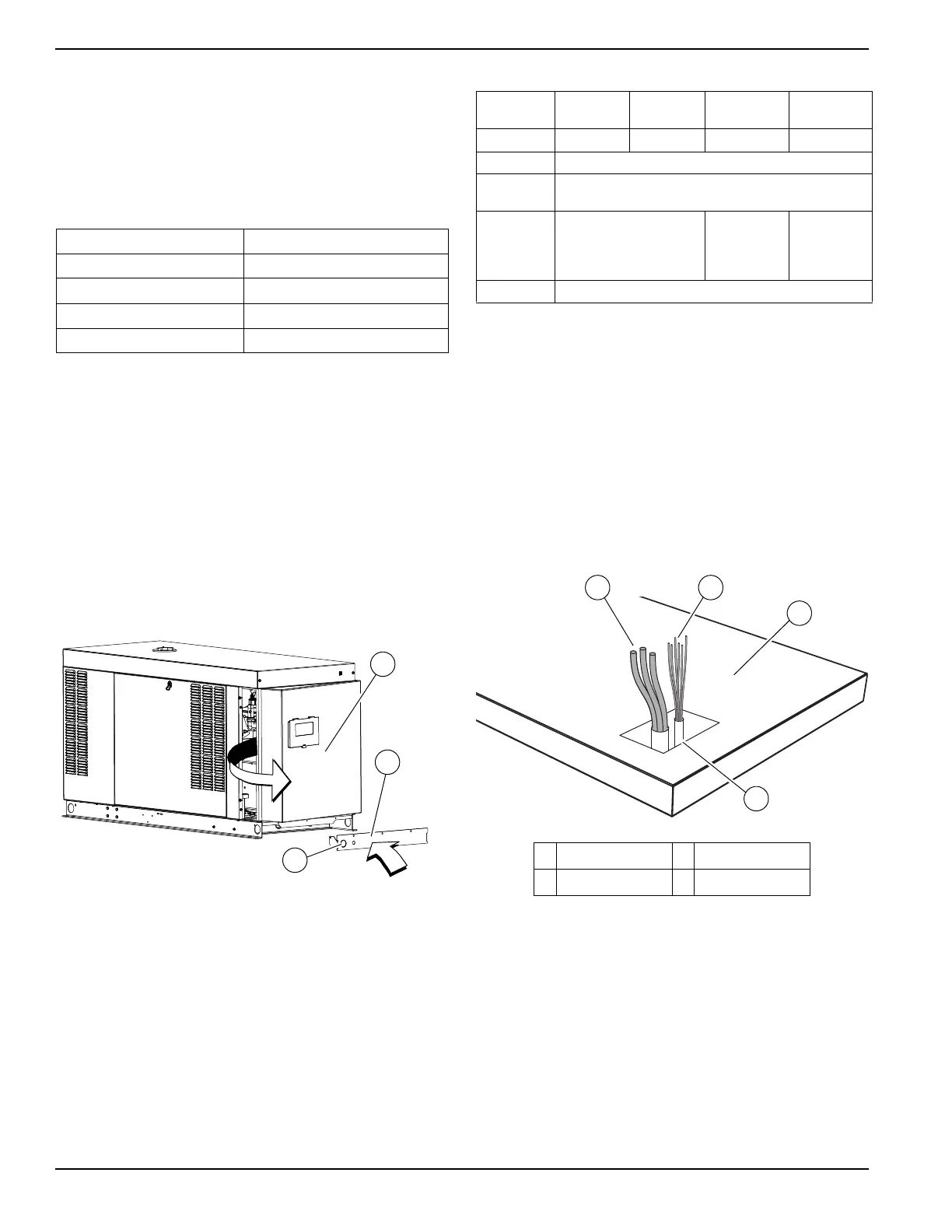

Removing Rear Panel and Stub-Up

Cover

1. See Figure 5-2. Remove six screws with nylon

washers to release rear panel (A) from enclosure.

For

best results, rotate left side of panel outward

away from enclosure before disengaging right side.

Figure 5-2. Remove Rear Panel and Stub-Up Cover

2. Remove f

our screws with nylon washers to release

fascia from control panel.

3. Th

e stub-up cover (B) and five screws with flat

washers are shipped loose and found inside the

enclosure. An optional knock-out (C) is provided.

Table 5-1. Frame Breakers

Frame

Breaker

Generac 225

AF 2 Pole

Generac 225

AF 3 Pole

Generac 400 AF

2 Pole

Generac 400 AF

3 Pole

Range

125A-200A 50A-200A 225A-400A 225A-400A

Wire type

Cu/Al

Wire temp.

rating

167 °F

(75 °C)

Lug AWG

range

(number of

co

nductors)

6-350 kcmil (1) 1/0 -250 kcmil (2)

or

4-600 kcmil (1)

1/0-250 kcmil (2)

or

4-600 kcmil (1)

Lug torque

375

in-lbs

(42.37 Nm)

NOTE: Generac frame breakers are rated at an 80%

continuous load rating. Frame breaker torque specs are

on the breaker data tag.

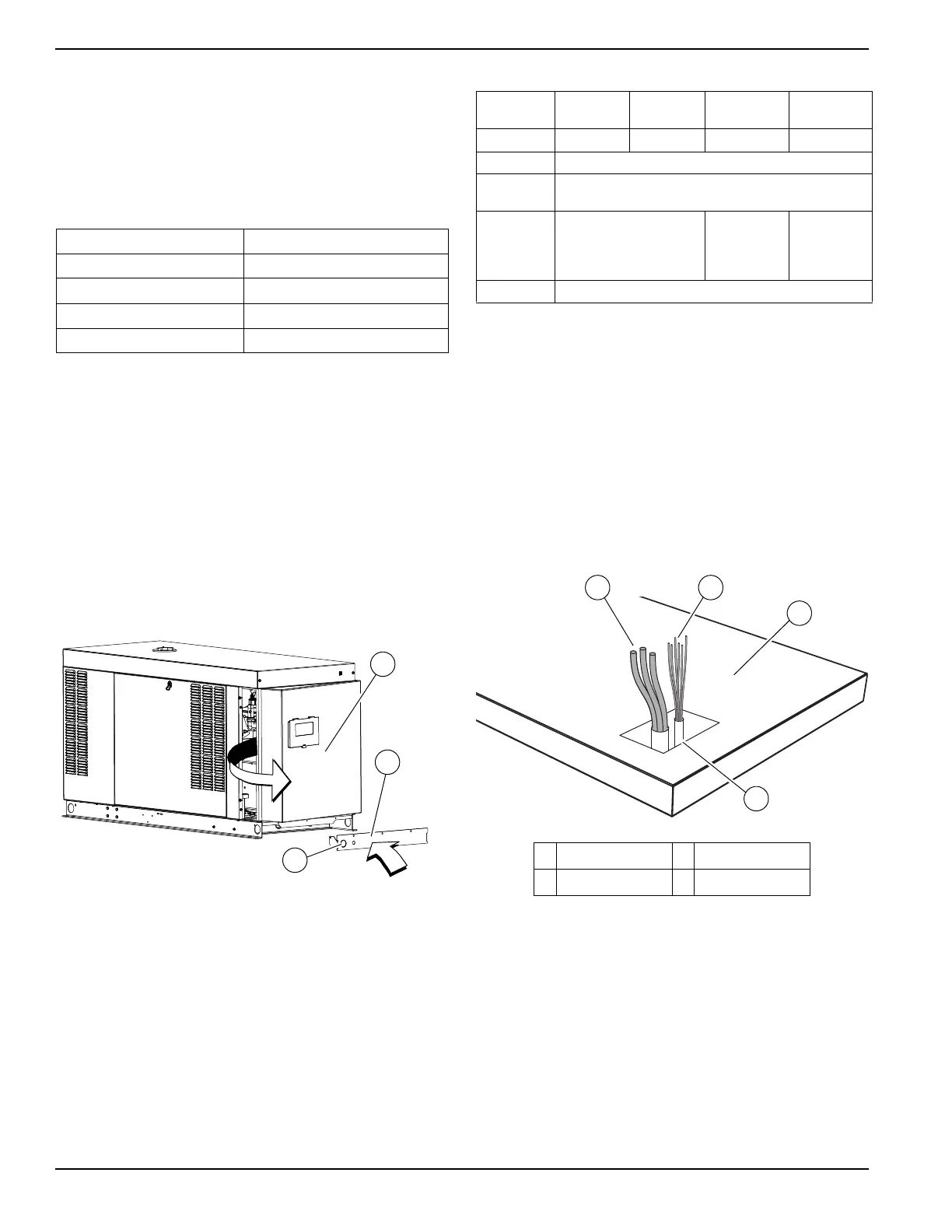

Typical Load Leads and Control

Wiring in Stub-Up

Figure 5-3 is for reference only. See installation drawings

for unit-specific details.

NOTE: See

300.3(C) and Article 725 in the NEC for rout-

ing of control wires and power wires.

NOTE: A single conduit is permitted.

Figure 5-3. Typical Load Leads and Control Wiring in

Stub-Up

Customer Load Wiring

Customer load wiring consists of single-phase or three-

phase connections between generator main line circuit

breaker (MLCB) and transfer switch. The wiring connects

to lugs E1, E2, (and E3, if three-phase on MLCB), neu-

tral, and equipment ground at generator, and runs to cor-

responding lugs in transfer switch. All load wires, neutral,

an

d ground should be marked and terminated in the cor-

rect lugs in transfer switch. V

erify all wiring is correctly

mounted and terminated at appropriate connection points

Maximum Wire Length Rec

ommended Wire Size

1–115 ft (0.30–35 m) No. 18 AWG

116–185 ft (36–56 m) No. 16 AWG

186–295 ft (57–89 m) No. 14 AWG

296–460 ft (90–140 m) No. 12 AWG

A Load leads C Stub-ups

B Control wiring D Concrete pad

Loading...

Loading...